Chaps, I'm struggling making straight cuts on the bandsaw. Using the included metal mitre gauge that I'm very happy is at 90', when I feed a piece through, the blade wanders off line.

I will eventually make cross cut and mitre sleds but need to get my feeding technique right first. Here are some macro pics to illustrate.

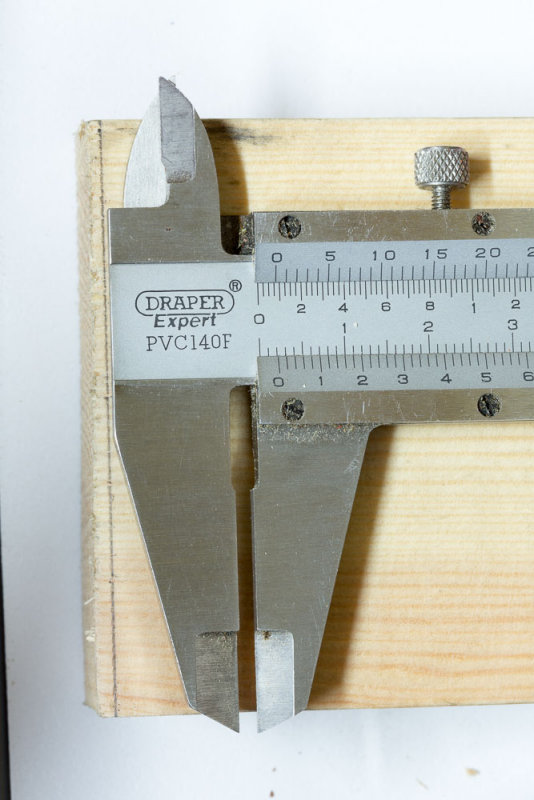

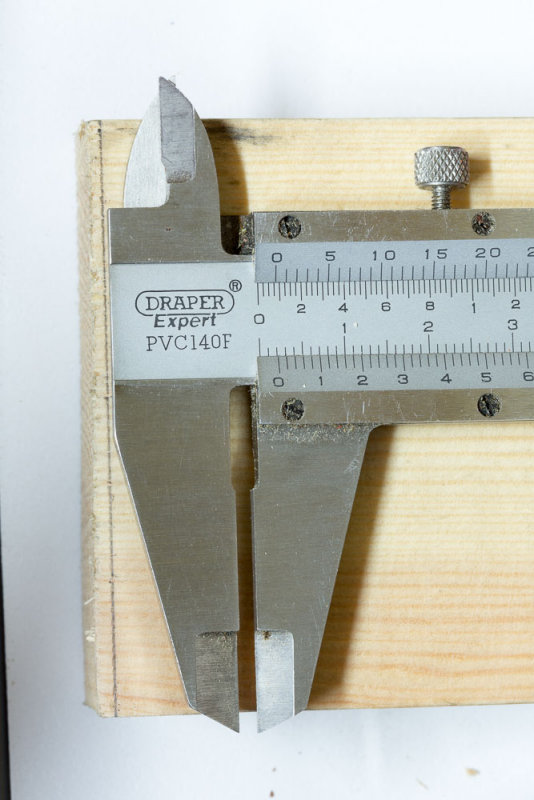

70mm wide piece of planed scrap. At the bottom the thickest part is 2mm from the pencil line

Obvious with a bright light behind

Blade is definitely vertical

However it's off side on (4tpi 1/2" blade BTW)

Yes these are extreme close ups of small variations but the inaccuracy is bugging me. What am I doing wrong? (hammer)

TIA

I will eventually make cross cut and mitre sleds but need to get my feeding technique right first. Here are some macro pics to illustrate.

70mm wide piece of planed scrap. At the bottom the thickest part is 2mm from the pencil line

Obvious with a bright light behind

Blade is definitely vertical

However it's off side on (4tpi 1/2" blade BTW)

Yes these are extreme close ups of small variations but the inaccuracy is bugging me. What am I doing wrong? (hammer)

TIA