About 3 years ago we started building a kitchen extension.

This was the night before we knocked through from the old kitchen into the extension.

Breakthrough day.

Then reseal the gap with a 12mm OSB wall.

... and put the old units back.

I’ve done a thread covering various aspects of the build, including Bifold Doors, Windows and under floor heating.

Time to move on to fitting out the kitchen. This will be a face frame kitchen with shaker style doors, spray painted in buttermilk or similar, but with lacquered oak end panels and island.

I started with 14 large sheets of Egger MFC, which at 65kgs each were a b***** to carry around from the front of the house . First job is to cut them to manageable sizes. I took the legs off my sacrificial cutting table so that I could just lower each sheet down to near floor level, and cut them up with my T55 plunge saw on guide rails.

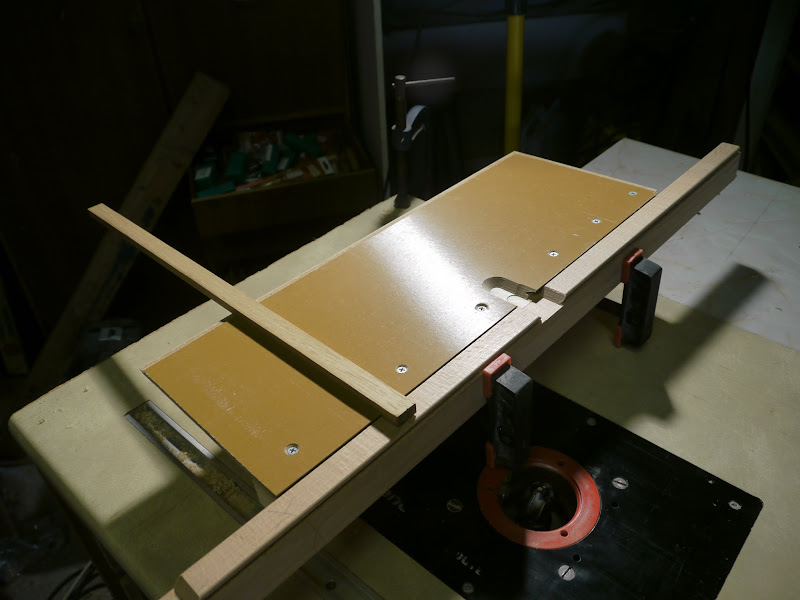

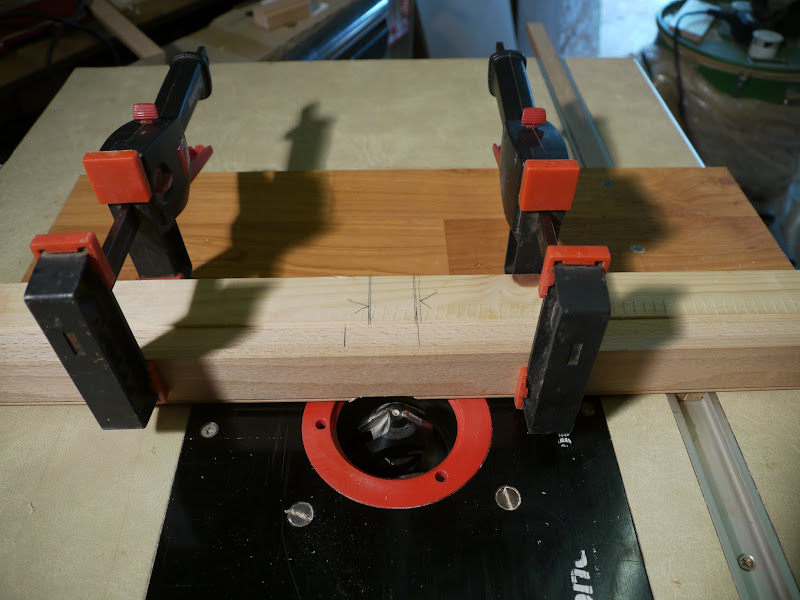

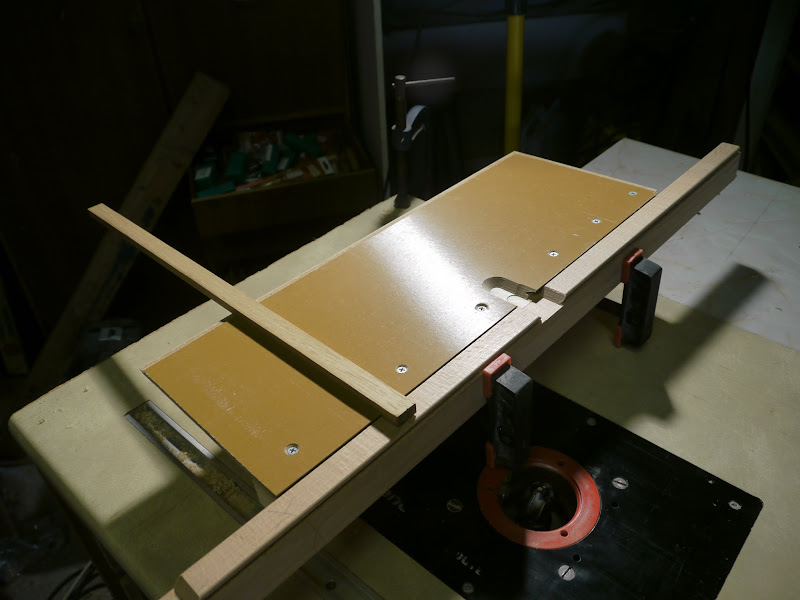

