OK

I have done more work on the guitar but got a bit carried away and didn't take any photo's.

I did make a small error when gluing the filleted headstock to the neck, It slipped a fraction in the clamps and I didn't notice until it had dried so is a very small amount out. I did think of starting again but just couldn't face it. I was out by a very small amount but by the time you get to the top of the headstock it is probably about 1 - 2 mm.

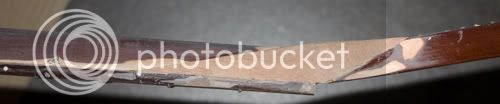

The joins are very tight, what looks like gaps in the photo's are just shadows

Here is the state of play at present. Just roughly shaped, still more work to do with the scraper and sandpaper. To date I have used some rasps, card scraper and sand paper to shape it to this state.

I have learnt quite a bit.

1. Guitars are really difficult to hold on a bench, they are both fragile and a very awkward shape.

2. Keep checking as the glue cures as the awkward shape makes the parts very difficult to clamp.

3. I can actually saw and plane two very flat and accurate surfaces, yippee. (Even though I cannot glue them together straight!

)

4. I must not rush things.

I was tempted to allow this thread to die as I was so annoyed that I had let the clamps slip but I thought I would just own up and confess all. As I said before the guitar was free and this was a bit of an experiment so great for learning some new things.

So I am now thinking of the finish.

Would the original have been cellulose?

Mick