big

Member

Hi there!

I'm a bit new to all this sort of thing, or at least to the wonderful world of power tools and accuracy, but would like some advice on cutting a laminate (sorry!) kitchen worktop...

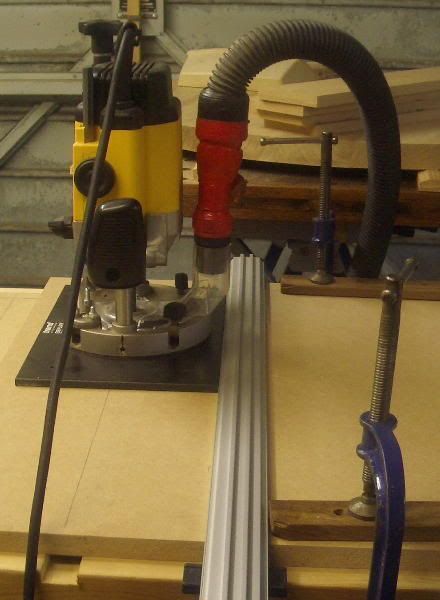

Firstly, I have a router with straight cut bits and have been attempting to get a lovely smooth cut widthways on the laminate. Using the parallel guide gave me a reasonable finish, but it stops me cutting any further than about 6" from the end (because of the guide), and occasionally the bit seemed to catch which left a small indentation on the inside of the cut (which I didn't really want..).

Then I attempted to cut a longer bit off, so I square-clamped a bit of batten as a stop guide for the router. This caused it to catch and make even deeper indentations..

So, how do I stop it catching?

And would I be better off making some sort of jig with 2 bits of batten, or perhaps skirting, clamped across the worktop?

Any answers and tips greatly appreciated - but I don't really want to buy anything expensive as it's probably the only time I'll do this job (famous last words..)

I'm a bit new to all this sort of thing, or at least to the wonderful world of power tools and accuracy, but would like some advice on cutting a laminate (sorry!) kitchen worktop...

Firstly, I have a router with straight cut bits and have been attempting to get a lovely smooth cut widthways on the laminate. Using the parallel guide gave me a reasonable finish, but it stops me cutting any further than about 6" from the end (because of the guide), and occasionally the bit seemed to catch which left a small indentation on the inside of the cut (which I didn't really want..).

Then I attempted to cut a longer bit off, so I square-clamped a bit of batten as a stop guide for the router. This caused it to catch and make even deeper indentations..

So, how do I stop it catching?

And would I be better off making some sort of jig with 2 bits of batten, or perhaps skirting, clamped across the worktop?

Any answers and tips greatly appreciated - but I don't really want to buy anything expensive as it's probably the only time I'll do this job (famous last words..)