CNC Paul

Established Member

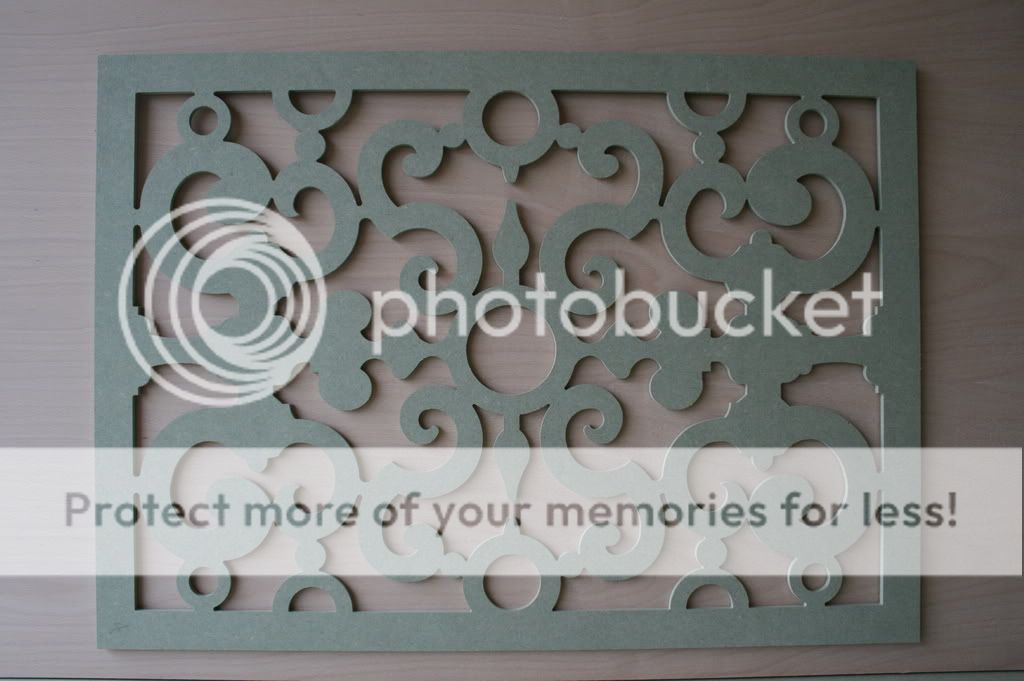

I am just starting a new project to make some solid oak

and some painted radiator casings, I have just prepared

the oak for the parts that need to be turned.

I will keep posting as things progress.

Paul

and some painted radiator casings, I have just prepared

the oak for the parts that need to be turned.

I will keep posting as things progress.

Paul