dedee

Established Member

I could not bear the thought of my only completed project in 2005 being a shooting board so I am claiming this as a finished project

Well I suppose it is not really finished but it is leaving my workshop. My FIL will take it home this week and if my identification system remains intact and I can remember the coding I should be able to put it all back together again in the spring.

WIP

With the table saw wedged in the middle of the workshop I could just manage to rip 62" long boards with barely an inch to spare at each end. The shop built out-feed table consists of a 4x2 held in the workmate with a strip of 1/4" ply nailed to the top.

I do enjoy using this low angle smoother with the mouth open and the

iron well down roughing out is a delight. By narrowing the mouth and

pulling the iron back a silky smooth finish soon appears.

Oh and those curlies just keep on coming.

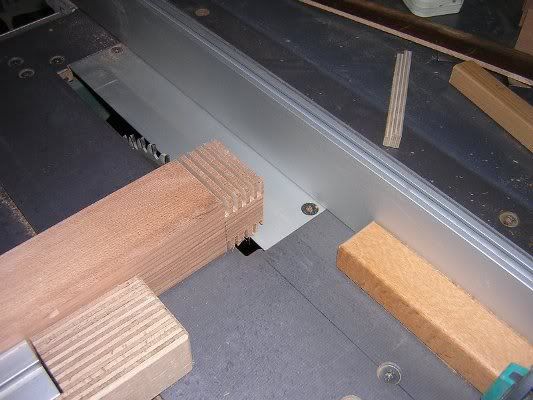

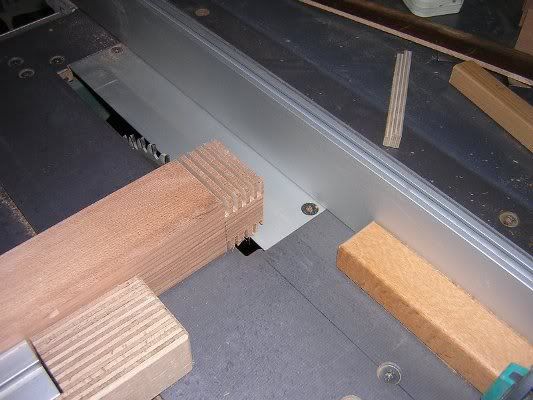

I am not convinced about this method of cutting the tenons. Care is needed as the blade is exposed. The secondary fence should be way in front of the blade to prevent pinching between the blade and the fixed fence. It is also important not to turn the secondary fence over half way though as the resulting tenons will be a different sizes DAMHIKT!

With the cedar being so soft the waste just snapped off with just light finger pressure.

Cleaning the rough spots on the tenon with a chisel. The shoulders were all very clean straight from the saw although I think I went too far with the shoulder depth.

As the cedar is very soft I found it best to cut the mortise very tight.

I added angled braces on each of the front frame corners to aid stability. The back is held rigid by the shiplap and when all four frames are bolted together the whole thing is very rigid - even without glue on the joints.

This is the final dry fit. 100% Cedar and smells gorgeous. 1.6m High at the back, 1.2m wide and 0.5m deep.

The glass will be secondary glazing panels. The top one will hinge from the back the sides will be fixed and two panels at the front will also be hinged. The glass is at the home of my FIL (in Normandy), I can only hope that we got all the measurements correct.

I purchased most of the timber in January last year and did the first cuts on the 6th March. Not much to show for 10 months work. Up until about 2 weeks ago I think the longest period I spent working on this was 2 hours. Sometimes I managed to cut and fit just one joint in a session. This is not ideal and probably lead to a number of mistakes.

I made 4 trips to 3 timber yards before I got all the wood required. I must take more care when calculating requirements next time.

I have mentioned before how soft cedar is. When knocked it seems to leave a disproportionately sized dent.

FIL is very pleased and if it all goes back together next year then so shall I be.

Along with the shooting board and the jack plane fence that is 3 completed projects in 2005!

Andy

Well I suppose it is not really finished but it is leaving my workshop. My FIL will take it home this week and if my identification system remains intact and I can remember the coding I should be able to put it all back together again in the spring.

WIP

With the table saw wedged in the middle of the workshop I could just manage to rip 62" long boards with barely an inch to spare at each end. The shop built out-feed table consists of a 4x2 held in the workmate with a strip of 1/4" ply nailed to the top.

I do enjoy using this low angle smoother with the mouth open and the

iron well down roughing out is a delight. By narrowing the mouth and

pulling the iron back a silky smooth finish soon appears.

Oh and those curlies just keep on coming.

I am not convinced about this method of cutting the tenons. Care is needed as the blade is exposed. The secondary fence should be way in front of the blade to prevent pinching between the blade and the fixed fence. It is also important not to turn the secondary fence over half way though as the resulting tenons will be a different sizes DAMHIKT!

With the cedar being so soft the waste just snapped off with just light finger pressure.

Cleaning the rough spots on the tenon with a chisel. The shoulders were all very clean straight from the saw although I think I went too far with the shoulder depth.

As the cedar is very soft I found it best to cut the mortise very tight.

I added angled braces on each of the front frame corners to aid stability. The back is held rigid by the shiplap and when all four frames are bolted together the whole thing is very rigid - even without glue on the joints.

This is the final dry fit. 100% Cedar and smells gorgeous. 1.6m High at the back, 1.2m wide and 0.5m deep.

The glass will be secondary glazing panels. The top one will hinge from the back the sides will be fixed and two panels at the front will also be hinged. The glass is at the home of my FIL (in Normandy), I can only hope that we got all the measurements correct.

I purchased most of the timber in January last year and did the first cuts on the 6th March. Not much to show for 10 months work. Up until about 2 weeks ago I think the longest period I spent working on this was 2 hours. Sometimes I managed to cut and fit just one joint in a session. This is not ideal and probably lead to a number of mistakes.

I made 4 trips to 3 timber yards before I got all the wood required. I must take more care when calculating requirements next time.

I have mentioned before how soft cedar is. When knocked it seems to leave a disproportionately sized dent.

FIL is very pleased and if it all goes back together next year then so shall I be.

Along with the shooting board and the jack plane fence that is 3 completed projects in 2005!

Andy