scooby

Established Member

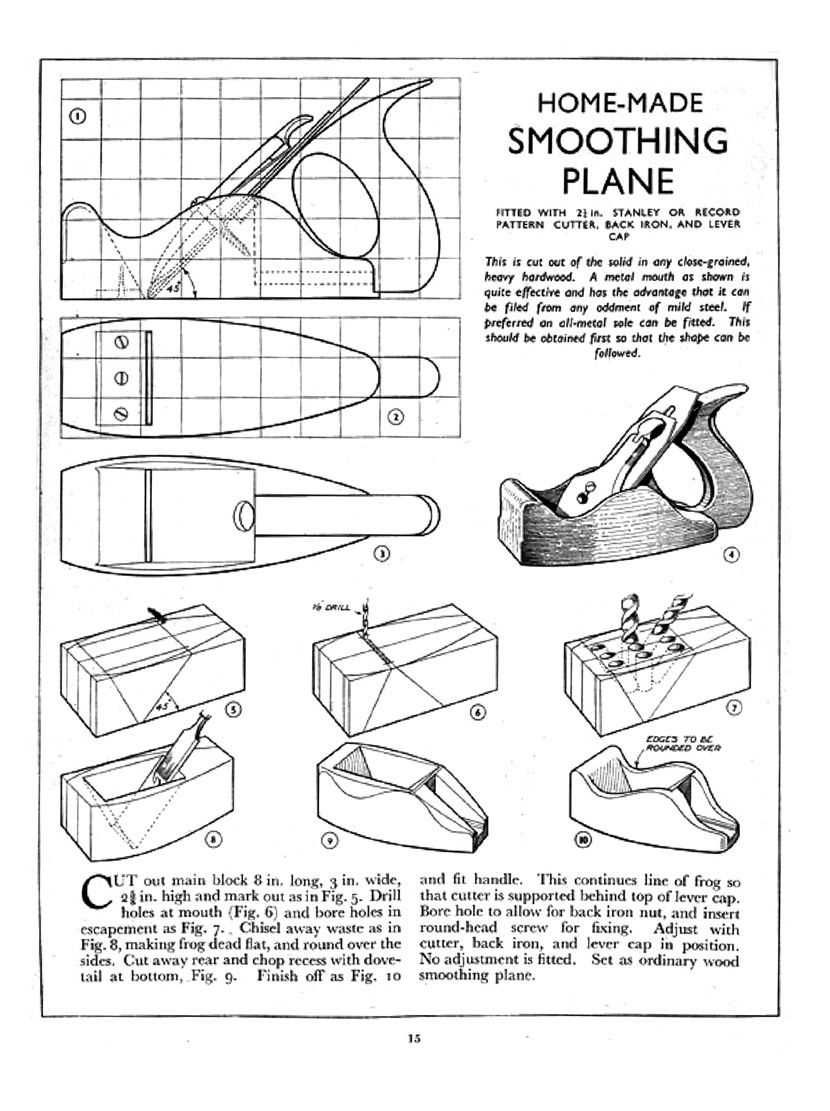

Last year, I removed the parts from a broken no.4 with the intention of making a wooden plane with a adjustable metal frog. Much like the wooden planes Marples. I've cut and ground down the frog (last year) so thats ready.

I was just wondering if anyone here had made such a thing and could give me some dimensions and advice. I'd imagine sole thickness would the most important thing to consider for rigidity but still allow blade protrusion.

I've looked online but couldn't find any dimensions. Paul Sellers did a blog post on his version a few years ago and it looked like he would do a video series but it never appeared.

Also, would oak be ok to use? I know beech is the preferred choice but I dont have any, whereas I had a loads of oak scrap pieces and japanese planes are usually oak. Thats my thinking anyway but I dont mind buying some beech if needed.

I was just wondering if anyone here had made such a thing and could give me some dimensions and advice. I'd imagine sole thickness would the most important thing to consider for rigidity but still allow blade protrusion.

I've looked online but couldn't find any dimensions. Paul Sellers did a blog post on his version a few years ago and it looked like he would do a video series but it never appeared.

Also, would oak be ok to use? I know beech is the preferred choice but I dont have any, whereas I had a loads of oak scrap pieces and japanese planes are usually oak. Thats my thinking anyway but I dont mind buying some beech if needed.