MarcW

Established Member

Hello all,

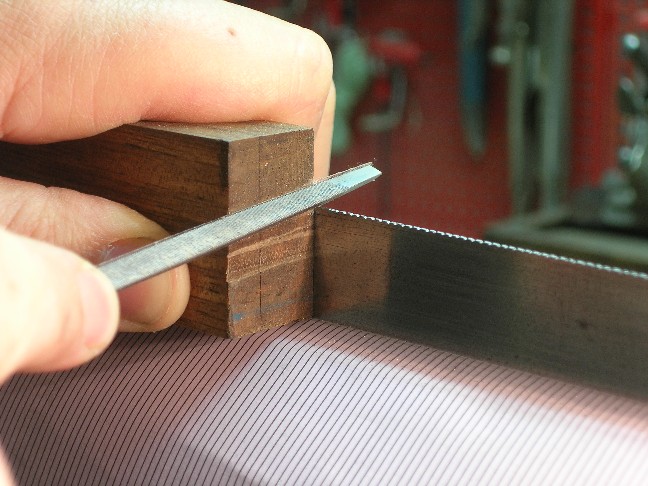

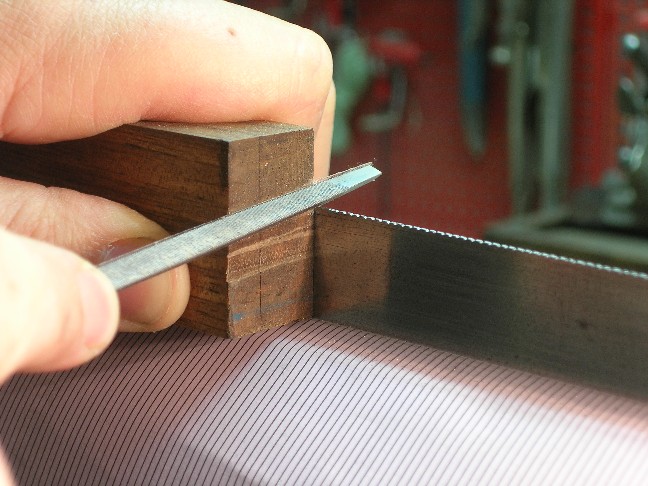

I retoothed an old Tyzack and Son saw today. Having read how Leif Hanson does this with a sheet of paper, I thought it would work for me too. But hélas... I am not that skilled #-o . So I decided I'd need something like a fence, or a jig to properly space the teeth. The saw has 10 inch of length and 15 tpi, finest I did before was 13 tpi, a very pleasant size, much more sympathic for eyes of my age :roll: .

My jig is nothing else than a piece of scrap. Placing the corner of the scrap on a line of the sheet, aligning the file with the scrap, giving the blade a stroke with the edge of the file creates a small indentation. First I bruised the wood and then fixed a bit of tape on the vertical side of the file, in order to not change the tpi by working towards the other end. The whole worked fine, well not exactly the first time, but training on some scraper blades helps much.

Anybody proceeds otherwise, something I didn't tumble over yet? My scrap requires some practice (I didn't have at the moment I made the pic) Later on I placed the sheet and the scrap behind the blade. Aligning the file was much easier. Results were improved.

Regards, Marc

I retoothed an old Tyzack and Son saw today. Having read how Leif Hanson does this with a sheet of paper, I thought it would work for me too. But hélas... I am not that skilled #-o . So I decided I'd need something like a fence, or a jig to properly space the teeth. The saw has 10 inch of length and 15 tpi, finest I did before was 13 tpi, a very pleasant size, much more sympathic for eyes of my age :roll: .

My jig is nothing else than a piece of scrap. Placing the corner of the scrap on a line of the sheet, aligning the file with the scrap, giving the blade a stroke with the edge of the file creates a small indentation. First I bruised the wood and then fixed a bit of tape on the vertical side of the file, in order to not change the tpi by working towards the other end. The whole worked fine, well not exactly the first time, but training on some scraper blades helps much.

Anybody proceeds otherwise, something I didn't tumble over yet? My scrap requires some practice (I didn't have at the moment I made the pic) Later on I placed the sheet and the scrap behind the blade. Aligning the file was much easier. Results were improved.

Regards, Marc