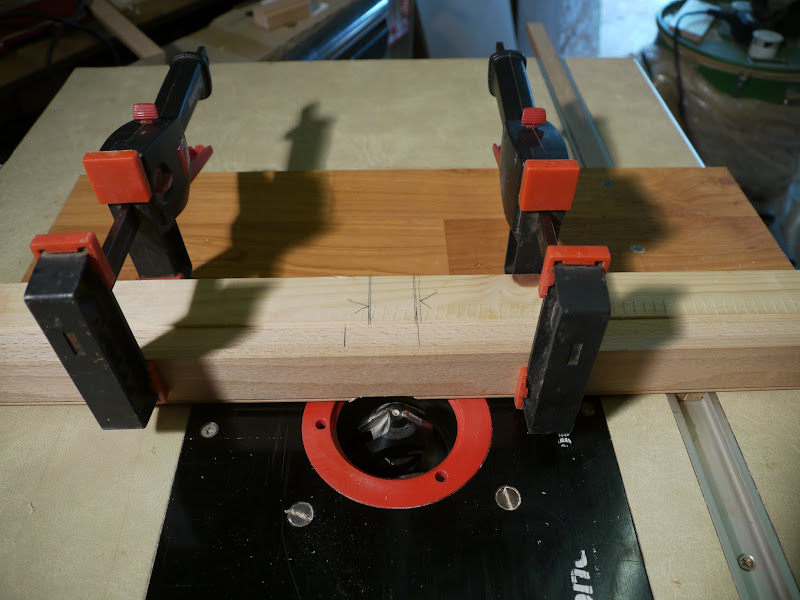

Base and wall units have been constructed using carcase screws and 6mm dominoes. Face frames are in steamed beech with a cockbead cut in using a Wealden mortar groove cutter using the router table and a simple jig. I have a supply of engineered floor boards which are ideal for making router table jigs.

Never having made face frames before I decided that for accuracy I’d use a building board just as I did for the windows and bifold doors. I suspect that is not the way the pros do it, but it works for me. When the MFC was delivered there was a damaged freebie at the base of the pallet which I took off their hands, and although too badly marked to use in the units, it’s ideal for using as a building board, and the melamine surface is easy to mark out in pencil, clean off afterwards, as well as resisting the glue. Here’s a frame for 2 double wall units going together. All joints are dominoed.

I’ve got the base units in along one wall, and the face frames are ready to fit. Dominoes again I think.

