Not exactly, on my system the extractor is switched remotely by opening the blast gate, rather than the magnetic sensors of the now discontinued Axminster system.

A small micro switch attached to the blast gate is arranged to complete a circuit on the low voltage (in my case 24v provided by a doorbell transformer in the same box) side of a relay, which in turn swiches on the extractor. When the blast gate is closed the circuit is opened, and the extractor is turned off. Using bell wire, all the blast gates on the system have micro switches connected in parallel so that the system operates from any of the take off points.

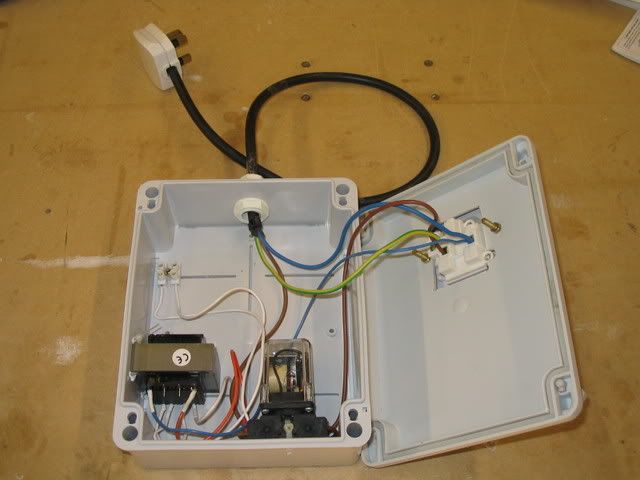

Here's the inside of the control box, the 2 white wires in the connector block (top left) are the contacts for the low tension circuit.

and here's the front. The socket on the front is switched by the relay and is where the extractor plugs in. The whole lot is connected to the mains via the plug on the flylead.

and here's the blast gate with microswitch:

I attached the switches with small brackets made from aluminium. By drilling a hole in the moving plate the armature is allowed enough movement to release the switch when the blastgate is closed.

Its all a little "Heath-Robinson", and I don't suppose for a minute it complies with half the rules and regulations needed for any kind of commercial situation. But the circuit was designed by a very competant electrician, and was put together carefully by yours truly. I'm completely confident of it's safety, it works brilliantly, and cost me next to nothing - about £25 for the control box, plus a roll of bell wire and a bunch of microswitches from Maplins at about £2 each.