You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mitre T slot/track

- Thread starter OldWood

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

TheTiddles

Established Member

Firstly there's the obvious...

-Straight, this is all process related, and you might have to run a good few hundred metres to get it, along with associated cooling times

-Surface finish, needs to be good to get the plating to stick

-Plating, extrusion grade aluminium is normally very soft, you'll need a hard coating to stop is gouging, probably not in the price per metre

There's a whole load else that can go wrong on these processes. I know it always looks like a lot for what it is, but the cost is there to cover the fact that it's not as easy as it appears!

Aidan

-Straight, this is all process related, and you might have to run a good few hundred metres to get it, along with associated cooling times

-Surface finish, needs to be good to get the plating to stick

-Plating, extrusion grade aluminium is normally very soft, you'll need a hard coating to stop is gouging, probably not in the price per metre

There's a whole load else that can go wrong on these processes. I know it always looks like a lot for what it is, but the cost is there to cover the fact that it's not as easy as it appears!

Aidan

During my apprenticeship I worked on a number of extrusion dies and saw them in use, and as Aidan states, getting it sorted and running can be long and complex. The men on the plant were either playing cards or working flat out, as once sorted you didn't dare stop it!

Roy.

Roy.

wills-mill

Established Member

Could it not be CNC routed from solid for less hassle in what seems to be a relatively 'small' batch?

TheTiddles

Established Member

I think the cheapest way to get some T-track would be to buy it! A bulk order from the USA probably being cheaper even with import duty.

The only way I could think of making it for cheap, which wouldn't be as good as aluminium, would be to rout a slot in your MDF or whatever, insert a plastic strip like acetal and then rout the T-slot into that, may be a bit cheaper than T-track but I'd still pay the extra to avoid the faff.

Aidan

The only way I could think of making it for cheap, which wouldn't be as good as aluminium, would be to rout a slot in your MDF or whatever, insert a plastic strip like acetal and then rout the T-slot into that, may be a bit cheaper than T-track but I'd still pay the extra to avoid the faff.

Aidan

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£20.16

£26.00

Restore: The instant Sunday Times bestseller from the Repair Shop’s woodworking expert

Amazon.co.uk

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

rafezetter

Troll Hunter

Hi - new to site - registered to post this...

Saw this thread, as I've spent hours searching and racking my brain to think of a cheaper solution than the costs rutlands charge, and wondered if anything came of it?

I'm willing to pony up the dough to pay for a bulk buy if enough people are interested and I saw these which look good - the track is standard 3/4" but the complementary insert bar looks good too - with a space underneath for a bolt head or nut or whatever, bit of epoxy glue and it should be fine.

5th one down: (m l c s woodworking . com - miter_t-slot_accessories) - (highlight and google it using those words as I cant post links )

My other idea was to buy some UHMW strips and route them to the same profile as the inserts - although I'd have to finish making my router table first! chicken and egg almost - then add bolts, nuts whatever to the underside (drill a slightly smaller hole and bang it in flush), that way you can add whatever bolt / nut size you prefer.

Alternatively I found an american company that does the same slider kit from rutlands, but much cheaper; $6.95 a pair - I priced 3 pairs with postage to £19!! a price rutlands won't match even if you buy 15 or more sets - so again a bulk buy would work out well.

Let me know here if you are interested in a bulk buy, or would help with the UHMW idea if you think it has merit.

Saw this thread, as I've spent hours searching and racking my brain to think of a cheaper solution than the costs rutlands charge, and wondered if anything came of it?

I'm willing to pony up the dough to pay for a bulk buy if enough people are interested and I saw these which look good - the track is standard 3/4" but the complementary insert bar looks good too - with a space underneath for a bolt head or nut or whatever, bit of epoxy glue and it should be fine.

5th one down: (m l c s woodworking . com - miter_t-slot_accessories) - (highlight and google it using those words as I cant post links )

My other idea was to buy some UHMW strips and route them to the same profile as the inserts - although I'd have to finish making my router table first! chicken and egg almost - then add bolts, nuts whatever to the underside (drill a slightly smaller hole and bang it in flush), that way you can add whatever bolt / nut size you prefer.

Alternatively I found an american company that does the same slider kit from rutlands, but much cheaper; $6.95 a pair - I priced 3 pairs with postage to £19!! a price rutlands won't match even if you buy 15 or more sets - so again a bulk buy would work out well.

Let me know here if you are interested in a bulk buy, or would help with the UHMW idea if you think it has merit.

I think the link you wanted to post is this http://www.mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/ttrack.html

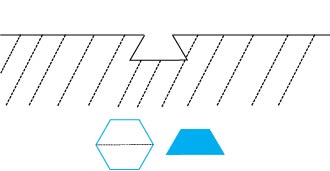

I am in the process of fabricating a sliding table and hold-downs for an old spindle molder (purchased from wallace on this site) that has a cast top with slots that are 'V' shaped with flat bottoms. Since the machine is very old there was no way to buy parts for it, and it occurred to me that a hex bar cut through the middle would work as an insert (in my case the faces are about 10mm each) - this pic illustrates the idea -

Wouldn't it be feasible for you to route a similar 'track' into your table top and similarly cut a piece of hex rod to make the sliding part - whatever length you wish? I plan on cutting mine with a thin (.8mm) disk cutter in an angle grinder - the cut face will end up at the bottom, so will not in practice be a bearing surface and so the accuracy/smoothness is irrelevant.

