Well I'm back with James Mursell again. There are 5 of us on this course rather than the 2 I'm used to, but 'm really looking forward to this week.

I'll keep you posted on progress and will try not to repeat too much of my earlier posts. I hope you'll find something interesting in the next few days.

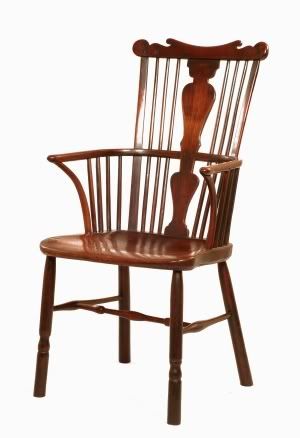

Here's the chair I'm making...

It's slightly different to the one at the top of this thread - note the crinoline stretcher. I'm also going to make the back legs similar to the front.

I say

similar not the

same for good reason. James sent me a leg to copy some months ago. My turning isn't great, so I've made 7 ( plus the pattern) - hopefully I'll find 4 that are a good match :wink:

Specification:-

- Elm seat (20" by 17 1/2").

Turned legs of green sweet chestnut.

Crinoline stretcher of steamed green ash connected to legs by stub stretchers turned from green oak.

The back will have a central splat of seasoned cherry, flanked on each side by 3 hand shaved oak spindles and a lath.

The arm bow is supported on each side by 4 short oak spindles and a steam-bent green ash arm bow.

The whole back is finished off with a steam-bent crest.

Not sure how I'm going to fill the empty hours over the next 5 days :shock:

Day 1

We started by steam bending the crinoline stretcher and the arm posts. James has prepared the arm bow for us - there's just too much to do otherwise. Anyway, I'm told the real skill in chair making comes at the assembly stage 8)

You can see the steam box on the left ot the picture above.

These arms posts are made as one and sawn apart later.

Day 1 - post coffee

Well it's back to spindle making - 6 long and 8 short today. I've decided on a different approach this time. Previously I've made a spindle from start to finish - employing the drawknife and various spokeshaves - before moving on to the next one. Today I shaped all 14 spindles with each tool before moving on to the next. I figure I'll be better at handling each tool and produce a result where the differences are fewer. Well that's the theory anyway :wink:

Here are the clefts green oak blanks.

I'm done with the drawknife ... and ready for the spokeshaves and dowel plate. I'ts clear that a bit of confidence with the coarse tools saves a mass of time.

This took most of the day - but I did have time to turn the stub stretchers, mark out the central splat and layout the sightlines for drilling the seat blank. Here's the underside...

Time for a beer.

Day 1 - addendum

Ok, I know some of you are groaning.

Same old views - nothing new here. Well how about....

Bending a crest. Now even James admits this hydraulic device he had custom built is a little over-engineered.

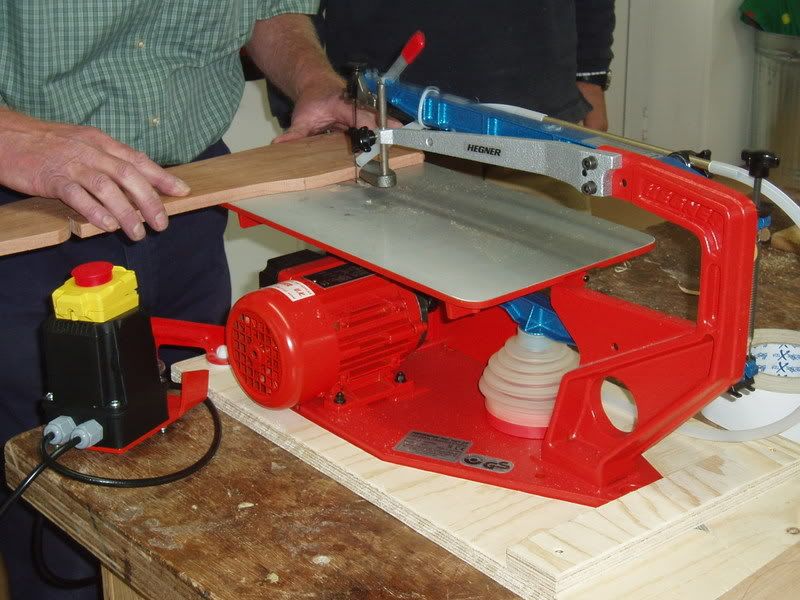

...and one for the scrollers - I have to get to grips with this beastie tomorrow to cut the central splat.

/.

/.