Hattori-Hanzo

Established Member

Hi all, I know a lot of you are interested in build projects so I thought I'd start a thread on something I've been wanting to make for a long time.

It's nice to document the progress and have an on-line diary of how things are going. I've actually started the same thread on another forum and a member there recommenced this forum to me and I'm glad he did as I've already seen a lot of excellent threads here.

I use hand planes every day and I've always lusted after a high quality bespoke plane, like a Lazarus, Holtey, Bill Carter etc but the price of these planes can go into the thousands and my pockets just aren't deep enough.

So making one is the next best thing. The only trouble is I've never done a day of metal work in my life.

Woodwork yes but metal work is a whole other ball game.

So how well this project will turn out is any ones guess.

I've done a fair few hours research into making infill planes and am confident in the process...mostly.

I've taken a lot of inspiration from Carter's and Lazurus planes, the planes they produce are amazing.

So i think the best thing to do is get stuck in!

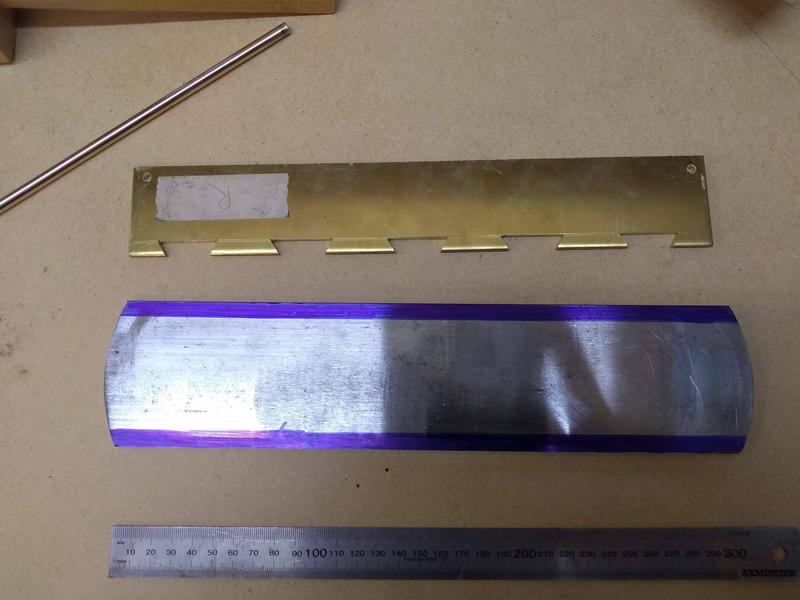

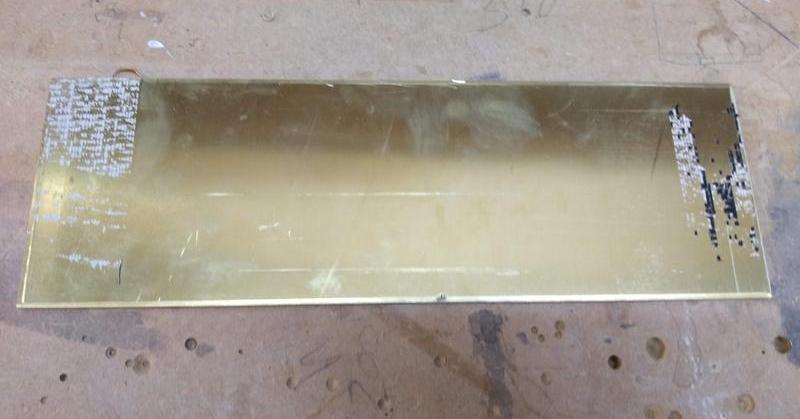

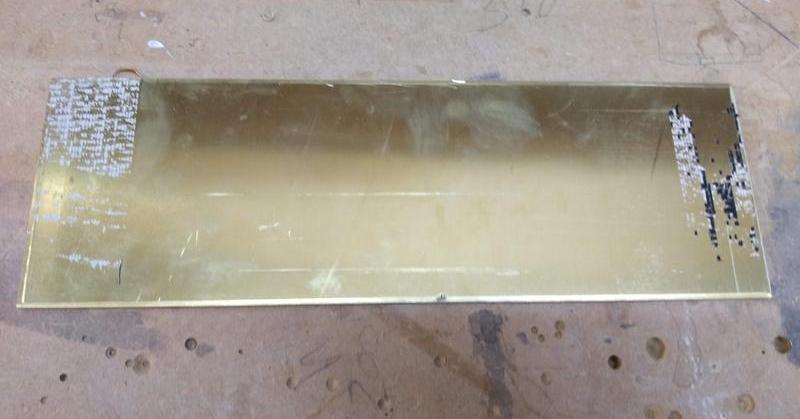

First things first I ordered some 4mm CZ108 brass 300mm long by 100mm wide.