Cheers

Ed

I am in the process of fabricating a sliding table and hold-downs for an old spindle molder (purchased from wallace on this site) that has a cast top with slots that are 'V' shaped with flat bottoms. Since the machine is very old there was no way to buy parts for it, and it occurred to me that a hex bar cut through the middle would work as an insert (in my case the faces are about 10mm each) - this pic illustrates the idea -

Wouldn't it be feasible for you to route a similar 'track' into your table top and similarly cut a piece of hex rod to make the sliding part - whatever length you wish? I plan on cutting mine with a thin (.8mm) disk cutter in an angle grinder - the cut face will end up at the bottom, so will not in practice be a bearing surface and so the accuracy/smoothness is irrelevant.

Cheers

Ed

JustBen

Established Member

Axminster sell T-track. I got a length the other day. I think it was about £7 for 900mm.

They also do dovetail t-track and slotted track.

I thought it was not a bad price.

They also do dovetail t-track and slotted track.

I thought it was not a bad price.

rafezetter

Troll Hunter

Hi - ordinarily a workaround would be fine...problem is I impulse bought 4 x 48" x 3/4 t-track from rutlands while it was on sale (still is :S at £39.95 for 4) for my router table yet to be made, and didn't realise it was sort of "non standard" i.e. too wide to fit most other workarounds like grinding bolt heads / flange nuts etc etc.

The link I showed was for the 3/4 wide track BUT it was paired with a t-slot bar that was an exact match to the negative "hole" of the track, but hollow at the bottom - so rather than buying "sliders" at £10 a pair from rutlands that are just over an inch long you have an extruded ali bar you can cut as you like, and tap / add nuts and bolts as you please, make into a "no pull out" mitre bar - whatever.

I know many people have their bits already for such things, I just wondered if there was enough interest from those who don't to warrant a group buy.

The link I showed was for the 3/4 wide track BUT it was paired with a t-slot bar that was an exact match to the negative "hole" of the track, but hollow at the bottom - so rather than buying "sliders" at £10 a pair from rutlands that are just over an inch long you have an extruded ali bar you can cut as you like, and tap / add nuts and bolts as you please, make into a "no pull out" mitre bar - whatever.

I know many people have their bits already for such things, I just wondered if there was enough interest from those who don't to warrant a group buy.

As a workaround, can you not plane up a piece of hardwood to fit the track that you have? Wouldn't be as difficult as metal working and easier to drill/cut to length afterwards. I know it may be a pain, but an hour spent producing something could provide you with plenty. If you can do it in something that can be tapped, or has a metric thread, Banbury plastic fittings do loads of plastic hand wheels- male and female for a few pance each.

rafezetter

Troll Hunter

I've thought about hardwood - have some oak strips lying about, but I don't know how the small lip will hold up to stresses from featherboards etc - I could be worrying over nothing, but I'm a bit "sort it once, now and for all", so thought metal or UHMW idea had more longevity.

I guess you are right though.

I guess you are right though.

ossieosborne

Established Member

Square or rectangular aluminium tube stock is available from most metal stockists in various sizes. It should be possible to rout a slot along the length of it with a suitable cutter.

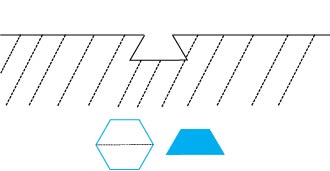

Another alternative, that i've used on several machines, is to make the T track using MDF. Say, for instance, you want a T track along the length of a homemade fence for a saw: Source some suitable sized nuts or T bolts. I make my own T bolts from roofing bolts; File the top of the head flat (to remove the cross slot) and then file two flats on the side of the head. From a 6mm roofing bolt you will have roughly 10mm to 11mm across the flats.

Select a straight router cutter slightly larger than the width of your Tee. Set up your router table fence to cut a dado along the length of the fence (normally centred). Cut the dado to a depth of just over the thickness of the T bolt head. Leave the router fence where it is.

Fix a suitable length and width piece of 9mm MDF to the top of the saw fence. Fit a 6.3mm straight cutter in the router. Now rout a slot through the 9mm MDF and you have a T track.

This is my drill press table with 4 T tracks:

Oz

Another alternative, that i've used on several machines, is to make the T track using MDF. Say, for instance, you want a T track along the length of a homemade fence for a saw: Source some suitable sized nuts or T bolts. I make my own T bolts from roofing bolts; File the top of the head flat (to remove the cross slot) and then file two flats on the side of the head. From a 6mm roofing bolt you will have roughly 10mm to 11mm across the flats.

Select a straight router cutter slightly larger than the width of your Tee. Set up your router table fence to cut a dado along the length of the fence (normally centred). Cut the dado to a depth of just over the thickness of the T bolt head. Leave the router fence where it is.

Fix a suitable length and width piece of 9mm MDF to the top of the saw fence. Fit a 6.3mm straight cutter in the router. Now rout a slot through the 9mm MDF and you have a T track.

This is my drill press table with 4 T tracks:

Oz

Attachments

Similar threads

- Replies

- 0

- Views

- 335

- Replies

- 0

- Views

- 307