Here’s the view into the extended kitchen from the old one. I want to get the new area more or less fitted out and the units built for the existing kitchen before I rip out the old one, so progress will be in definite stages.

The face frames were friction fitted with dominoes around the edges, top and bottom, and they are amazingly secure. Certainly secure enough to accurately fit doors and drawers before taking everything off for painting.

I'm making the doors on the same jig as I used for the frames - that way any minor errors in getting them square will be duplicated in the doors so they should fit nicely. This is where I find that care taken in making the frames accurately has helped no end as I find that the door of the first cabinet along the wall I'm working on fits every opening so I can now run off 6 identical doors on the same jig. If only it was always this easy!

I made the hob units as a 900mm pan drawer unit with a 300mm unit alongside which we planned to use for a "pull out". After hunting for a suitable pull out unit "The Boss" has decided that she can't find one she likes but there are plenty of 150mm pull outs she would be happy with. Reluctantly we decided that not only would that provide the storage we want, but also that it would look aesthetically more pleasing if the pan drawers were central with a 150mm unit either side. So a bit of modification was be required.

This is a big project for one guy working alone on a diy basis! The new room is about 20ft x 12ft, plus the existing kitchen which is 12ft x 13 ft. Along the far wall there will be a sink under the window, and to the right of the sink will be a run of tall units holding the oven, a 500mm larder drawer unit, a 750mm fridge freezer and a 600mm larder fridge. And that's before gutting and fitting the existing kitchen off to the right.

Hopefully this 200 deg panoramic gives some idea of the space I'm working to fill.

There will be a corner seat and Octagonal table in the far RH corner, and an island where my cutting table is currently sited. The current plan is to get the new area completed, apart from the island, then build the units for the old kitchen area before gutting that, getting it replastered and fitting the new units.

Not completely finished at this stage, but decks were cleared for Xmas 2013. The island is temporary - just our old breakfast bar resting on some old units - and the octagonal table is also temporary, cobbled together from some old worktop in the size that we'll eventually have in that corner. This will at least enable us to see whether it is the right size before making something permanent. The chairs are also temporary as eventually there will be a wrap around bench seat in the corner.

Still need to make the cornice, lay the floor and fit the kicking boards.

Still need to make and fit wall units in the old part of the kitchen. There will be a glass fronted dresser unit above the 3 oak units.

Next job was to make the top for the dresser and the surrounding wall units. I couldn't bring myself to get rid of a 3 year old Miele Dishwasher just to fit an integrated one, so it has remained. If it ever packs up I may fit an integrated one at that point.

Final job is to make an Island to replace the temporary one.

First I made basic MFC carcasses, identical to the other base units. Here they are the right side up.

Then turn them over and make a base frame.

the granite top to this will weigh in at 140kgs on its own, so about 200kgs complete, and there would be no way to move it without castors.

The castors are lockable, and I've also fitted some wind down legs, but have found in practice they are not really needed. It's all rock solid with just the brakes applied. One turned over, face frames and end panels were fitted in exactly the same way as they were for the base units.

So here's where we are in autumn 2014.

The dresser needs some spice drawers fitting in the top section.

The base is fitted with Blum tandembox drawers to hold our booze!

The corner has "flymoon" pull out shelves, and the sink has a drawer either side linked by a single drawer front.

This is looking into the old kitchen from the extension.

and this is the new kitchen extension.

We focused on getting the unit internals the way we wanted, and then built units to suit. No more hunting around on hands and knees! The hob is a Siemens 5 ring induction. Absolutely brilliant.

Here's a le mans corner unit, and there is an internal draw inside the top drawer ...

[

... in which SWMBO keeps her spices. It's one of the features she likes best.

Another pair of drawers with a single front around the 2nd sink, and a Hafele pullout waste system for biodegradables.

Then there is a range of tall units to house the oven, larder drawers and fridge/freezer.

The free standing fridge/freezer is 750mm wide, and alongside is an integrated 600mm Siemens fridge, with drawers underneath. Again, the aim was for all the important stuff to be at eye level.

Finally, the finished island.

