jimi43

Established Member

Hi Guys and Gals...

I just won a new toy on FleaBay today and the missus picked it up for me....

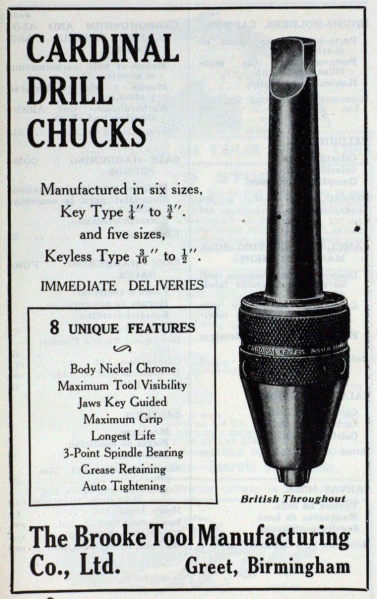

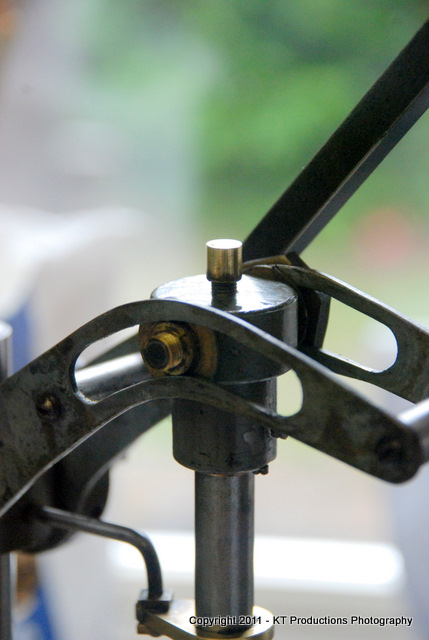

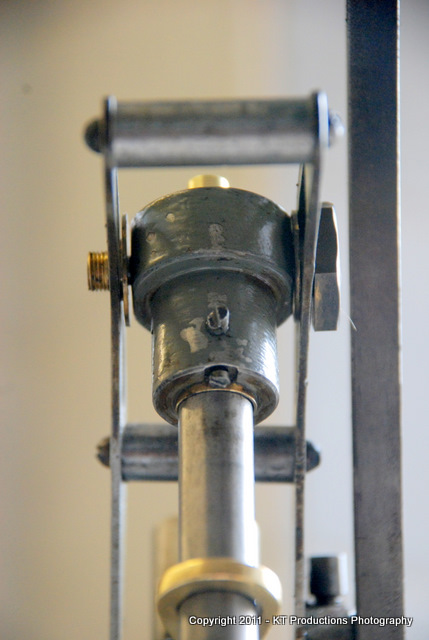

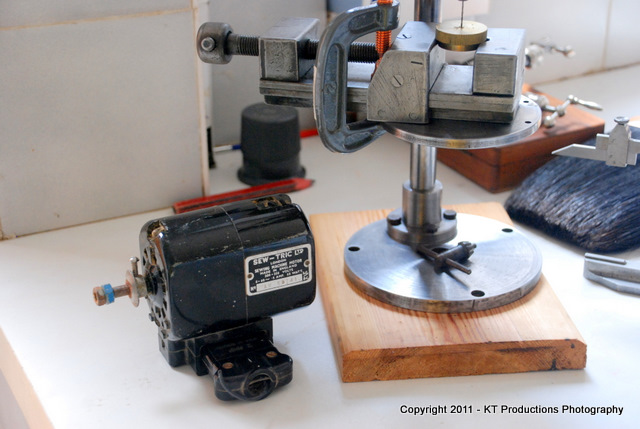

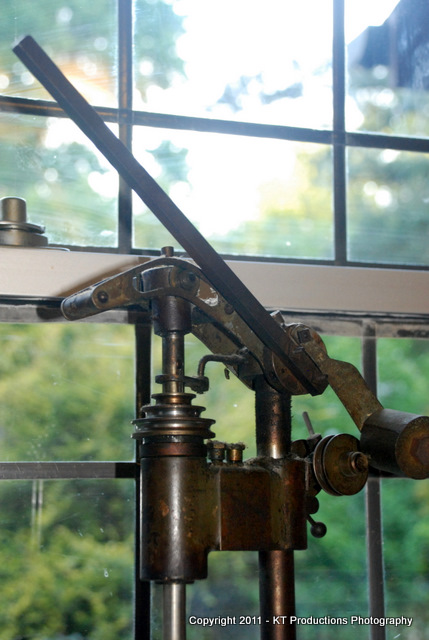

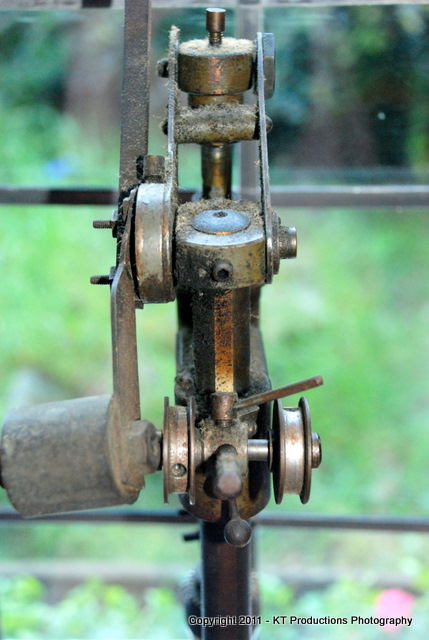

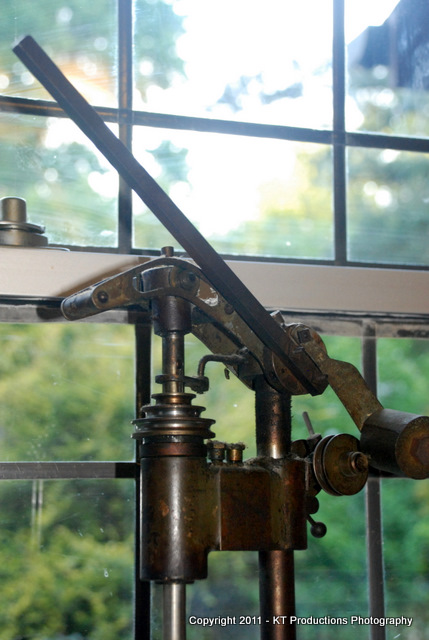

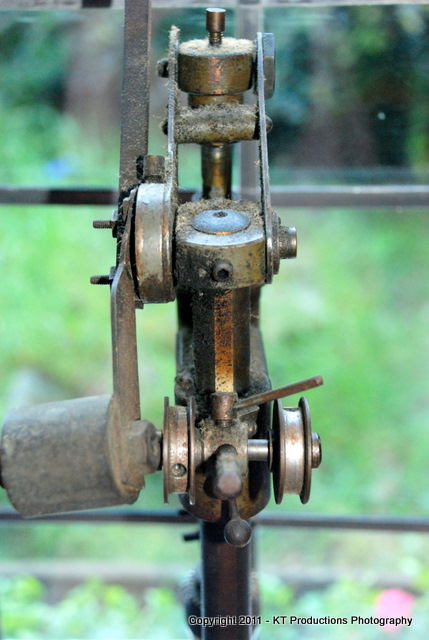

Can anyone help with identification? It looks like a Champion No.1 but there are no maker's marks anywhere apart from the chuck which has quite old script and is marked "ROTAX"

It really is a beautiful piece of engineering....it needs a bit of a clean/restoration....

...but it has so many gizmos and twiddly things on it that I think this will be real fun...just what I need to keep my mind occupied for the next few weeks....

...there are a few bent bits...

.....but it appears to be all there...

Any help would be most appreciated and I promise to document the whole restoration as I go along!

Cheers

Jimi

I just won a new toy on FleaBay today and the missus picked it up for me....

Can anyone help with identification? It looks like a Champion No.1 but there are no maker's marks anywhere apart from the chuck which has quite old script and is marked "ROTAX"

It really is a beautiful piece of engineering....it needs a bit of a clean/restoration....

...but it has so many gizmos and twiddly things on it that I think this will be real fun...just what I need to keep my mind occupied for the next few weeks....

...there are a few bent bits...

.....but it appears to be all there...

Any help would be most appreciated and I promise to document the whole restoration as I go along!

Cheers

Jimi