sploo

Somewhat extinguished member

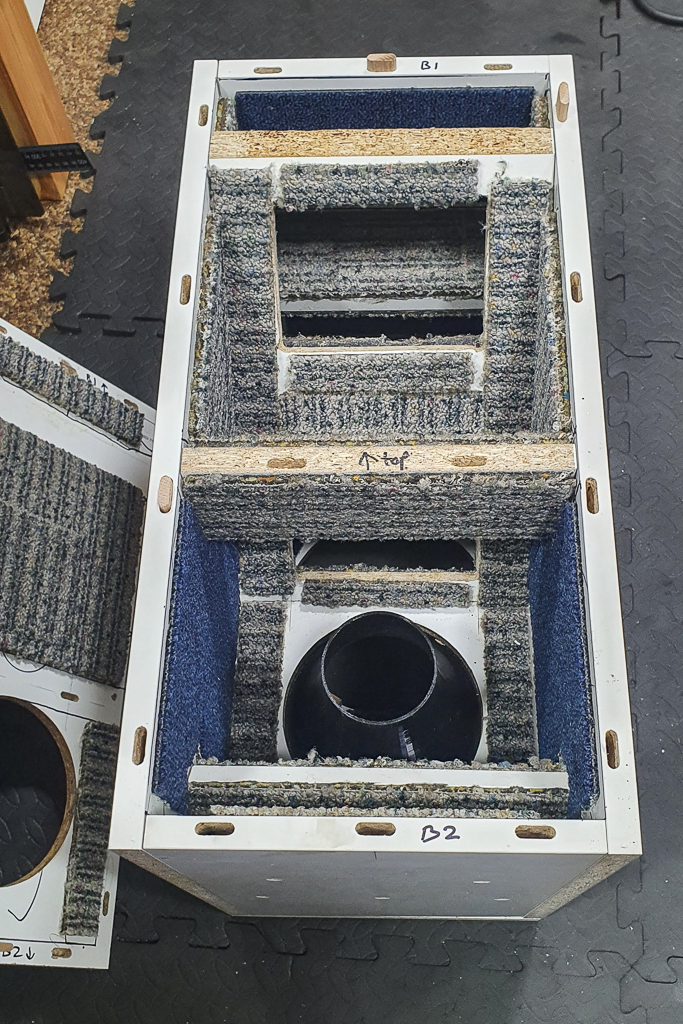

For reasons too longwinded to detail, I found myself needing to rebuild a pair of old floorstanding loudspeakers in what would be more of a bookshelf format. As this was during the depths of one of the Covid lockdowns, construction materials were in limited supply, so I decided to go "full Yorkshire" and see just how little money I could spend in doing the job.

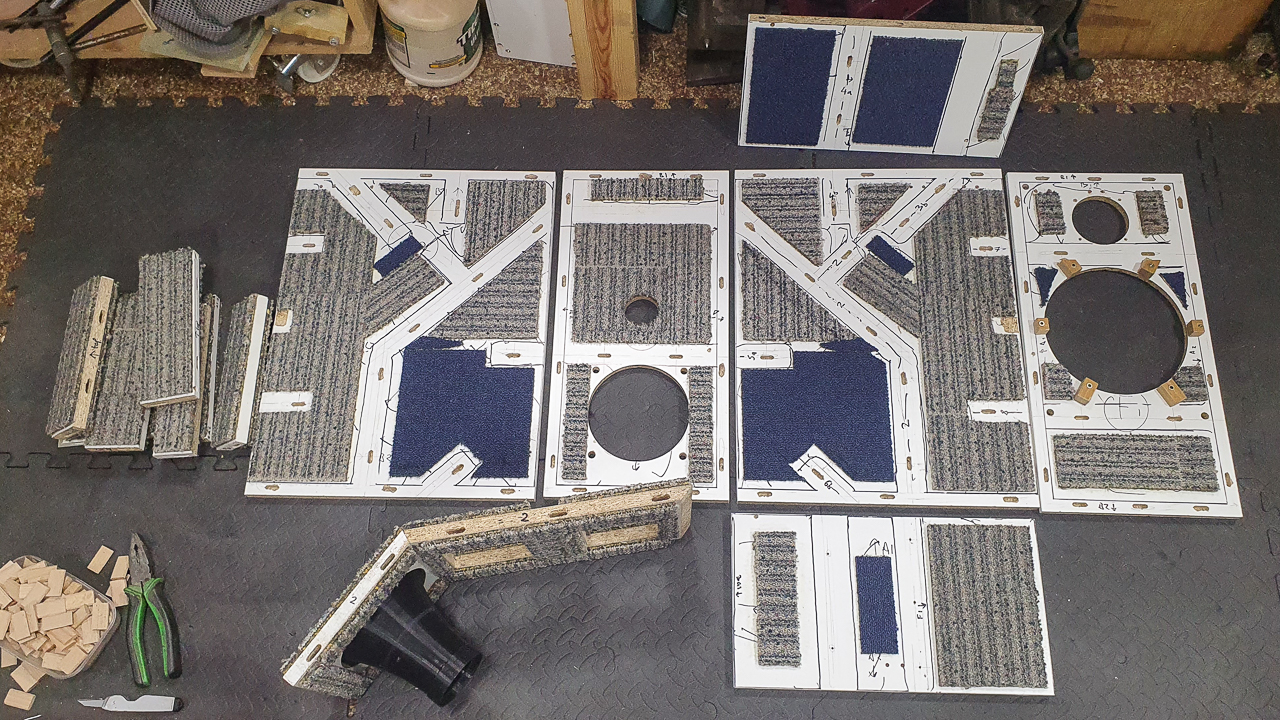

I had a bunch of surplus IKEA kitchen doors - 16mm chipboard covered in white laminate. Hardly ideal, but it was available, and free.

The original speakers (approx 255x255x900mm) were built from a design by Wilmslow Audio, and featured a ported enclosure with an 8" midbass and a treble. They've been great, but my main concerns were the lack of internal bracing with the enclosure design, and the fact the port tube was a straight piece of of 2.5" diameter pipe. That diameter was arguably a bit small for the design, and could lead to audible "chuffing" under high load.

Because I was going to use the same drivers and crossover, the front baffle width must remain unchanged, as must the driver placement and internal volume. The port tuning would also ideally match the original design.

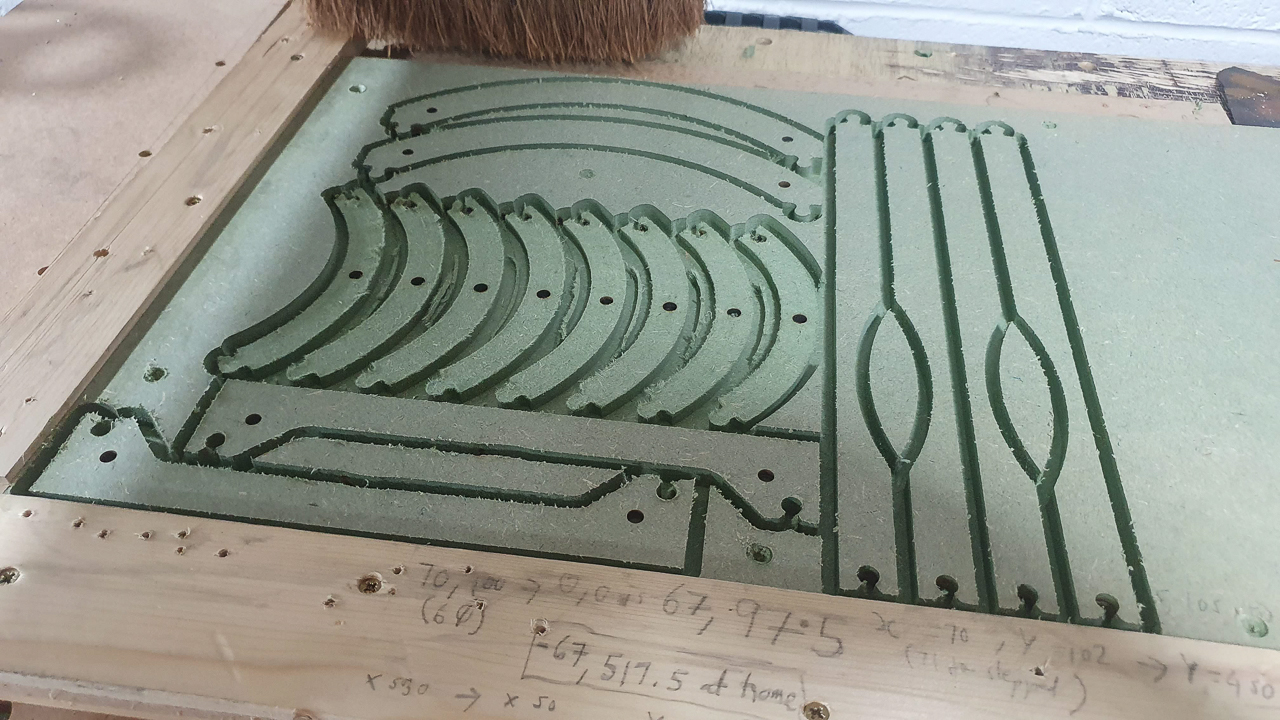

Based on https://jahonen.kapsi.fi/Audio/Papers/AES_PortPaper.pdf I came up with a "better" port design; incorporating the curves described in the paper. The move to a smaller cabinet height, combined with the larger diameter of the port, meant that the port had to be rear firing; rather than on the front face like the original floorstanders.

