paulm

IG paulm_outdoors

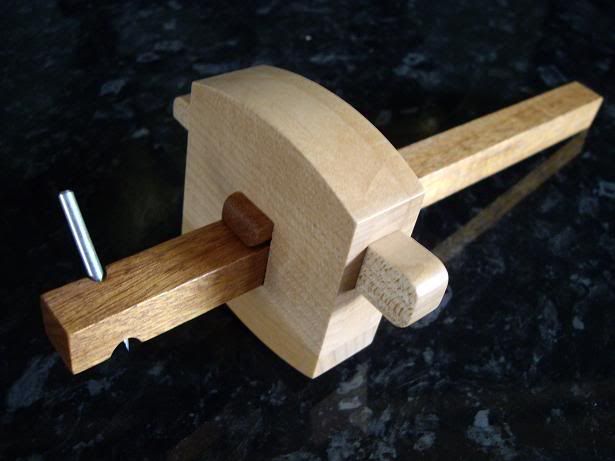

Thanks to Rob (Woodbloke) and Paul Chapman for earlier postings on making your own marking gauges, and particularly inspired by the one Rob made and gave to Philly at Yandles a few months ago, I decided to have a bit of fun making my own.

Had to consult with both Rob and Paul over some of the techniques and best way to go about it, and here is the end result:

Main body is laminated from a piece of iroko or sapele (not sure which), with the stock, saddle and wedge from oak. Just had one coat of danish so far, need to wax it later as well.

Quite pleased with the first attempt. Need to work on making the tolerances finer on the next one now that I have the general idea and proportions.

Thanks for the idea and the help guys !

Cheers, Paul.

Had to consult with both Rob and Paul over some of the techniques and best way to go about it, and here is the end result:

Main body is laminated from a piece of iroko or sapele (not sure which), with the stock, saddle and wedge from oak. Just had one coat of danish so far, need to wax it later as well.

Quite pleased with the first attempt. Need to work on making the tolerances finer on the next one now that I have the general idea and proportions.

Thanks for the idea and the help guys !

Cheers, Paul.