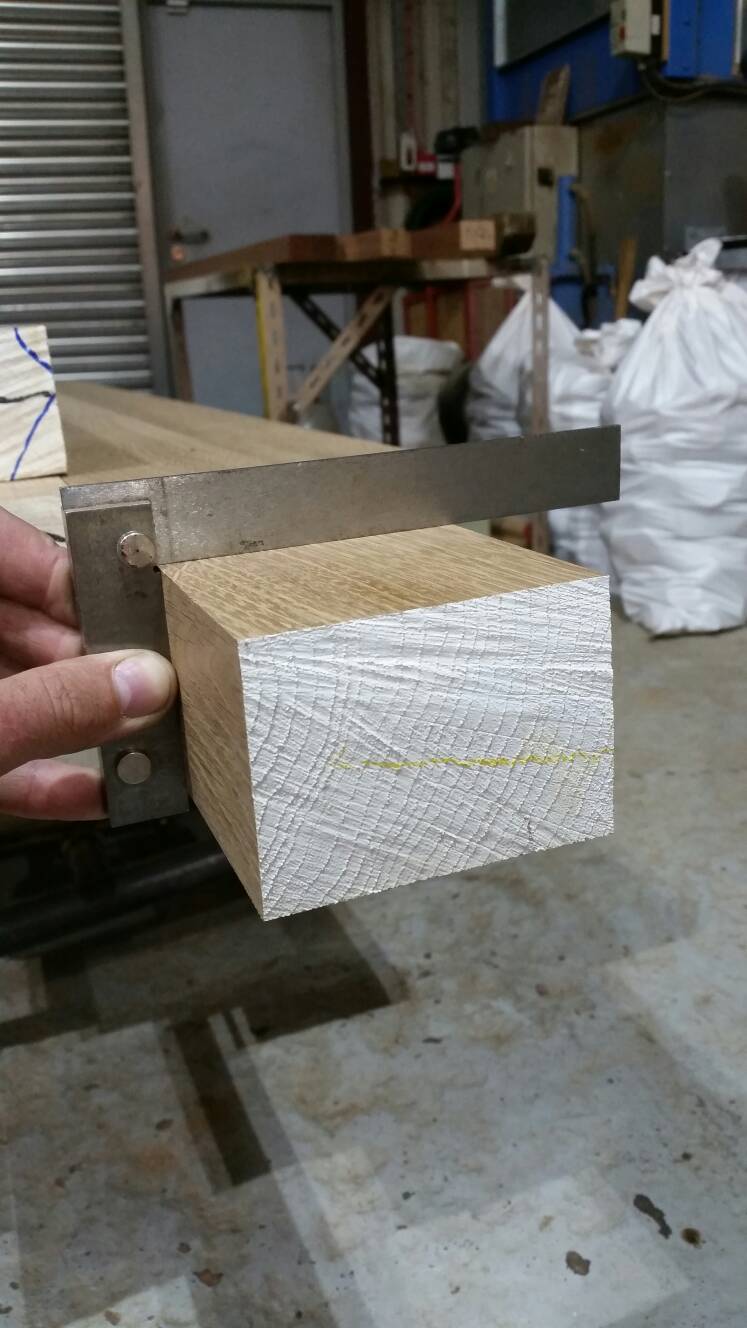

I'm using a precision engineers square to check a planed board for flat and square. I've laboriously set the knives in the cutter head, checked tables are parallel, etc, etc.

When using the square should there be..... no visible light..... at all, how square is square, does perfection exist?

I'm an aspiring woodworker..... not a metal working engineer.... machining tolerances.

Using the square, is very close too, good enough or does it need to be..... exactly, exactly precise?

Thanks.

Surface planing example,

The piece of timber I was checking for square I was given and checked for square when I got it and seemed preety close to that. I faced it and then edged it, repeating several times then checked.

I'm using a new Empire combination square set to measure 5.5 inches, the Empire combination square has a reputation for accuracy. I also checked using a SOBA precision tools engineering square 6 inch one, BS standard 939 grade B Accuracies less than 0.001" deviation per inch over the entire length of blade.

The board is 22 inch long x 5 inch wide. Across the face of the the board I can see a very fine slither of light towards the center of the board. I can pass a 0.1mm feeler through this gap. Towards the edges of the face no feeler gauge will fit.

Checking the edge itself, which is only about an 1/2 inch thick. Along parts of the edge, just on the right hand side of the edge, I can just about pass a 0.5mm feeler gauge but not a 1.0mm feeler gauge.

I checked the timber on the iron table of the table saw, couldn't detect any rocking movement whatsoever.

Thanks.

When using the square should there be..... no visible light..... at all, how square is square, does perfection exist?

I'm an aspiring woodworker..... not a metal working engineer.... machining tolerances.

Using the square, is very close too, good enough or does it need to be..... exactly, exactly precise?

Thanks.

Surface planing example,

The piece of timber I was checking for square I was given and checked for square when I got it and seemed preety close to that. I faced it and then edged it, repeating several times then checked.

I'm using a new Empire combination square set to measure 5.5 inches, the Empire combination square has a reputation for accuracy. I also checked using a SOBA precision tools engineering square 6 inch one, BS standard 939 grade B Accuracies less than 0.001" deviation per inch over the entire length of blade.

The board is 22 inch long x 5 inch wide. Across the face of the the board I can see a very fine slither of light towards the center of the board. I can pass a 0.1mm feeler through this gap. Towards the edges of the face no feeler gauge will fit.

Checking the edge itself, which is only about an 1/2 inch thick. Along parts of the edge, just on the right hand side of the edge, I can just about pass a 0.5mm feeler gauge but not a 1.0mm feeler gauge.

I checked the timber on the iron table of the table saw, couldn't detect any rocking movement whatsoever.

Thanks.