I then cut it in half on the band saw.

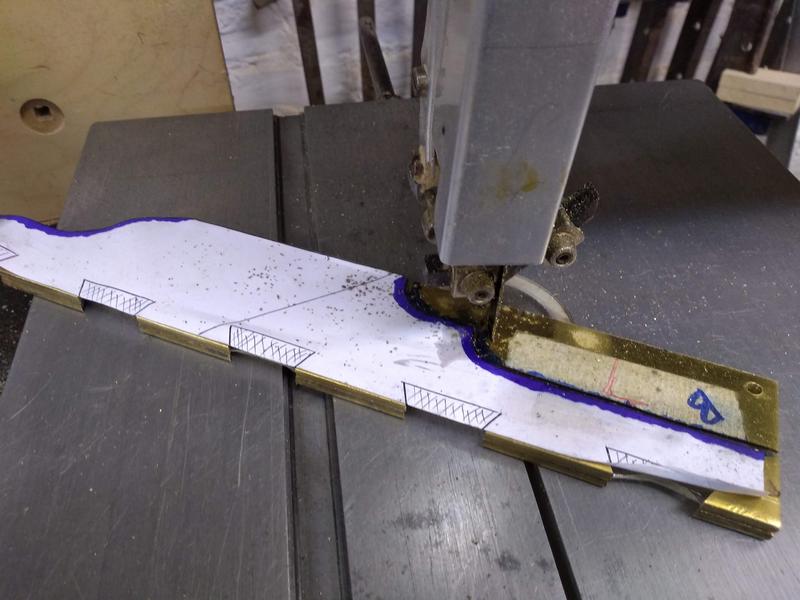

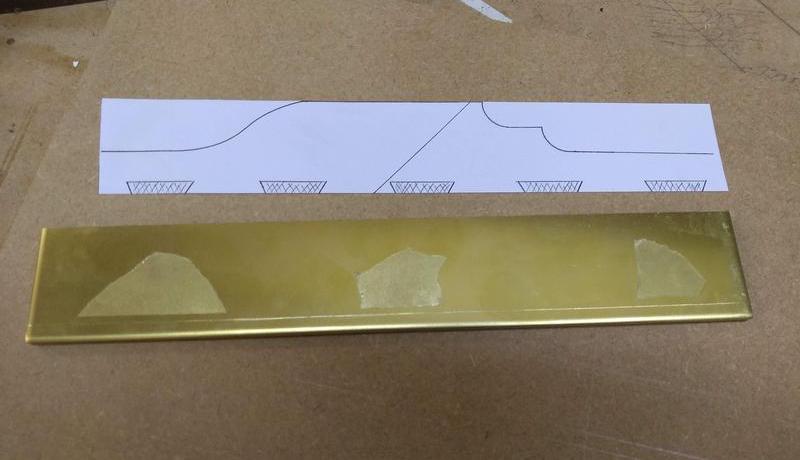

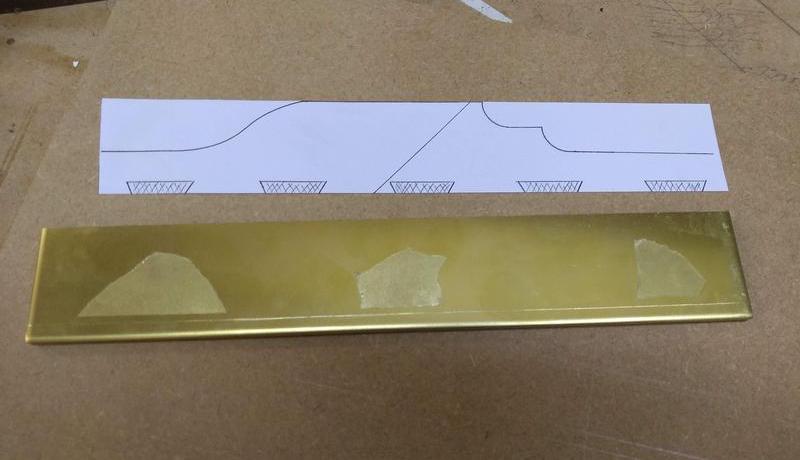

I made a paper template of the sides of the plane working out the dovetail spacing.

And again cut them roughly on the band saw.