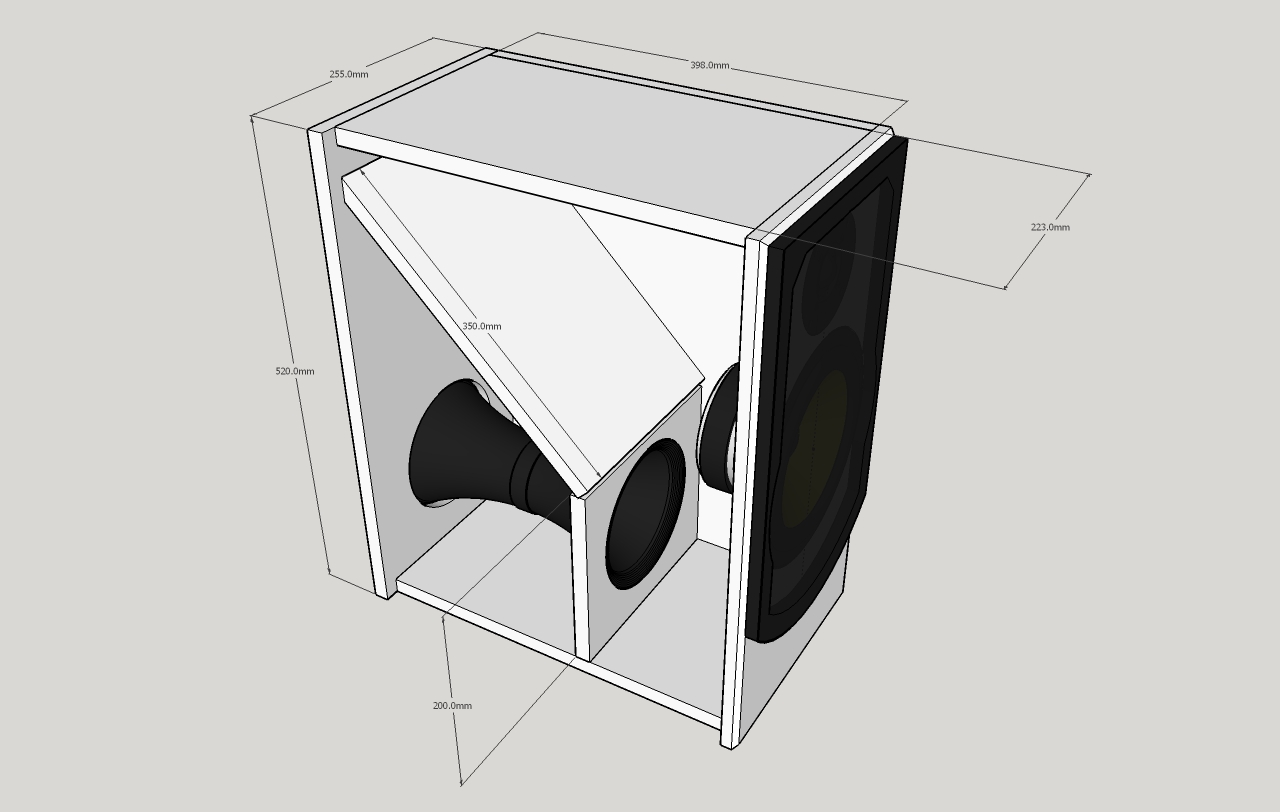

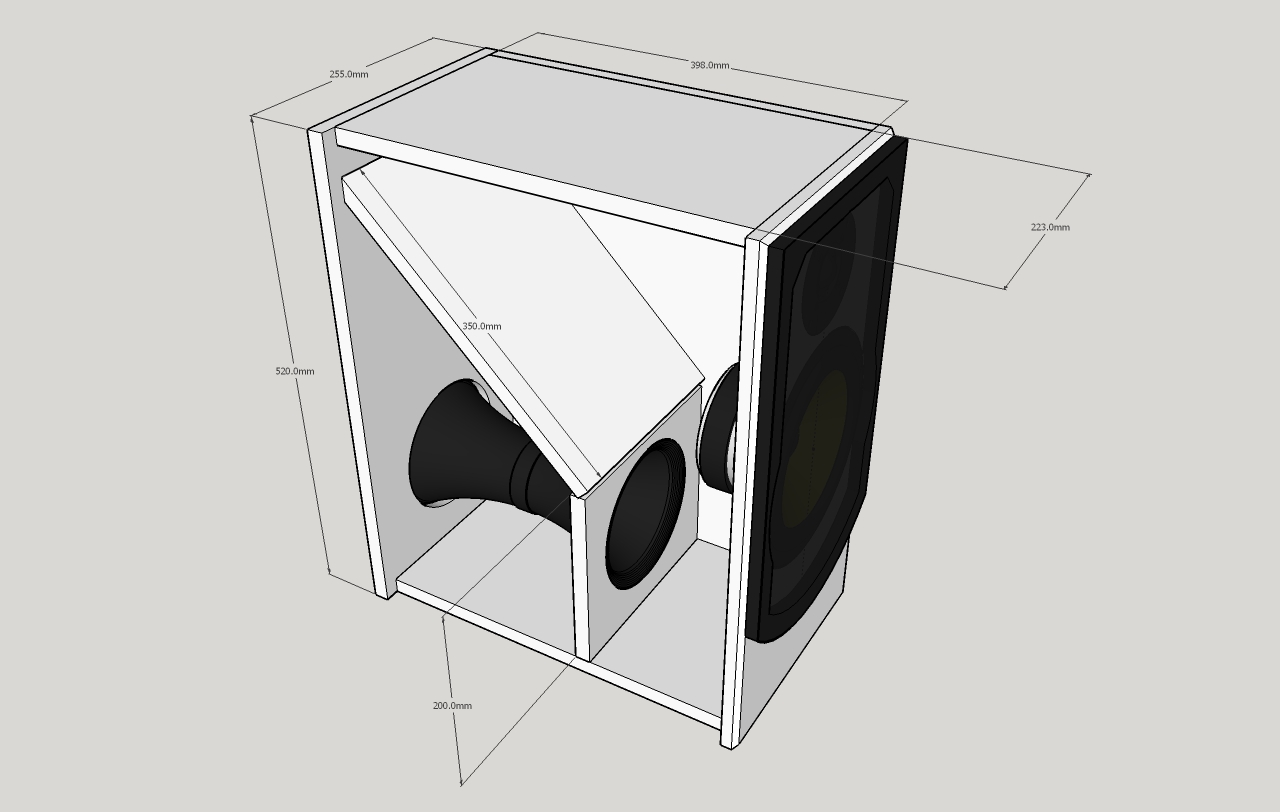

A quick prototype in SketchUp resulted in the following layout:

