I made several modifications to my Record Power BS350S bandsaw and documented them here in case anyone with a similar bandsaw was interested.

Here are the modifications I made so far. I’ll update the list below with links to the other threads as I add them::

1. Upgrade upper and lower blade guides with the Rikon tool-less kit made for the Rikon 10-324 and 10-325 bandsaws.

2. Add an electrical outlet to the upper frame so I can power the magnetic base LED lamp.

3. Add blade shroud to improve dust collection.

4. Rip Fence Upgrade

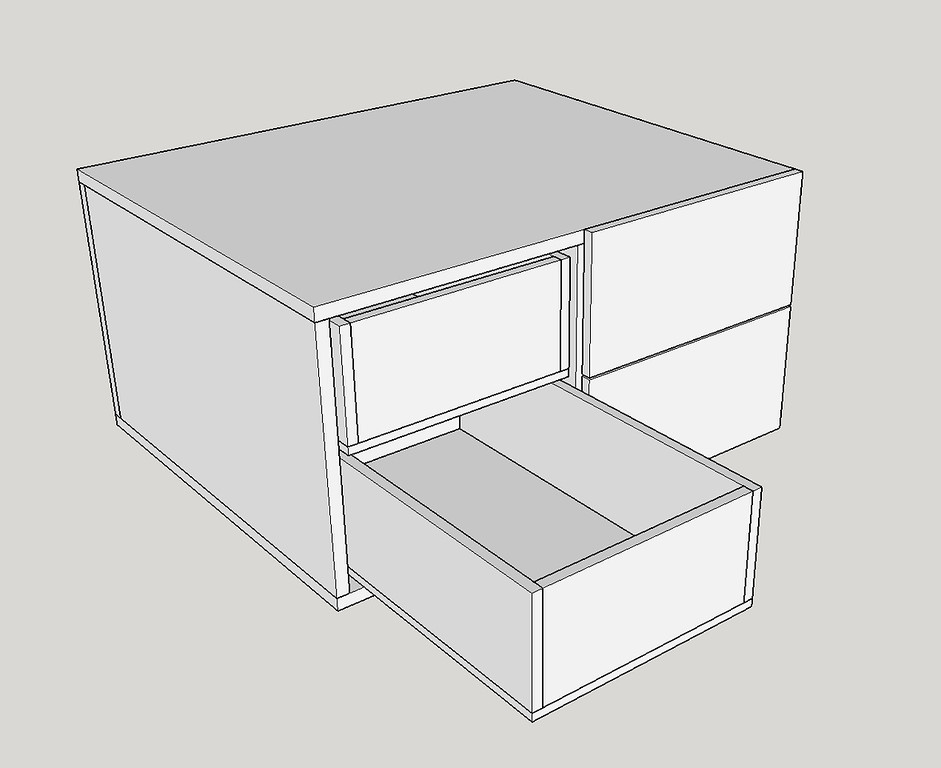

5. Replace the stock wheeled base with a sturdy cabinet with drawers, locking casters, and push handle.

=====

Anyone with a Record Power bandsaw mounted on the OEM mobility base might agree that it is not very good and becomes less mobile over time. I had lots of plywood and hardware left over from other projects, or canceled projects, so I built this base mostly with what I had on hand. The only items I bought specifically for this bandsaw base were the drawer pulls, two more dual-locking casters, and the pipe clamps for the handle. I knew I could improve on the Record Power base and would add what I hope will be plenty of storage.

Here is the Record Power Mobility Base in all it's glory. The casters are already collapsing, and the feet drag on the floor when the base is elevated for moving. Imagine metal fingernails on a tile blackboard.

The base is disassembled and ready for the recycling bin.

Here are the modifications I made so far. I’ll update the list below with links to the other threads as I add them::

1. Upgrade upper and lower blade guides with the Rikon tool-less kit made for the Rikon 10-324 and 10-325 bandsaws.

2. Add an electrical outlet to the upper frame so I can power the magnetic base LED lamp.

3. Add blade shroud to improve dust collection.

4. Rip Fence Upgrade

5. Replace the stock wheeled base with a sturdy cabinet with drawers, locking casters, and push handle.

=====

Anyone with a Record Power bandsaw mounted on the OEM mobility base might agree that it is not very good and becomes less mobile over time. I had lots of plywood and hardware left over from other projects, or canceled projects, so I built this base mostly with what I had on hand. The only items I bought specifically for this bandsaw base were the drawer pulls, two more dual-locking casters, and the pipe clamps for the handle. I knew I could improve on the Record Power base and would add what I hope will be plenty of storage.

Here is the Record Power Mobility Base in all it's glory. The casters are already collapsing, and the feet drag on the floor when the base is elevated for moving. Imagine metal fingernails on a tile blackboard.

The base is disassembled and ready for the recycling bin.