Ironballs

Established Member

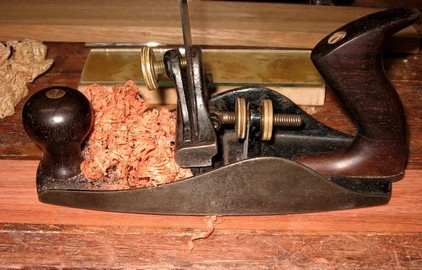

Used my my #112 pattern scraper plane in anger for the first time yesterday and have the blade sharpened to a bevel rather than hook/burr. Worked fine but it did leave some tracks on the surface of the wood, much like my smoother did before I curved the blade.

So the question is, do you other chaps use a straight blade but fettle your set up or do you put a curve in your blade? And by curve I mean take the corners off rather than bend the blade like a card scraper.

Cheers - Damian

So the question is, do you other chaps use a straight blade but fettle your set up or do you put a curve in your blade? And by curve I mean take the corners off rather than bend the blade like a card scraper.

Cheers - Damian