Fitted with Tandembox drawers and a mixer lift. I still need to replace the temporary MFC mixer shelf with a nice oak one. The mixer is plugged into a socket inside the island so can be used without being moved off the shelf.

Once I've broken the back of the landscaping outside, and in addition to the spice drawers in the dresser, i still need to fit some oak skirting and replace the doors into the hall and utility room. Then the octagonal table which i cobbled together from some scraps of old worktop as a temporary measure needs to be replaced by something "bespoke", and a wrap around corner seat put in to serve it. But - hey - it'll have to wait a bit.

This is the most ambitious project I've ever attempted. The utility room has been refitted in the same style, and overall, there are 41 sets of stainless steel Blum tandembox drawers, 73 door/drawer fronts and 18 oak end panels. This didn't come cheap! Sheet materials came in at £1200, oak and steamed beech at £1100, hinges and drawers at £2950, and white goods at £3800. The biggest ticket item was the Labrador granite at £6500 - but it's beautiful stuff and we don't regret it. then add in 3 sinks and sets of taps, lighting, glue, "fly moon" and "Lemans" corners, over 70 handles, waste systems etc, and the final kitchen fitting bill came close to £18k. But what a joy to work in, and it won't have taken any value off the house.

Anyway - for those that have stayed the course, thanks for reading!

This was the night before we knocked through from the old kitchen into the extension.

Breakthrough day.

Then reseal the gap with a 12mm OSB wall.

... and put the old units back.

I’ve done a thread covering various aspects of the build, including Bifold Doors, Windows and under floor heating.

Time to move on to fitting out the kitchen. This will be a face frame kitchen with shaker style doors, spray painted in buttermilk or similar, but with lacquered oak end panels and island.

I started with 14 large sheets of Egger MFC, which at 65kgs each were a b***** to carry around from the front of the house . First job is to cut them to manageable sizes. I took the legs off my sacrificial cutting table so that I could just lower each sheet down to near floor level, and cut them up with my T55 plunge saw on guide rails.

Base and wall units have been constructed using carcase screws and 6mm dominoes. Face frames are in steamed beech with a cockbead cut in using a Wealden mortar groove cutter using the router table and a simple jig. I have a supply of engineered floor boards which are ideal for making router table jigs.

Never having made face frames before I decided that for accuracy I’d use a building board just as I did for the windows and bifold doors. I suspect that is not the way the pros do it, but it works for me. When the MFC was delivered there was a damaged freebie at the base of the pallet which I took off their hands, and although too badly marked to use in the units, it’s ideal for using as a building board, and the melamine surface is easy to mark out in pencil, clean off afterwards, as well as resisting the glue. Here’s a frame for 2 double wall units going together. All joints are dominoed.

I’ve got the base units in along one wall, and the face frames are ready to fit. Dominoes again I think.

Here’s the view into the extended kitchen from the old one. I want to get the new area more or less fitted out and the units built for the existing kitchen before I rip out the old one, so progress will be in definite stages.

The face frames were friction fitted with dominoes around the edges, top and bottom, and they are amazingly secure. Certainly secure enough to accurately fit doors and drawers before taking everything off for painting.

I'm making the doors on the same jig as I used for the frames - that way any minor errors in getting them square will be duplicated in the doors so they should fit nicely. This is where I find that care taken in making the frames accurately has helped no end as I find that the door of the first cabinet along the wall I'm working on fits every opening so I can now run off 6 identical doors on the same jig. If only it was always this easy!

I made the hob units as a 900mm pan drawer unit with a 300mm unit alongside which we planned to use for a "pull out". After hunting for a suitable pull out unit "The Boss" has decided that she can't find one she likes but there are plenty of 150mm pull outs she would be happy with. Reluctantly we decided that not only would that provide the storage we want, but also that it would look aesthetically more pleasing if the pan drawers were central with a 150mm unit either side. So a bit of modification was be required.

This is a big project for one guy working alone on a diy basis! The new room is about 20ft x 12ft, plus the existing kitchen which is 12ft x 13 ft. Along the far wall there will be a sink under the window, and to the right of the sink will be a run of tall units holding the oven, a 500mm larder drawer unit, a 750mm fridge freezer and a 600mm larder fridge. And that's before gutting and fitting the existing kitchen off to the right.

