Stormer1940

Established Member

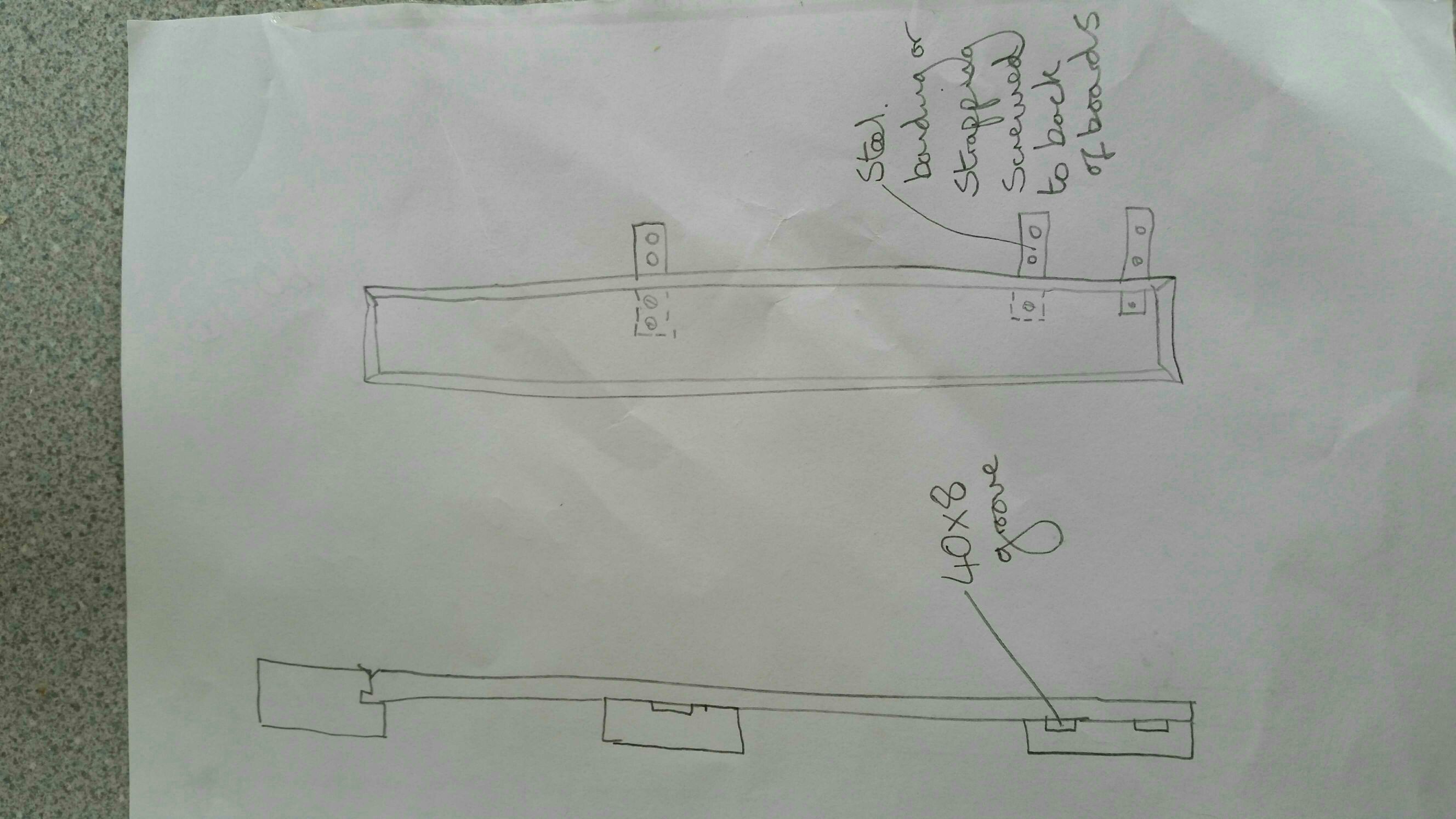

Hi looking to make a door like this from euro oak. Usually I'd groove the stiles and form a barefaced tongue to accommodate the matchboard at the sides and top rail but whats the best way to fix the matchboard to the rails across the door without nailing through the face?

Cheers

Cheers