Hello all,

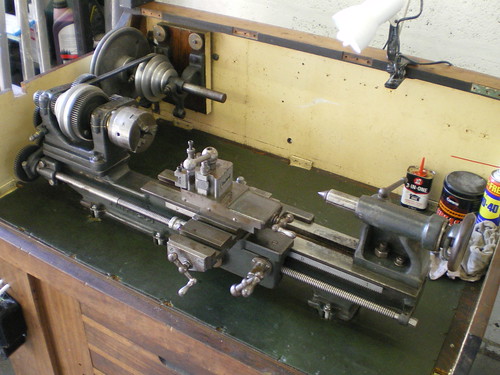

I have been thinking that a small metal working lathe would be a useful and handy addition to the workshop.

The ability to make thumb screws, knurled knobs, bushes, ferrels, small items and parts for making tools etc. would be very useful and fun.

I am waiting for a friend of mine to make a few small items I need for my secret santa gift. :wink: It would be nice to make these in house.

I will take some advice from him on this subject, he has a large lathe and also a Myford super 7.

I know that one or two of our forum friends have metal working lathes, Philly and Ed. Does anybody else have a small lathe for metal work?

Axminster sell a range of Sieg machines, which also look like machines offered by Warco, Chester and Sealey. Are these all the same? Which is the best make?

A Sieg C3 is available on ebay for only £375 which seems good value.

I am in no hurry for this item, but would like to hear views from the forum on this subject.

Any ideas?

Cheers, Tony.

I have been thinking that a small metal working lathe would be a useful and handy addition to the workshop.

The ability to make thumb screws, knurled knobs, bushes, ferrels, small items and parts for making tools etc. would be very useful and fun.

I am waiting for a friend of mine to make a few small items I need for my secret santa gift. :wink: It would be nice to make these in house.

I will take some advice from him on this subject, he has a large lathe and also a Myford super 7.

I know that one or two of our forum friends have metal working lathes, Philly and Ed. Does anybody else have a small lathe for metal work?

Axminster sell a range of Sieg machines, which also look like machines offered by Warco, Chester and Sealey. Are these all the same? Which is the best make?

A Sieg C3 is available on ebay for only £375 which seems good value.

I am in no hurry for this item, but would like to hear views from the forum on this subject.

Any ideas?

Cheers, Tony.