woodbloke

Established Member

Pete's (Newt) been over this afternoon for a natter and brought his 'Y' lever over for me to have a look at. It's been machined from a block of solid brass similar to the one in the pic and it took him about a day to do it. In our natterings we both agreed that there is far more thinking than doing time when you make something really complicated, as this is:

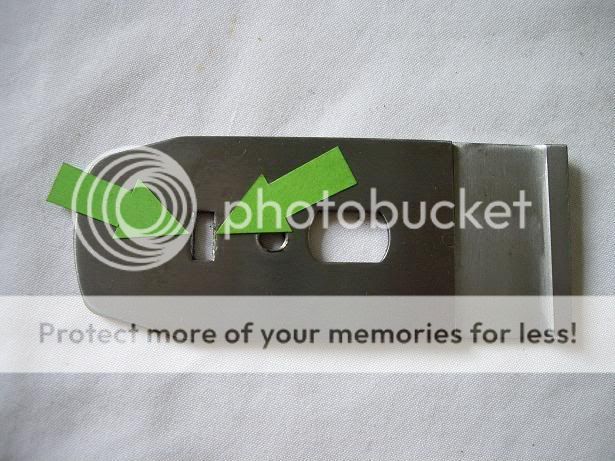

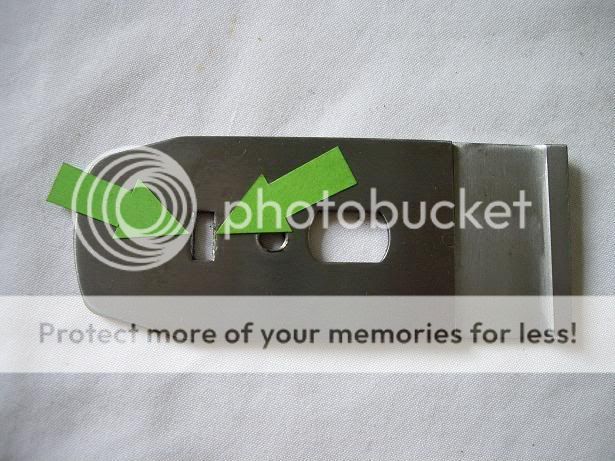

Pete also found that by relieving the back of the slot in the chipbreaker just a fraction by rounding over slightly with a needle file makes a very big difference in the ease wih which the blade can be retracted and moved forward....I found that a spot of grease on the bearing surfaces also helped a bit more:

The green arrows show the corner I'm on about, the pic shows the reverse side of a Clifton cap iron with the slight relieving having been done. We also had a natter about the merits of BU planes and I realized (and Pete was in firm agreement) the reason that they are so good is that the blade can be supported almost the the cutting edge by the bed, something that is impossible on a normal BD design.

Paul - your Record No4 already has this little cap iron mod done -Rob

Pete also found that by relieving the back of the slot in the chipbreaker just a fraction by rounding over slightly with a needle file makes a very big difference in the ease wih which the blade can be retracted and moved forward....I found that a spot of grease on the bearing surfaces also helped a bit more:

The green arrows show the corner I'm on about, the pic shows the reverse side of a Clifton cap iron with the slight relieving having been done. We also had a natter about the merits of BU planes and I realized (and Pete was in firm agreement) the reason that they are so good is that the blade can be supported almost the the cutting edge by the bed, something that is impossible on a normal BD design.

Paul - your Record No4 already has this little cap iron mod done -Rob