I'm afraid I'm with Setch on this one (out of pure sad experience).

The cheap Takamine that I had to do was free on Freecycle..a lady had given up trying to have it fixed and decided to give it away. I still have that guitar and it is my favourite (until I finish my Martin build sometime in the 22nd Century!

)

You can see from the photo below...my break was along the mahogany grain right up to half way down the headstock and because this was a one piece neck....it was going to happen again...

You can just see the first repair to the left of the new break...the Titebond held firm...it's just the nature of these thin neck/headstock transitions. It may look sexy but under string tension...one ding...however light and the grain will sheer.

If I wanted this to be a guitar again...I would have to change the structure of the transition...and this is probably what you will need to do but from the back.

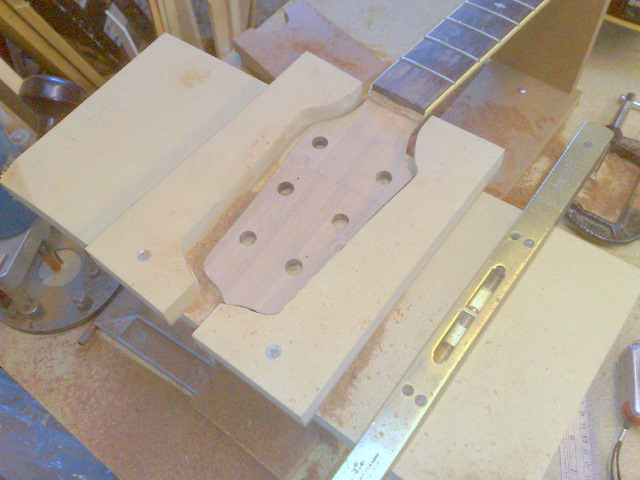

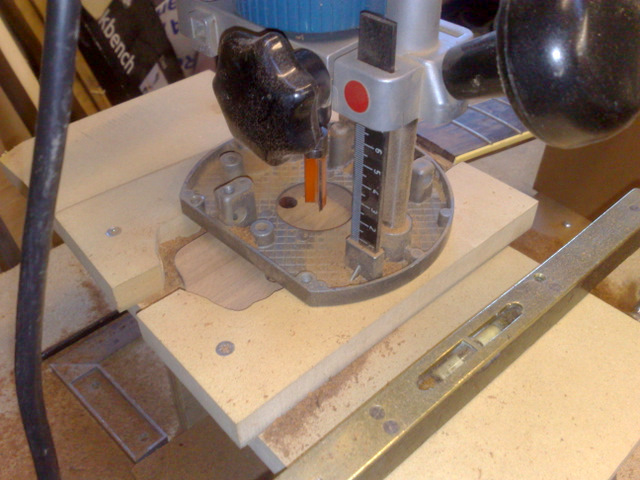

In this shot...the neck/headstock transition is mounted in a quick MDF jig level to enable me to route the entire top end out.

The walnut is then used to give a hard top piece on the headstock and stop the straight grain problem....laminated in place...

You can't see it here but I drilled two dowel holes deep into the neck and inserted two pieces of walnut right in deep....and into the bottom piece of the remaining headstock then put the cap on...

....not a great match...but I was going to stain it anyway....

The final result is not going to win any prizes in the hidden repair category but it was my first attempt and like you said, you can learn on something that will not matter too much if it does screw up rather on a Taylor or Martin which would leave me cold! :wink:

It's been "settling" for over a year now of constant playing....so next time I change the strings...I will match in some vintage headstock binding to finish it off!

My friend in the USA who worked for Gibson...says that this is a common fault with Les Pauls for the very same reason. He would route out two channels on the back....across the transition...bed in West System epoxy and carbon fibre rod (roughed up with 60 grit) and leave space at the top which was then filled in with maahogany patch fillets....and make good.

I think this is your best option...short of replacing the neck.

Hope this helps

Jim