Graaz0r

Established Member

I thought after much browsing of this site and admiration of all your fine works, I'd post my first picture frame, really my first project that isn't in some way house/DIY related.

Used beech for the frame and black walnut for the splines, not perfect but happy enough for a first attempt, hopefully next ones will be a little crisper. It'll have a canvass installed and the black plywood is just for mounting and a small shadow gap around the canvass.

Biggest learnings were...

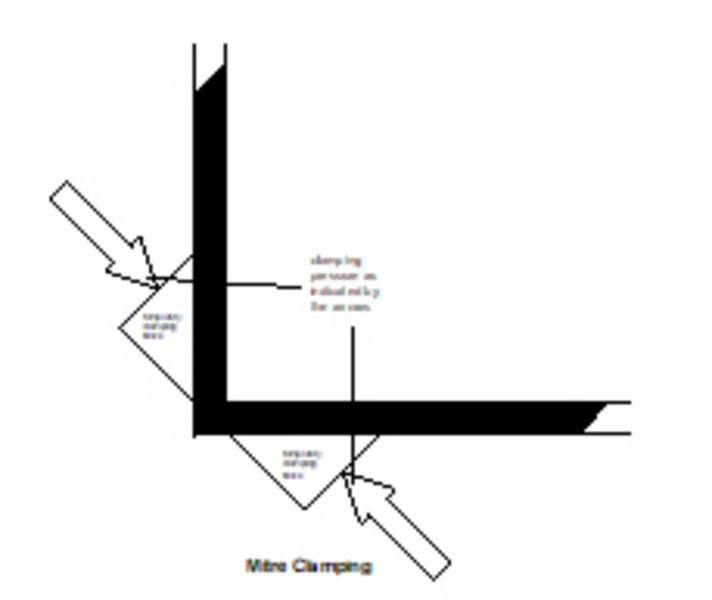

1) I clamped it like an ***** when I glued it up (clamp from end to end, will make some corner jigs before I make the next one)

2) I've since cut my riving knife to make non-through cuts to cut the rebate as a router (handheld) was a real pain !

3) Need some more practice on making the splines, didn't come out as crisp as I'd hoped

Not finished it with anything yet, that side is a little alien to me so need to do some reading, any advice/suggestions on what to use / how to use it is most welcome!

Used beech for the frame and black walnut for the splines, not perfect but happy enough for a first attempt, hopefully next ones will be a little crisper. It'll have a canvass installed and the black plywood is just for mounting and a small shadow gap around the canvass.

Biggest learnings were...

1) I clamped it like an ***** when I glued it up (clamp from end to end, will make some corner jigs before I make the next one)

2) I've since cut my riving knife to make non-through cuts to cut the rebate as a router (handheld) was a real pain !

3) Need some more practice on making the splines, didn't come out as crisp as I'd hoped

Not finished it with anything yet, that side is a little alien to me so need to do some reading, any advice/suggestions on what to use / how to use it is most welcome!