rileytoolworks

Established Member

Evening all.

I've not been turning long (turned a few mallets, dibbers and a pen), but tonight I thought I'd try to do a bowl.

I don't have a load of tools, so used a 3/8" spindle gouge for most of it (except roughing the outside), and my lathe is a record dm24 something or other. (My biggest gripe is having to use spanners to adjust EVERYTHING).

Anyhow, I digress.

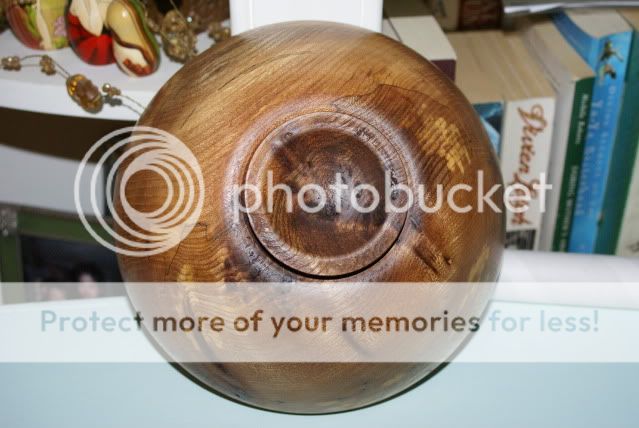

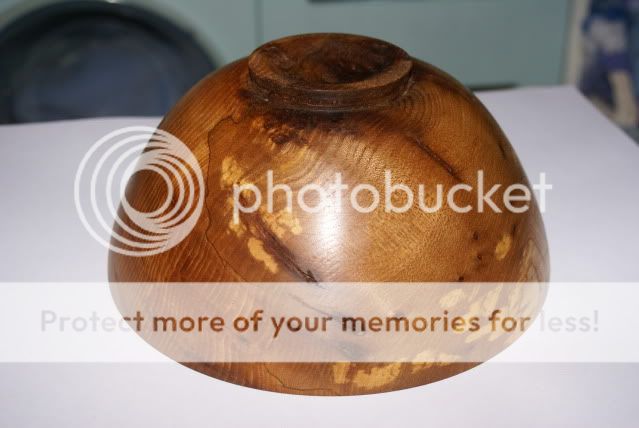

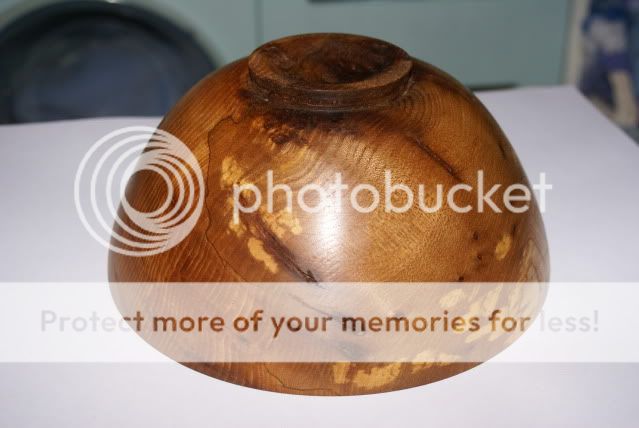

Here are some pictures. Please be kind...

Sorry about the photo's, I just took a few quick snaps.

As you can see, there's a fair bit of tearout on the inside, but I just wanted to get a finish on it and see what it looked like. I suspect everyone is the same on their first go.

Cheers.

Adam.

I've not been turning long (turned a few mallets, dibbers and a pen), but tonight I thought I'd try to do a bowl.

I don't have a load of tools, so used a 3/8" spindle gouge for most of it (except roughing the outside), and my lathe is a record dm24 something or other. (My biggest gripe is having to use spanners to adjust EVERYTHING).

Anyhow, I digress.

Here are some pictures. Please be kind...

Sorry about the photo's, I just took a few quick snaps.

As you can see, there's a fair bit of tearout on the inside, but I just wanted to get a finish on it and see what it looked like. I suspect everyone is the same on their first go.

Cheers.

Adam.