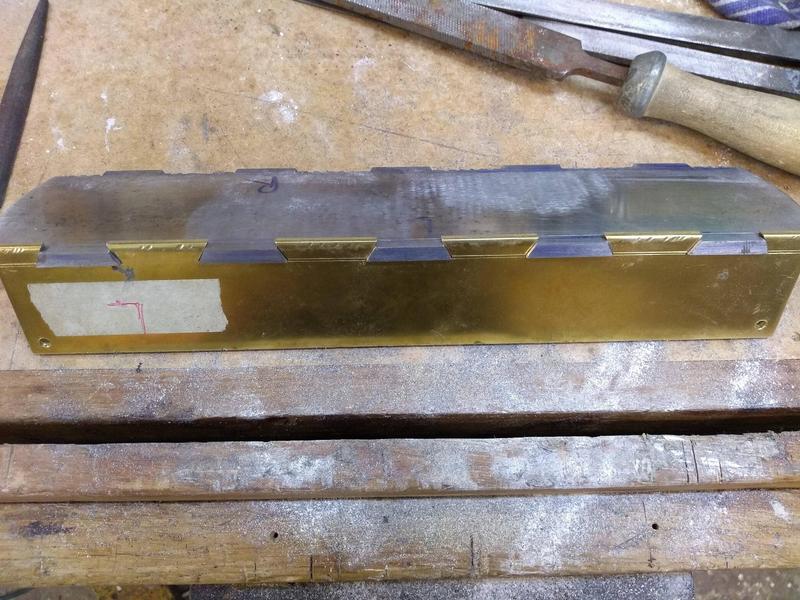

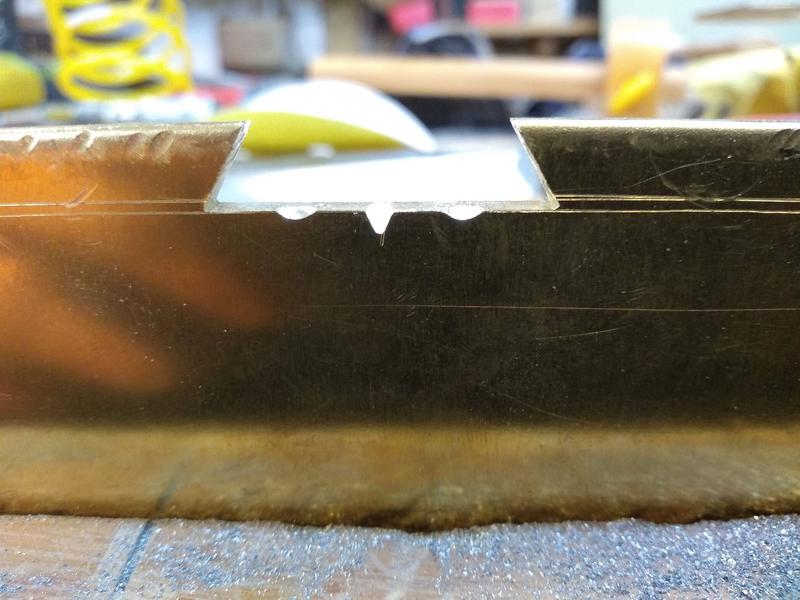

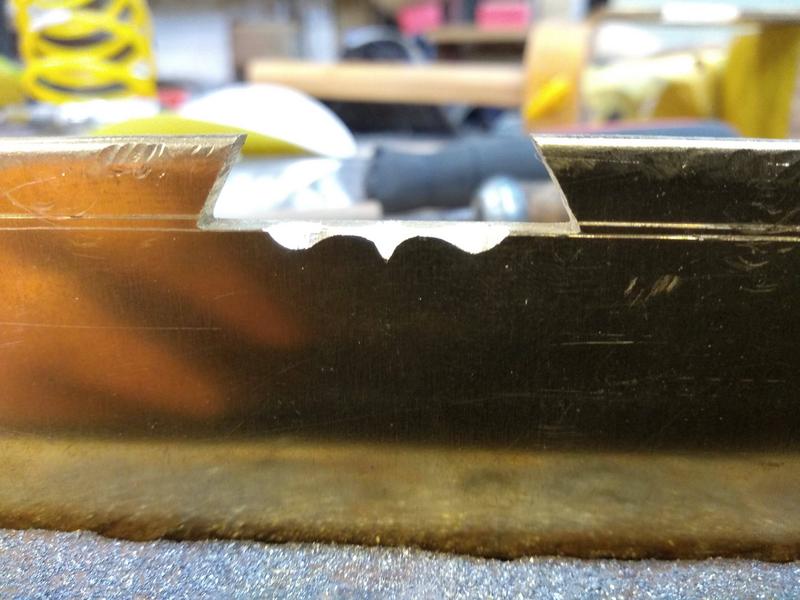

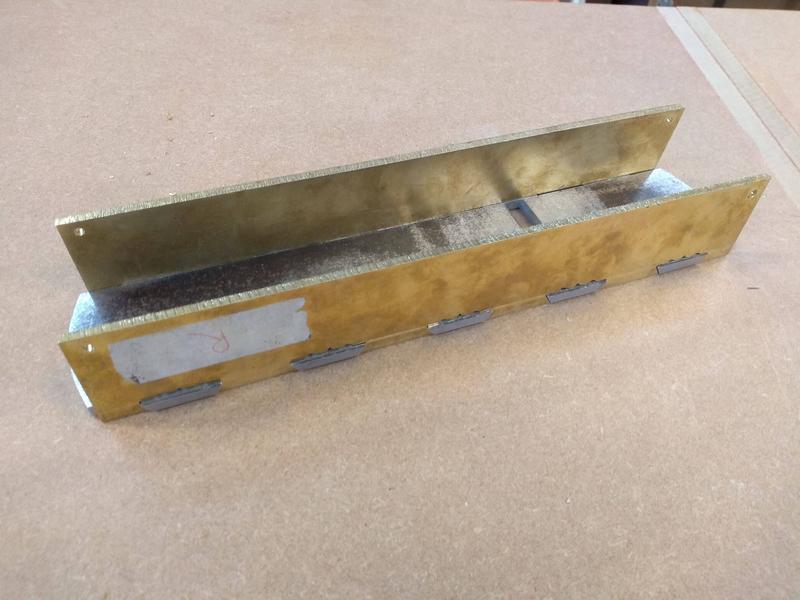

After cutting the dovetails roughly on the band saw I spent the next 3 hours filing them.

This was tedious work as the tails had to be square bottomed and as straight as possible, getting into the corners was difficult.

Any miss shaped tails would result in gaps later on.

I later found out that grinding the teeth off one side of a triangular file greatly helps in getting sharp clean corners. It did indeed make the job a lot easier and the results where far better than using a half round file.

After 3 hours they are still not quite finished but the majority is done.

After that I marked out and started cutting the sole of the plane from a piece of 6mm mild steel.

I've since learnt that 01 tool steel is a far better choice for the sole as it is accurately machined and harder.

The mild steel was freely available at the time so I went with it. It should be a little easier to cut and file over tool steel.

That little lot was enough for one evening.

As I'll only be working on the plane in the evenings its going to be a lengthy project but I'll keep this thread updated as and when more is done.

It's nice to document the progress and have an on-line diary of how things are going. I've actually started the same thread on another forum and a member there recommenced this forum to me and I'm glad he did as I've already seen a lot of excellent threads here.

I use hand planes every day and I've always lusted after a high quality bespoke plane, like a Lazarus, Holtey, Bill Carter etc but the price of these planes can go into the thousands and my pockets just aren't deep enough.