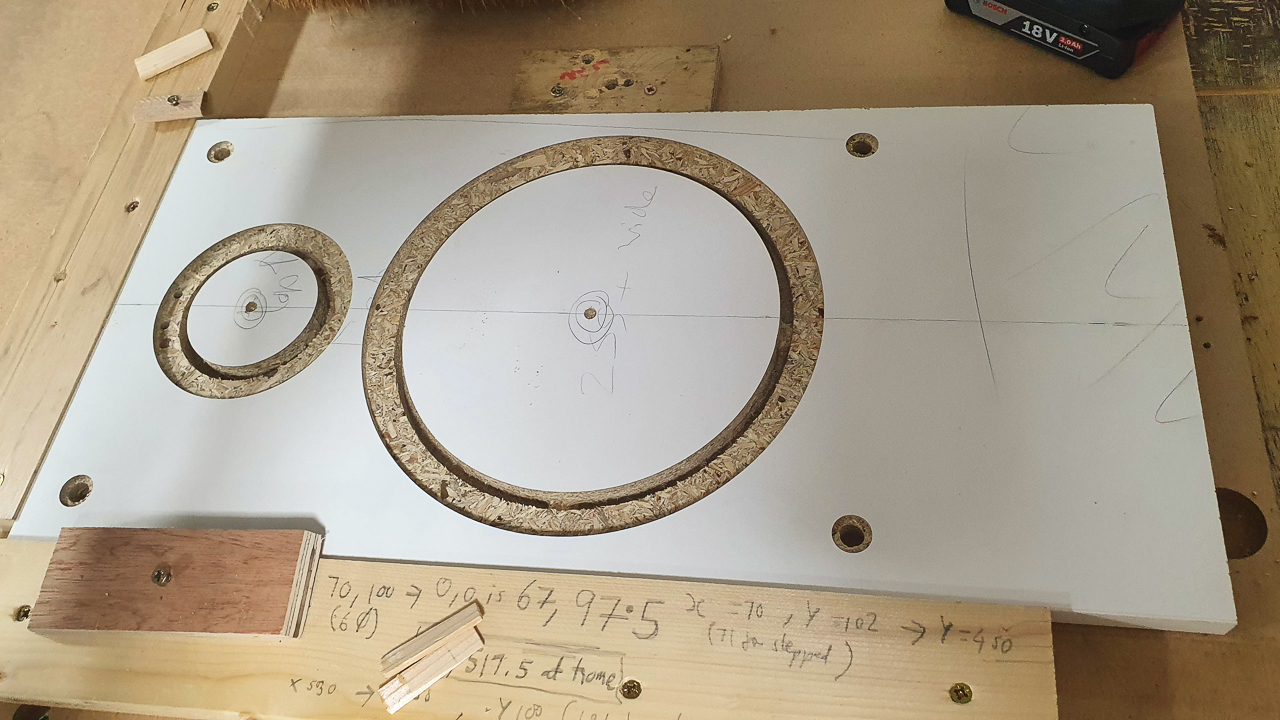

The ports were then 3D printed (in two parts, due to the size):

To be continued...

I had a bunch of surplus IKEA kitchen doors - 16mm chipboard covered in white laminate. Hardly ideal, but it was available, and free.

The original speakers (approx 255x255x900mm) were built from a design by Wilmslow Audio, and featured a ported enclosure with an 8" midbass and a treble. They've been great, but my main concerns were the lack of internal bracing with the enclosure design, and the fact the port tube was a straight piece of of 2.5" diameter pipe. That diameter was arguably a bit small for the design, and could lead to audible "chuffing" under high load.

Because I was going to use the same drivers and crossover, the front baffle width must remain unchanged, as must the driver placement and internal volume. The port tuning would also ideally match the original design.

Based on https://jahonen.kapsi.fi/Audio/Papers/AES_PortPaper.pdf I came up with a "better" port design; incorporating the curves described in the paper. The move to a smaller cabinet height, combined with the larger diameter of the port, meant that the port had to be rear firing; rather than on the front face like the original floorstanders.

A quick prototype in SketchUp resulted in the following layout:

The ports were then 3D printed (in two parts, due to the size):

To be continued...

![DSCF0727[1].JPG DSCF0727[1].JPG](https://cdn.imagearchive.com/ukworkshop/data/attachments/117/117075-0368007c4ff8062807efbc6698d770c0.jpg)