MikeG.

Established Member

I'll come right out and say it........I dislike the English/ European bridge guards, and prefer the American swinging guard. Here's mine:

There are a number of factors in its favour, but there are also a couple of fundamental issues, and this is what I am hoping to address with a couple of modifications. Firstly, and it's not obvious from the photo, but the guard whacks the bottom edge of the fence, and over time, knocks it out of adjustment. I started getting some non-square edges during my long bout of machining of items for my staircase.

The other problem is this. The guard covers all the blade when the fence is over at the far extremity of the table. However, I am sure we all like to vary the location of the wear on the knives, so I obviously move the fence over, like this:

That little bit of exposed cutter block doesn't seem to be much of an issue, but actually, it can be where the machine can chuck chippings or even a bit of a knot out at you. I need something to make the swinging guard work for all fence locations. It also is something of an issue as the workpiece exits the cutter, but still holds the fence back:

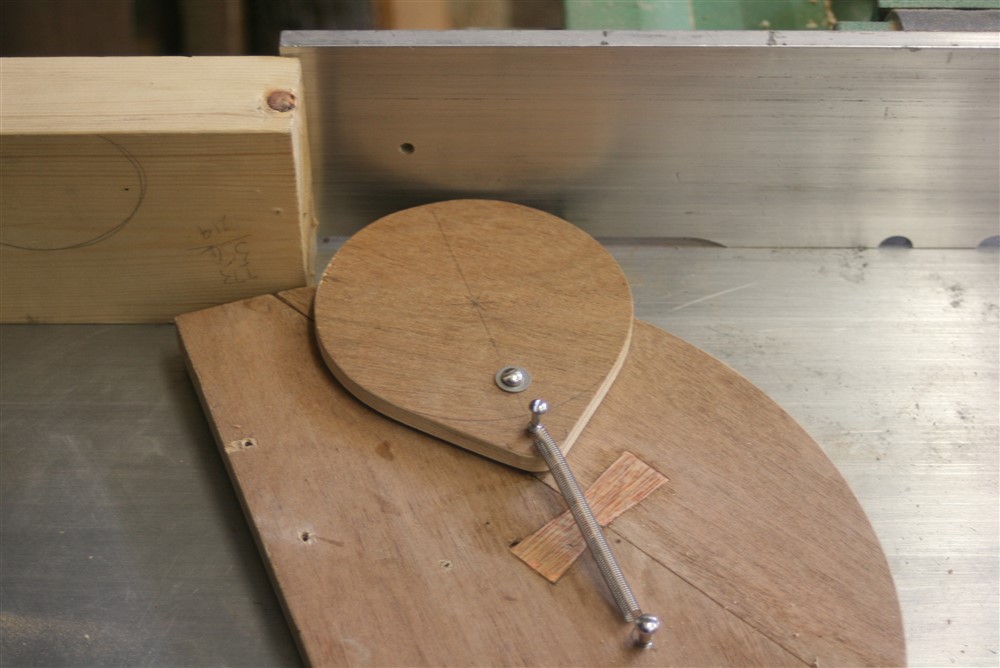

Let's tackle the difficult one first. I've had a few solutions in mind for a while, but the last few days has given me plenty of time to sit and ponder, and I settled on one:

I think this was the plastic foot of an old dog guard for the car (it might be rubber). You can see a before and after in the same photo:

Fixed in place this prevents the returning guard smacking into the fence. OK, when opened past about 6 inches it still touches it a bit, but its now well cushioned, and for most planing it doesn't touch it at all:

And here it is at the extreme setting, with the fence in the middle of the table:

Tomorrow, if I'm up to it, I'll fix the easier problem of the exposed blade which shows up really nicely in that last photo.

There are a number of factors in its favour, but there are also a couple of fundamental issues, and this is what I am hoping to address with a couple of modifications. Firstly, and it's not obvious from the photo, but the guard whacks the bottom edge of the fence, and over time, knocks it out of adjustment. I started getting some non-square edges during my long bout of machining of items for my staircase.

The other problem is this. The guard covers all the blade when the fence is over at the far extremity of the table. However, I am sure we all like to vary the location of the wear on the knives, so I obviously move the fence over, like this:

That little bit of exposed cutter block doesn't seem to be much of an issue, but actually, it can be where the machine can chuck chippings or even a bit of a knot out at you. I need something to make the swinging guard work for all fence locations. It also is something of an issue as the workpiece exits the cutter, but still holds the fence back:

Let's tackle the difficult one first. I've had a few solutions in mind for a while, but the last few days has given me plenty of time to sit and ponder, and I settled on one:

I think this was the plastic foot of an old dog guard for the car (it might be rubber). You can see a before and after in the same photo:

Fixed in place this prevents the returning guard smacking into the fence. OK, when opened past about 6 inches it still touches it a bit, but its now well cushioned, and for most planing it doesn't touch it at all:

And here it is at the extreme setting, with the fence in the middle of the table:

Tomorrow, if I'm up to it, I'll fix the easier problem of the exposed blade which shows up really nicely in that last photo.