Derek Cohen (Perth Oz)

Established Member

This bench is done. Time to move on.

I am very happy with the way it has turned out. Somewhat relieved and always a little amazed when things work out. Here are the finishing touches, plus a road test to illustrate the work holding areas.

When we left off last the bench had reached this stage ...

I returned to the fray on the weekend. The first task was to build the shelf. This is made of 5/8" thick (after levelling) Jarrah. I glued the panel up last week. Its weight adds another 10 kg (22 lbs) to the total, bringing the final weight of the bench to 192 kg or 422 lbs.

I was planing the panel with The Dreadnought (36" Jarrah jointer). The quickest way to flatten I know ...

... using one bench dog and a makeshift stop, when I decided I was going about this in the wrong order. Get the round dog holes done! So I sharpened up a 3/4" Jennings bit and brought out the 12" MF brace ...

I do like this brace. It has the simplicity of a Spofford, but with bling

Soon I had lined up a series of holes opposite the square dogs, each 1" in from the far side of the bench ...

I have chosen to use the brass Veritas dogs. A slight modification is the addition of suede leather on the flat face.

These are long enough to pass through the bench top.

The purpose here is to plane across the bench ...

The bench is now 12" from the far wall. This allows the use of a jointer or jack plane without danger of hitting the wall. It was not possible to work this way when the old bench was attached to the wall.

The new shelf ..

It will hold tools such as a shooting board, Moxon vise, and bench hooks.

Alongside the last two square dogs I added two rows of round dog holes. These are coplanar, enabling a short or long bench stop to span the bench. I have yet to make a couple of stops that will be clamped in the leg vise. The following one was co-opted into use in the short term ...

The leg vise was given a layer of 2mm thick suede leather on each side. This makes a huge difference to the work holding power of the leg vise. It will now clamp pieces securely with little force.

One other point about the leg vise - add the supporting wheels to the glide, as designed by Jameel Abraham, and this will create a smooth running screw, even the wooden one on this bench. I can spin the handle, and the chop will slide in-or-out freely.

My old bench was 34" high. For my height of 5"10" the "pinky test" of Chris Schwarz would point to a bench height of 30" as ideal for planing. My concern, however, was that there are a number of tasks that need to be done at a bench, not just planing. Would the bench be high enough for marking and other detail work? In the end I decided to compromise on a height of 32".

Marking with a gauge is comfortable ...

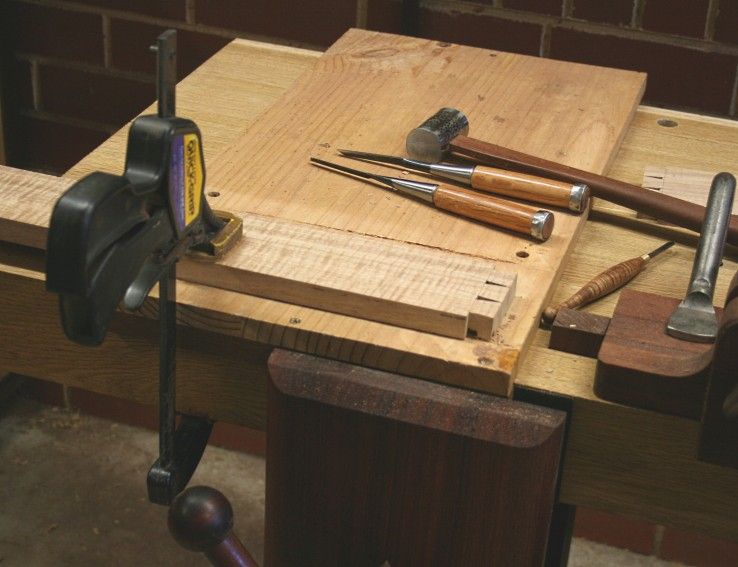

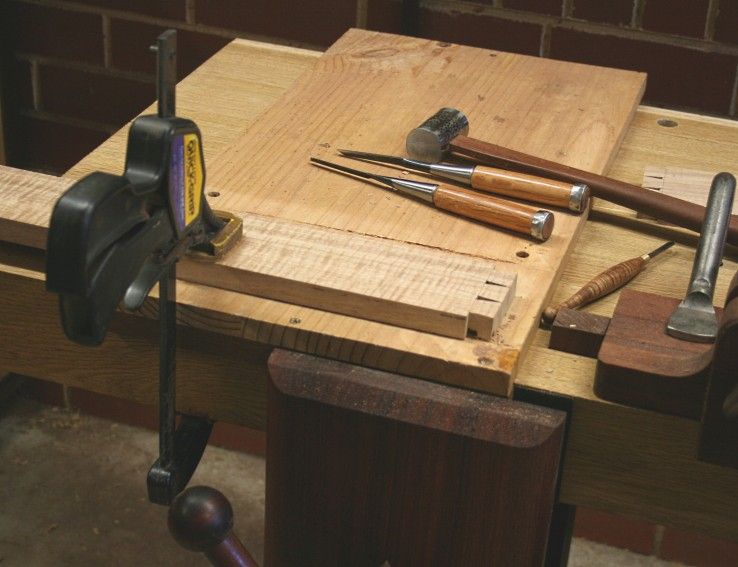

The Moxon dovetail vise is positioned against a dog, and clamped down by two holdfasts at the rear (which may assitionally be used in any of the round dog holes)..

Marking dovetails is also fine, but sawing is less comfortable at this height than before. The saw has to angle upward and I can feel my wrist having to **** more than I like ..

Cross-cutting (the tails) is another comfortable position ..

A bench hook clamped into the leg vise allows chopping to take place over a leg ...

It has never been this easy to hold work to plane a rebate along an edge ...

I scratched my head for a while how to hold the short ends. Then I remembered I had a tail vise! Easy peasy ..

Finally, the sliding deadman, along with the new Veritas surface clamp, made it easy to hold the completed box for planing ..

So what was the first project being built on the new bench? It will become a tool tray, one that will attach to the wall instead of the bench. I want to leave the edges of the bench free for clamps, if needed. To the tool tray I will add a section to hold a few chisels and backsaws that are in current use. That is for a later date.

The completed bench ...

Regards from Perth

Derek

I am very happy with the way it has turned out. Somewhat relieved and always a little amazed when things work out. Here are the finishing touches, plus a road test to illustrate the work holding areas.

When we left off last the bench had reached this stage ...

I returned to the fray on the weekend. The first task was to build the shelf. This is made of 5/8" thick (after levelling) Jarrah. I glued the panel up last week. Its weight adds another 10 kg (22 lbs) to the total, bringing the final weight of the bench to 192 kg or 422 lbs.

I was planing the panel with The Dreadnought (36" Jarrah jointer). The quickest way to flatten I know ...

... using one bench dog and a makeshift stop, when I decided I was going about this in the wrong order. Get the round dog holes done! So I sharpened up a 3/4" Jennings bit and brought out the 12" MF brace ...

I do like this brace. It has the simplicity of a Spofford, but with bling

Soon I had lined up a series of holes opposite the square dogs, each 1" in from the far side of the bench ...

I have chosen to use the brass Veritas dogs. A slight modification is the addition of suede leather on the flat face.

These are long enough to pass through the bench top.

The purpose here is to plane across the bench ...

The bench is now 12" from the far wall. This allows the use of a jointer or jack plane without danger of hitting the wall. It was not possible to work this way when the old bench was attached to the wall.

The new shelf ..

It will hold tools such as a shooting board, Moxon vise, and bench hooks.

Alongside the last two square dogs I added two rows of round dog holes. These are coplanar, enabling a short or long bench stop to span the bench. I have yet to make a couple of stops that will be clamped in the leg vise. The following one was co-opted into use in the short term ...

The leg vise was given a layer of 2mm thick suede leather on each side. This makes a huge difference to the work holding power of the leg vise. It will now clamp pieces securely with little force.

One other point about the leg vise - add the supporting wheels to the glide, as designed by Jameel Abraham, and this will create a smooth running screw, even the wooden one on this bench. I can spin the handle, and the chop will slide in-or-out freely.

My old bench was 34" high. For my height of 5"10" the "pinky test" of Chris Schwarz would point to a bench height of 30" as ideal for planing. My concern, however, was that there are a number of tasks that need to be done at a bench, not just planing. Would the bench be high enough for marking and other detail work? In the end I decided to compromise on a height of 32".

Marking with a gauge is comfortable ...

The Moxon dovetail vise is positioned against a dog, and clamped down by two holdfasts at the rear (which may assitionally be used in any of the round dog holes)..

Marking dovetails is also fine, but sawing is less comfortable at this height than before. The saw has to angle upward and I can feel my wrist having to **** more than I like ..

Cross-cutting (the tails) is another comfortable position ..

A bench hook clamped into the leg vise allows chopping to take place over a leg ...

It has never been this easy to hold work to plane a rebate along an edge ...

I scratched my head for a while how to hold the short ends. Then I remembered I had a tail vise! Easy peasy ..

Finally, the sliding deadman, along with the new Veritas surface clamp, made it easy to hold the completed box for planing ..

So what was the first project being built on the new bench? It will become a tool tray, one that will attach to the wall instead of the bench. I want to leave the edges of the bench free for clamps, if needed. To the tool tray I will add a section to hold a few chisels and backsaws that are in current use. That is for a later date.

The completed bench ...

Regards from Perth

Derek