NO NO NO

ITS NOT the VB :lol:

However it is a rather nice Woodfast short bed lathe

This make was manufactured in Newzeland but is now marketed by Record Power as the Maxi

It is a Short Bed lathe , ideal for those with limited room and not wanting to turn big long items

Also It is a low height so ideal for someone who likes to sit down , or is in a wheel chair

It can of coarse be put back to normal height if needed by having or making some longer legs of fitting it to a workbench

It is VERY heavy duty , with a cast flat bed , Cast tail stock , Cast tool rest assembly .

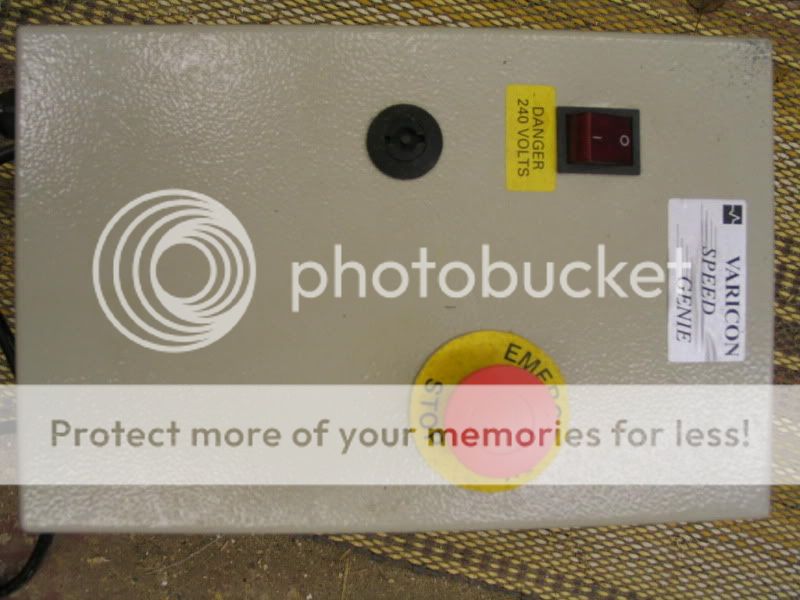

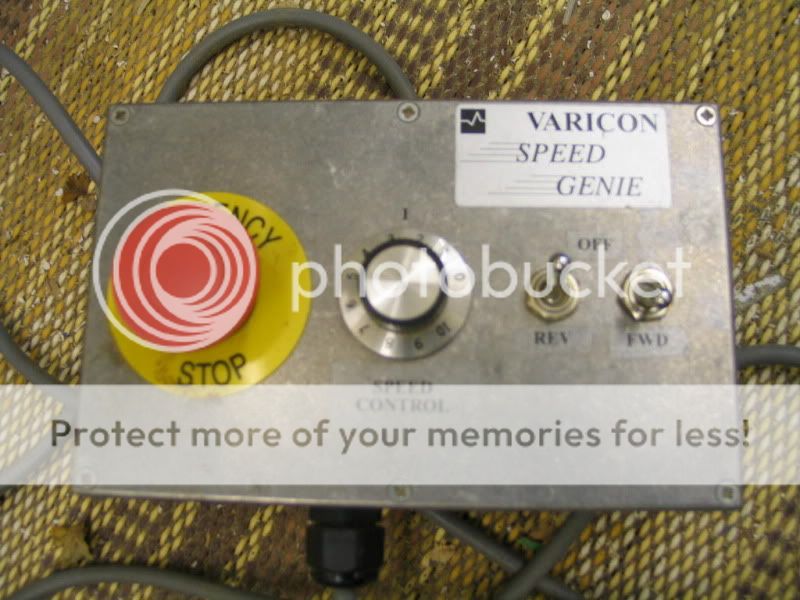

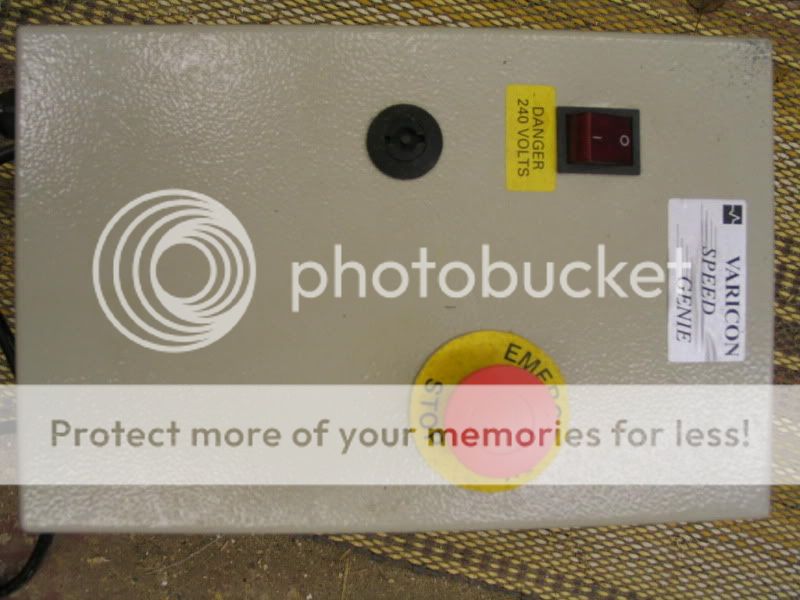

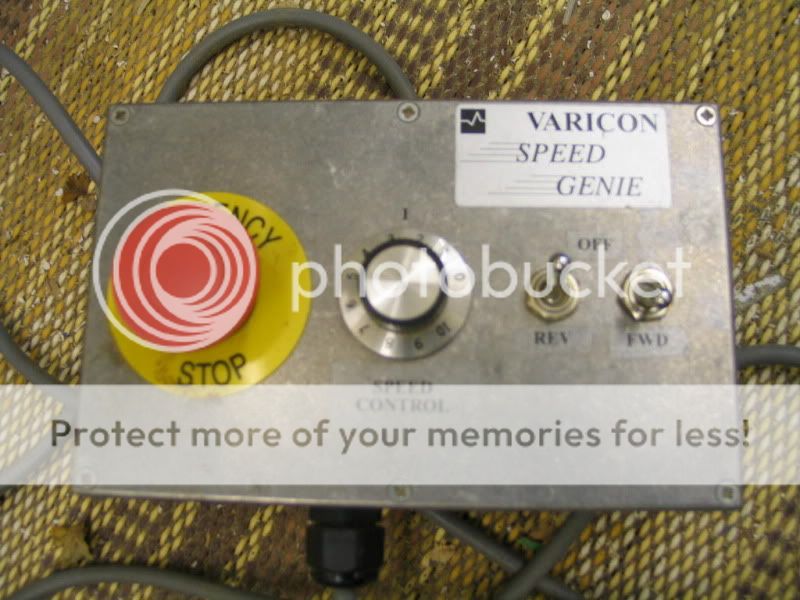

It is also FULL variable speed with a powerful electronic 3 phase motor running through a single phase inverter , Has forward and reverse at the flick of a switch

The head can swivel through 180 to turn off the end of the lathe , and also comes complete with the outside turning table assembly

Axminster chuck with jaws / face plates / knock out bar / revolving center / drive center / tool rests

The electronics and motor are first class and high quality and its whisper quiet 8)

it is a nice piece of lit :mrgreen:

Would make a very nice :ho2 :deer :ho2 :ho2 :deer

prezzy fore someone :wink:

Price £700 all in

