devonwoody

Established Member

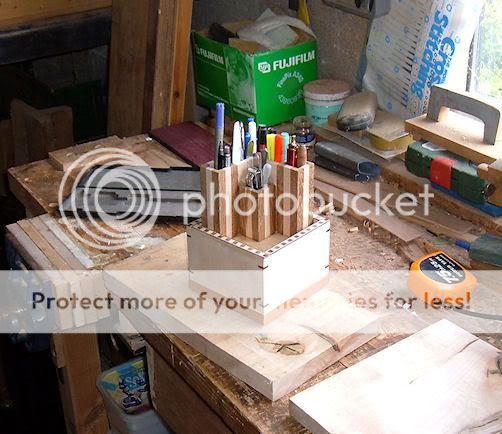

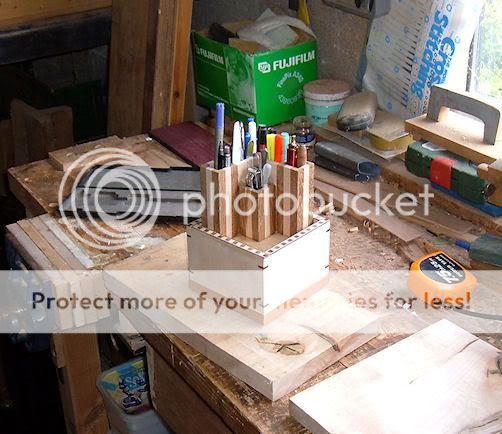

I have lost ten of my boxes this summer to friends and relatives including the pen box.

So started a new pen tidy.

Picture of the first pen tidy to copy, and it isn't easy copying, my brain doesn't seem to function to the project of whats needed, only copying and not forward thinking.

So started stripping :wink:

and the first operation was not a success, so making another batch as per pic below.

Lots of clamps and masking tape holding things in place.

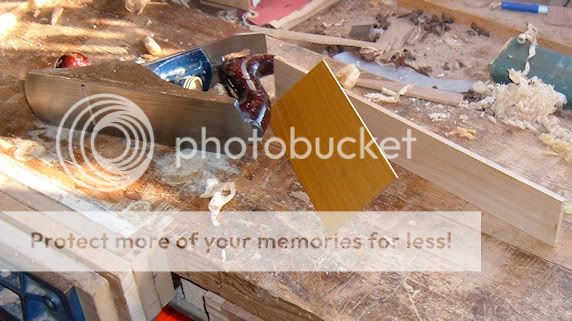

Handy offcuts, and one offcut is less than 0.4 thickness.

One successful section glued up. (american ash and black walnut.)

So started a new pen tidy.

Picture of the first pen tidy to copy, and it isn't easy copying, my brain doesn't seem to function to the project of whats needed, only copying and not forward thinking.

So started stripping :wink:

and the first operation was not a success, so making another batch as per pic below.

Lots of clamps and masking tape holding things in place.

Handy offcuts, and one offcut is less than 0.4 thickness.

One successful section glued up. (american ash and black walnut.)