Top guide:

Change sides of the adjustment screws, not difficult

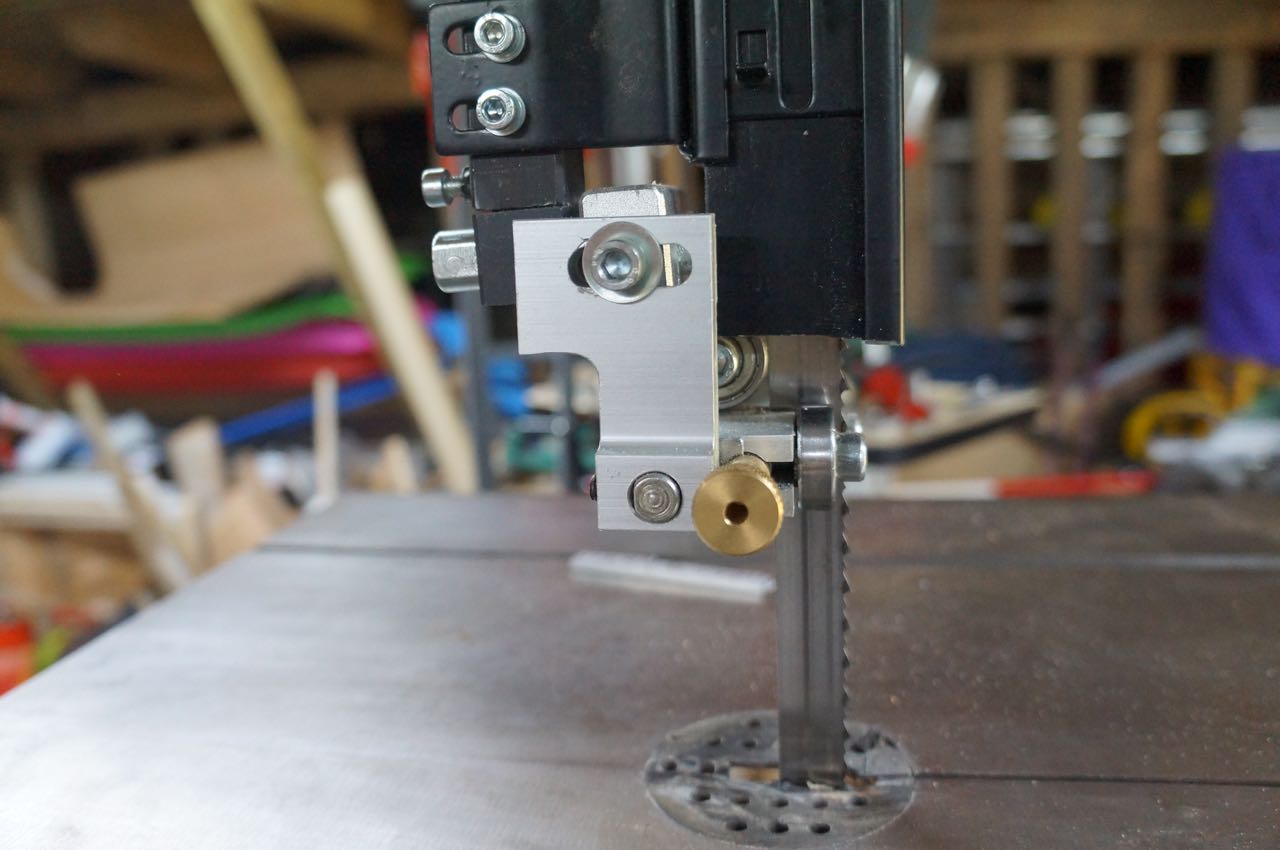

Make an attachment block, reamed to fit the Record Bar, width specific to ensure alignment, drill and tap both ends to accept vertical plate on the Axminster top guide and locating bolt to the bar, accuracy of this block is critical as it dictates the rear bearing location, lots of fit, try, take off modify and trial fit again.

Increase rear bearing guide travel.

Bottom guide:

Take off locating plate, not difficult.

Grind/file off the side of the guide block at 45degs to allow table tilt, you can see this in the picture above, time consuming.

Take off table to allow accurate drilling of the Bandsaw casing to accept fixing bolts, critical as this dictates the rear bearing position on the blade, fixing holes in the bearing block are blind so accuracy is needed, using the original locating plate helps.

Increase rear bearing guide travel.

Fit raising blocks to prevent front bearings lower edge fouling the casing, I used stud extending nuts to raise the guide as much as possible, so the distance between the top and bottom guides above and below the table is minimal.

In all I suppose it took me a full day to do this, whereas I think there must be an easier fix, I know about the Yandles top guide, its what I took off to do this modification.

Mike