If any serious interest I will take some photos tomorrow

:wink:

:ho2 :deer :mrgreen: :tool: :tool: :tool:

ITS NOT the VB :lol:

However it is a rather nice Woodfast short bed lathe

This make was manufactured in Newzeland but is now marketed by Record Power as the Maxi

It is a Short Bed lathe , ideal for those with limited room and not wanting to turn big long items

Also It is a low height so ideal for someone who likes to sit down , or is in a wheel chair

It can of coarse be put back to normal height if needed by having or making some longer legs of fitting it to a workbench

It is VERY heavy duty , with a cast flat bed , Cast tail stock , Cast tool rest assembly .

It is also FULL variable speed with a powerful electronic 3 phase motor running through a single phase inverter , Has forward and reverse at the flick of a switch

The head can swivel through 180 to turn off the end of the lathe , and also comes complete with the outside turning table assembly

Axminster chuck with jaws / face plates / knock out bar / revolving center / drive center / tool rests

The electronics and motor are first class and high quality and its whisper quiet 8)

it is a nice piece of lit :mrgreen:

Would make a very nice :ho2 :deer :ho2 :ho2 :deer

prezzy fore someone :wink:

Price £700 all in

If any serious interest I will take some photos tomorrow

:wink:

:ho2 :deer :mrgreen: :tool: :tool: :tool: