Richard S

Established Member

I think you might be a little light on the price of the Jet 18, it's closer to 1500 than 1200.

Random Orbital Bob":2f649ykn said:That's the deal I'm talking about....thanks for bringing it to the attention of the rest of the forum

Random Orbital Bob":d5l63pfs said:I'm confused, which specific other saw is a clone of the BS400?

Random Orbital Bob":3hhaziim said:Record Power do badge engineer their lighter class bandsaws. (The BS10, 12 and 250). They are the ones that SIP/Charnwood/Fox etc have clones of. From the 300 upwards they are unique to RP and an original design. Exactly like a Startrite or a Hammer etc. They are made in the Far East but then so is the Startrite 352 and 502 and also many of the Felder machines (and also Jet incidentally).

Random Orbital Bob":2ybh00v9 said:From the 300 upwards they are unique to RP and an original design.

custard":2gg6zh7d said:That's interesting, I understand some of the Felder/Hammer bandsaws have the chassis sub structure made in Italy, but they're all Felder designs and apart from that, as far as I know, they're all made in the Austrian factory. Which bandsaw were you thinking of?

Scouse":1j3lkmvl said:Random Orbital Bob":1j3lkmvl said:From the 300 upwards they are unique to RP and an original design.

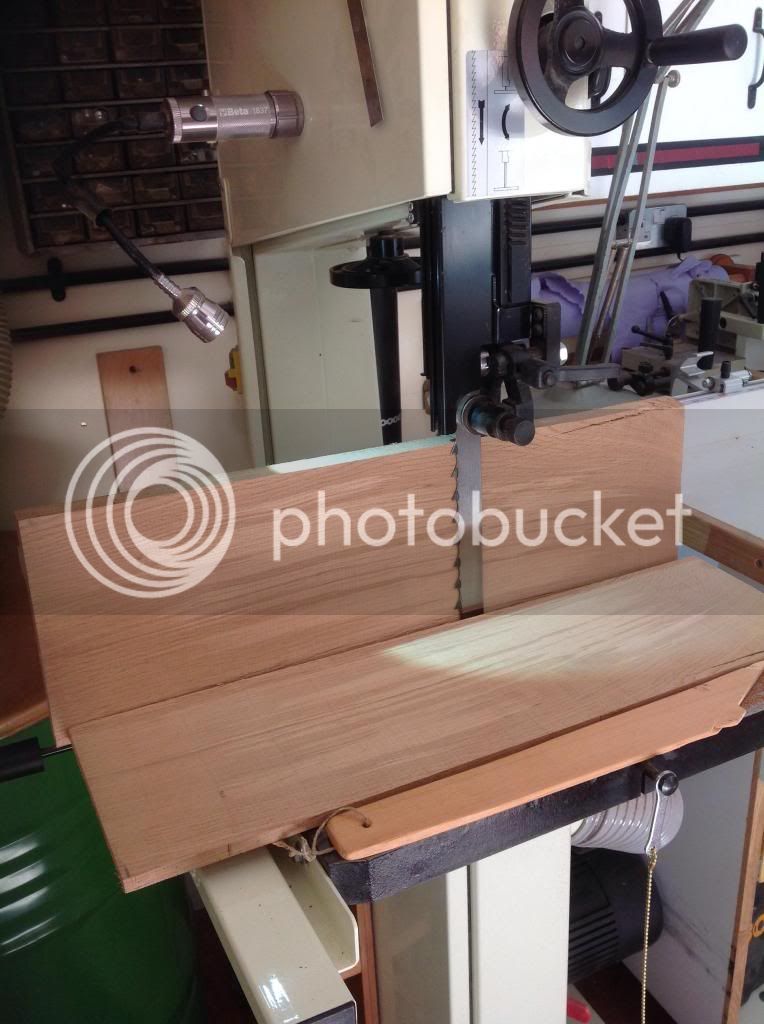

I would suggest that your claim of an original RP design may be somewhat enthusiastic; if you look at the respective saws (the large ones in the BS400 range) beyond details which are easy to alter and bolt on (fences guides etc), the saws below are identical and clearly re-badged versions of the same saw.

http://www.recordpower.co.uk/product/pr ... yQPPM7fSSo

http://www.charnwood.net/shop/product/1 ... dsaw?cid=1

http://www.sipuk.co.uk/sip-16-professio ... -230v.html

As I said, it doesn't make for a bad saw, I just looked for something a bit more thoughtfully designed, albeit also produced in the far east (incidentally, I know this because it has a big sticker on saying 'Made in Taiwan'). Enjoy your BS400.

Random Orbital Bob":20rqw2pw said:Scouse":20rqw2pw said:Random Orbital Bob":20rqw2pw said:From the 300 upwards they are unique to RP and an original design.

I would suggest that your claim of an original RP design may be somewhat enthusiastic; if you look at the respective saws (the large ones in the BS400 range) beyond details which are easy to alter and bolt on (fences guides etc), the saws below are identical and clearly re-badged versions of the same saw.

http://www.recordpower.co.uk/product/pr ... yQPPM7fSSo

http://www.charnwood.net/shop/product/1 ... dsaw?cid=1

http://www.sipuk.co.uk/sip-16-professio ... -230v.html

As I said, it doesn't make for a bad saw, I just looked for something a bit more thoughtfully designed, albeit also produced in the far east (incidentally, I know this because it has a big sticker on saying 'Made in Taiwan'). Enjoy your BS400.

So perhaps when a manufacturer says their machine is unique what they actually mean is the pallet its shipped on is a different colour to everyone elses!!!

Random Orbital Bob":2a61hcgh said:It looks to me like each brand is using the same frame and then altering everything from that point forward to customise it for their needs.

Enter your email address to join: