Hi folks,

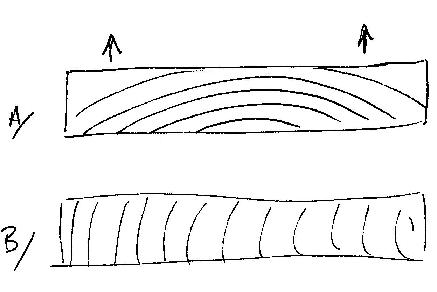

I've made a few signs using oak and in one instance the board has cupped badly and there are numerous splits running the length of the board. Here's the spec etc:

Signboard is approx four months old! European oak - 25mm thk x 200mm wide and 900mm long (grain running along the 900mm). Lengthy name v-carved in script typestyle along its length but taking up perhaps only 1/6 of the surface area as strokes are relatively narrow. Max depth of v-carve 8mm. Board has been finished using three coats danish oil.

Owner didn't want holes drilled through the board as he wanted to mount it by using 'L' brackets from behind onto posts.

My own suspicions are that:

1. Carving has released surface tension allowing the board to cup - should it have bracing on the back?

2. Sign is located close to the sea approx 100M away - perhaps salt air has dried the face more that the back?

3. Use of (flimsy) 'L' brackets are too weak to hold it firmly against posts which would otherwise afford it some barcing.

I have no problem with making a new one and I am using the experience positivly to help me understand the underlying cause so that I can save it happening in the future. I can try out possible solutions but it could take a long time before I would be able to determine if they are working or not, so I'm hoping somebody here will have prior experience of this. Any suggestions and experiences much appreciated.

Cheers - Neil

I've made a few signs using oak and in one instance the board has cupped badly and there are numerous splits running the length of the board. Here's the spec etc:

Signboard is approx four months old! European oak - 25mm thk x 200mm wide and 900mm long (grain running along the 900mm). Lengthy name v-carved in script typestyle along its length but taking up perhaps only 1/6 of the surface area as strokes are relatively narrow. Max depth of v-carve 8mm. Board has been finished using three coats danish oil.

Owner didn't want holes drilled through the board as he wanted to mount it by using 'L' brackets from behind onto posts.

My own suspicions are that:

1. Carving has released surface tension allowing the board to cup - should it have bracing on the back?

2. Sign is located close to the sea approx 100M away - perhaps salt air has dried the face more that the back?

3. Use of (flimsy) 'L' brackets are too weak to hold it firmly against posts which would otherwise afford it some barcing.

I have no problem with making a new one and I am using the experience positivly to help me understand the underlying cause so that I can save it happening in the future. I can try out possible solutions but it could take a long time before I would be able to determine if they are working or not, so I'm hoping somebody here will have prior experience of this. Any suggestions and experiences much appreciated.

Cheers - Neil