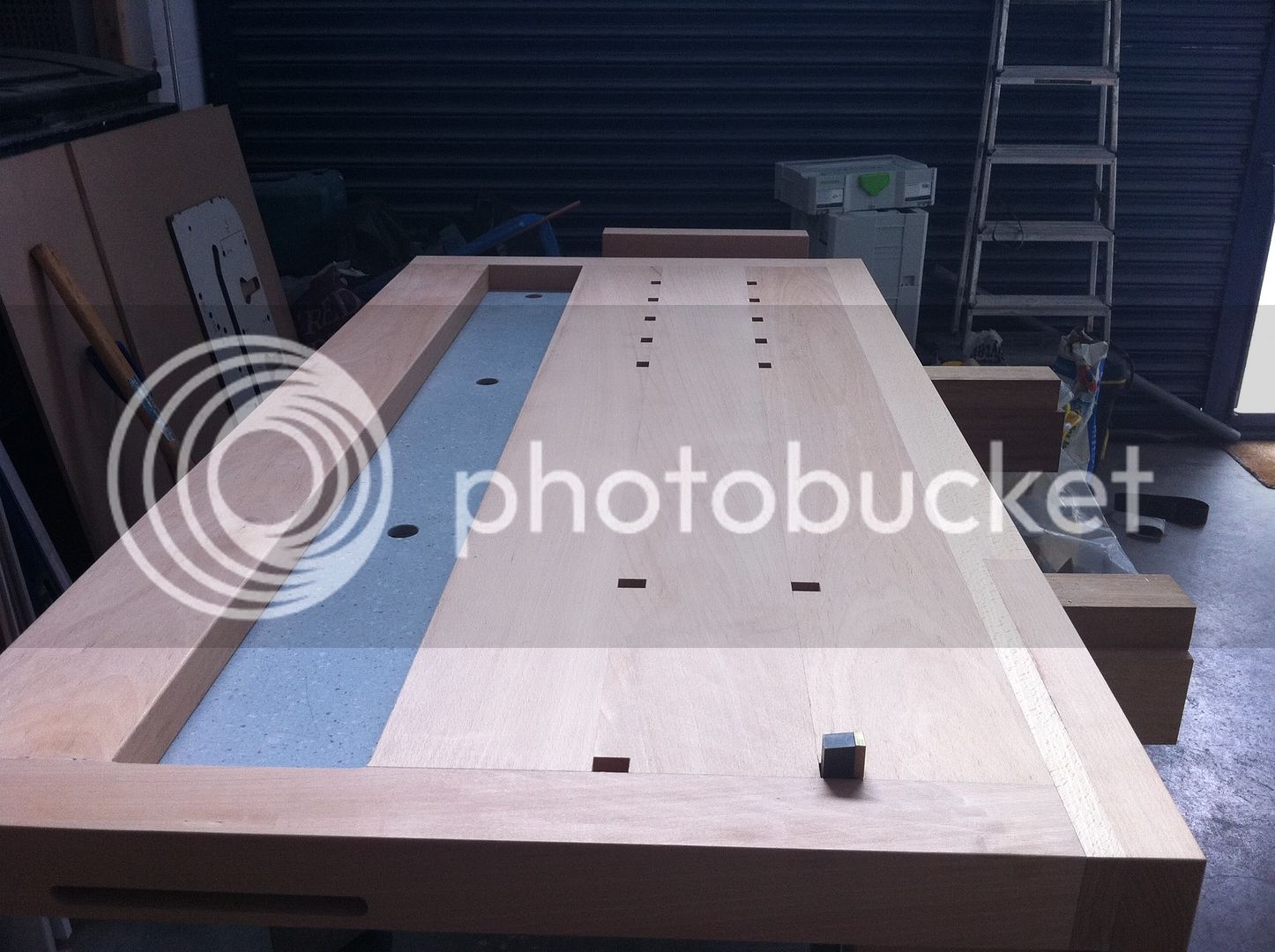

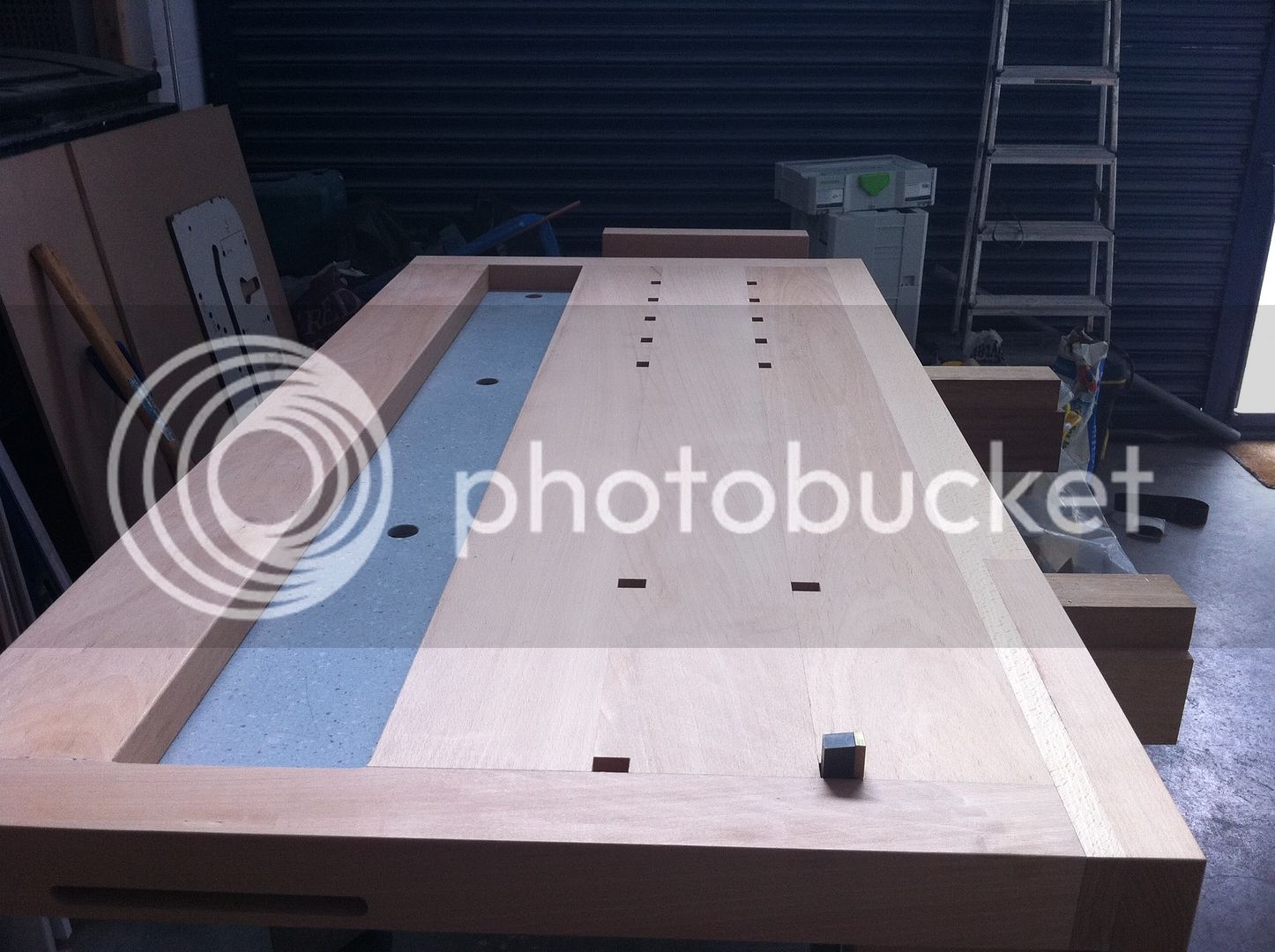

Hi, I would like to share with you some pictures of my first major project, a workbench, so I can work on learning furniture making. I have based the design on the David Charlesworth style, with removeable tool tray, although mine is made of Corian, leftover from a job. ( I run a construction business www.getturner.co.uk is our site)