So making one is the next best thing. The only trouble is I've never done a day of metal work in my life.

Woodwork yes but metal work is a whole other ball game.

So how well this project will turn out is any ones guess.

I've done a fair few hours research into making infill planes and am confident in the process...mostly.

I've taken a lot of inspiration from Carter's and Lazurus planes, the planes they produce are amazing.

So i think the best thing to do is get stuck in!

First things first I ordered some 4mm CZ108 brass 300mm long by 100mm wide.

I then cut it in half on the band saw.

I made a paper template of the sides of the plane working out the dovetail spacing.

And again cut them roughly on the band saw.

After cutting the dovetails roughly on the band saw I spent the next 3 hours filing them.

This was tedious work as the tails had to be square bottomed and as straight as possible, getting into the corners was difficult.

Any miss shaped tails would result in gaps later on.

I later found out that grinding the teeth off one side of a triangular file greatly helps in getting sharp clean corners. It did indeed make the job a lot easier and the results where far better than using a half round file.

After 3 hours they are still not quite finished but the majority is done.

After that I marked out and started cutting the sole of the plane from a piece of 6mm mild steel.

I've since learnt that 01 tool steel is a far better choice for the sole as it is accurately machined and harder.

The mild steel was freely available at the time so I went with it. It should be a little easier to cut and file over tool steel.

That little lot was enough for one evening.

As I'll only be working on the plane in the evenings its going to be a lengthy project but I'll keep this thread updated as and when more is done.