Hopefully this 200 deg panoramic gives some idea of the space I'm working to fill.

There will be a corner seat and Octagonal table in the far RH corner, and an island where my cutting table is currently sited. The current plan is to get the new area completed, apart from the island, then build the units for the old kitchen area before gutting that, getting it replastered and fitting the new units.

Not completely finished at this stage, but decks were cleared for Xmas 2013. The island is temporary - just our old breakfast bar resting on some old units - and the octagonal table is also temporary, cobbled together from some old worktop in the size that we'll eventually have in that corner. This will at least enable us to see whether it is the right size before making something permanent. The chairs are also temporary as eventually there will be a wrap around bench seat in the corner.

Still need to make the cornice, lay the floor and fit the kicking boards.

Still need to make and fit wall units in the old part of the kitchen. There will be a glass fronted dresser unit above the 3 oak units.

Next job was to make the top for the dresser and the surrounding wall units. I couldn't bring myself to get rid of a 3 year old Miele Dishwasher just to fit an integrated one, so it has remained. If it ever packs up I may fit an integrated one at that point.

Final job is to make an Island to replace the temporary one.

First I made basic MFC carcasses, identical to the other base units. Here they are the right side up.

Then turn them over and make a base frame.

the granite top to this will weigh in at 140kgs on its own, so about 200kgs complete, and there would be no way to move it without castors.

The castors are lockable, and I've also fitted some wind down legs, but have found in practice they are not really needed. It's all rock solid with just the brakes applied. One turned over, face frames and end panels were fitted in exactly the same way as they were for the base units.

So here's where we are in autumn 2014.

The dresser needs some spice drawers fitting in the top section.

The base is fitted with Blum tandembox drawers to hold our booze!

The corner has "flymoon" pull out shelves, and the sink has a drawer either side linked by a single drawer front.

This is looking into the old kitchen from the extension.

and this is the new kitchen extension.

We focused on getting the unit internals the way we wanted, and then built units to suit. No more hunting around on hands and knees! The hob is a Siemens 5 ring induction. Absolutely brilliant.

Here's a le mans corner unit, and there is an internal draw inside the top drawer ...

[

... in which SWMBO keeps her spices. It's one of the features she likes best.

Another pair of drawers with a single front around the 2nd sink, and a Hafele pullout waste system for biodegradables.

Then there is a range of tall units to house the oven, larder drawers and fridge/freezer.

The free standing fridge/freezer is 750mm wide, and alongside is an integrated 600mm Siemens fridge, with drawers underneath. Again, the aim was for all the important stuff to be at eye level.

Finally, the finished island.

Fitted with Tandembox drawers and a mixer lift. I still need to replace the temporary MFC mixer shelf with a nice oak one. The mixer is plugged into a socket inside the island so can be used without being moved off the shelf.

Once I've broken the back of the landscaping outside, and in addition to the spice drawers in the dresser, i still need to fit some oak skirting and replace the doors into the hall and utility room. Then the octagonal table which i cobbled together from some scraps of old worktop as a temporary measure needs to be replaced by something "bespoke", and a wrap around corner seat put in to serve it. But - hey - it'll have to wait a bit.

This is the most ambitious project I've ever attempted. The utility room has been refitted in the same style, and overall, there are 41 sets of stainless steel Blum tandembox drawers, 73 door/drawer fronts and 18 oak end panels. This didn't come cheap! Sheet materials came in at £1200, oak and steamed beech at £1100, hinges and drawers at £2950, and white goods at £3800. The biggest ticket item was the Labrador granite at £6500 - but it's beautiful stuff and we don't regret it. then add in 3 sinks and sets of taps, lighting, glue, "fly moon" and "Lemans" corners, over 70 handles, waste systems etc, and the final kitchen fitting bill came close to £18k. But what a joy to work in, and it won't have taken any value off the house.

Anyway - for those that have stayed the course, thanks for reading!