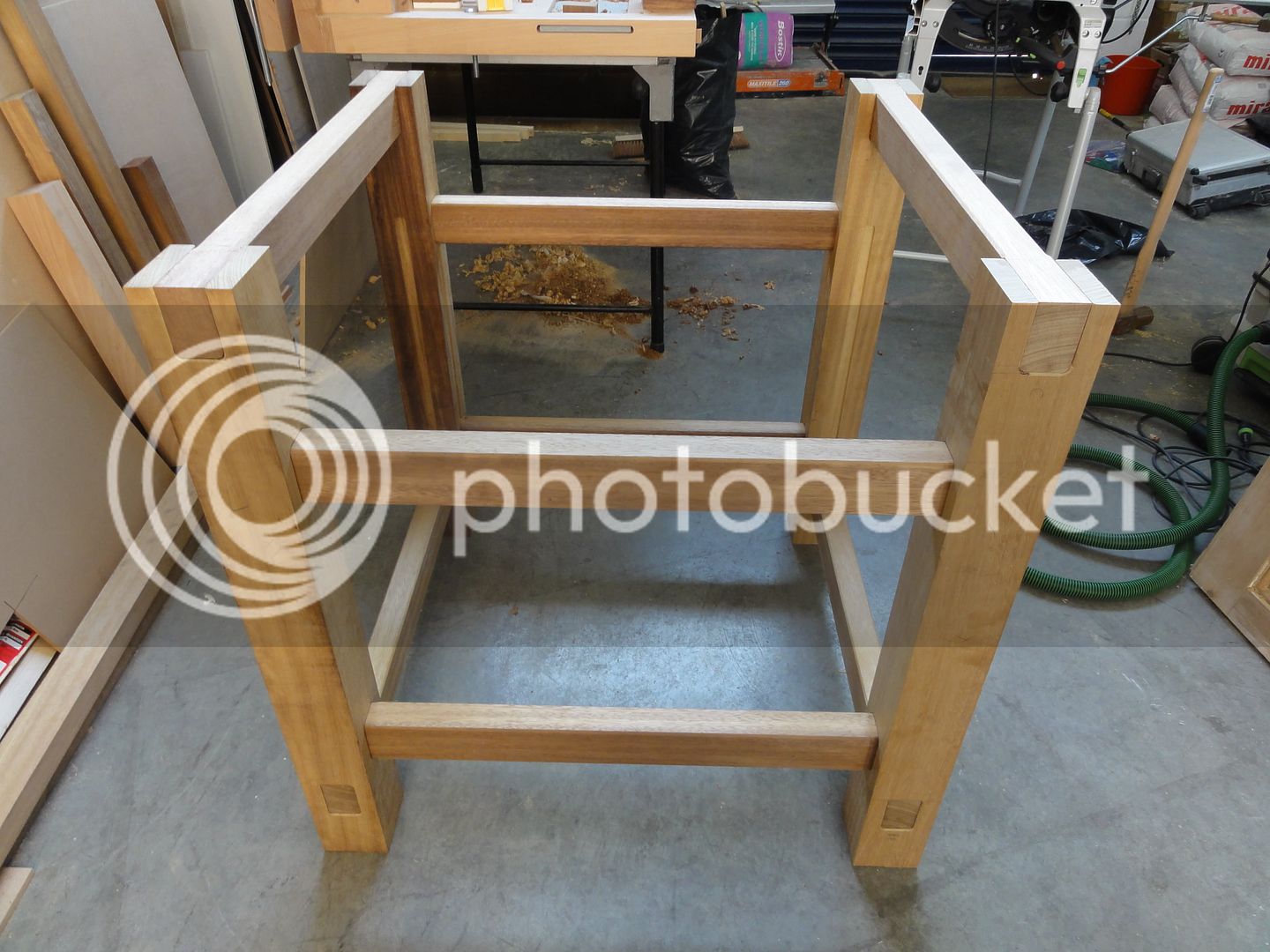

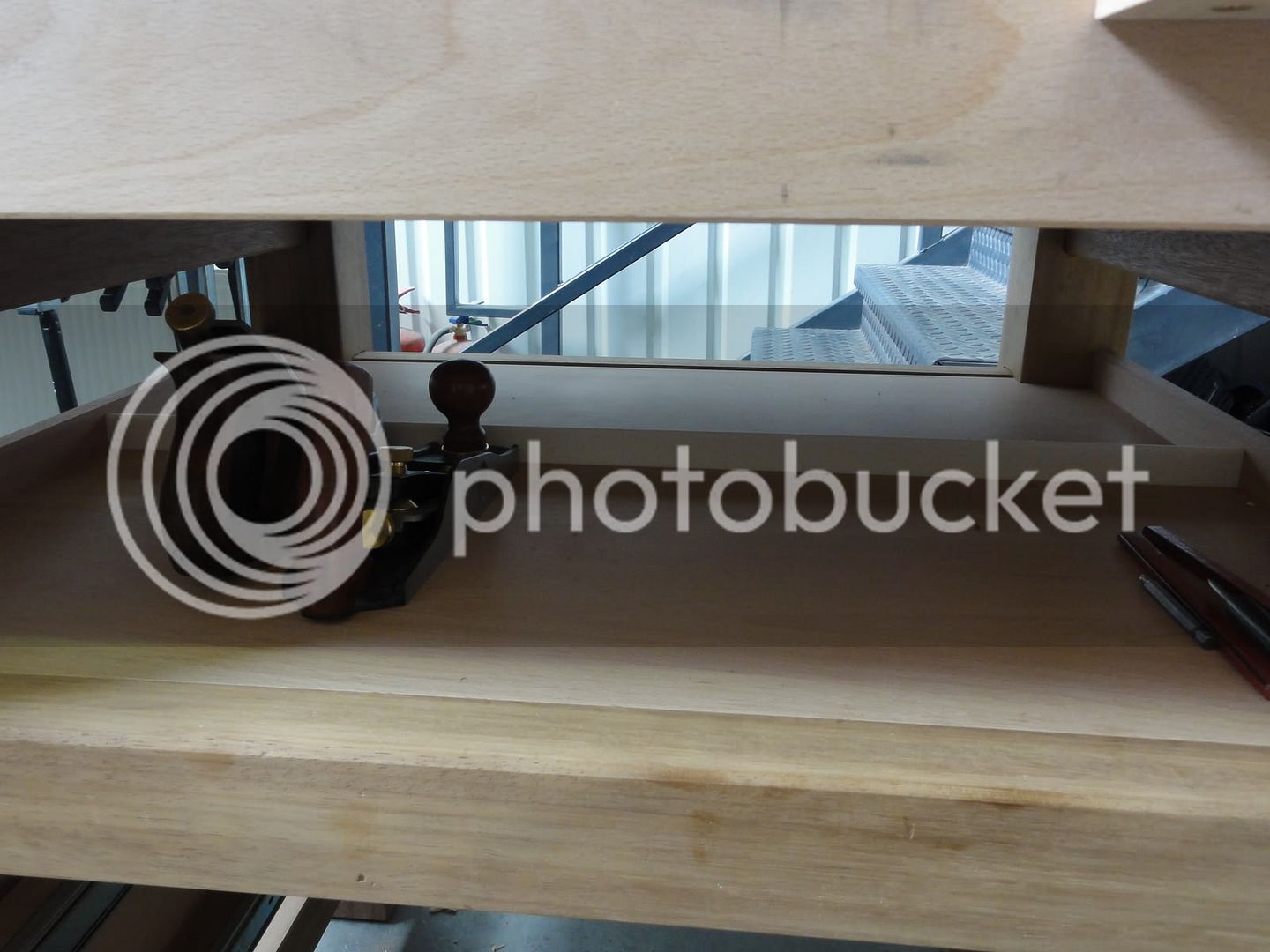

The top is from steamed beech 3 inch thick. I am going to make the frame from iroko, and it will have 2 drawers under in between the legs, with a space above to give clamp access and to store stuff on out of the way while working.

Comments and questions welcome

Cheers, Mark

The top is from steamed beech 3 inch thick. I am going to make the frame from iroko, and it will have 2 drawers under in between the legs, with a space above to give clamp access and to store stuff on out of the way while working.

Comments and questions welcome

Cheers, Mark