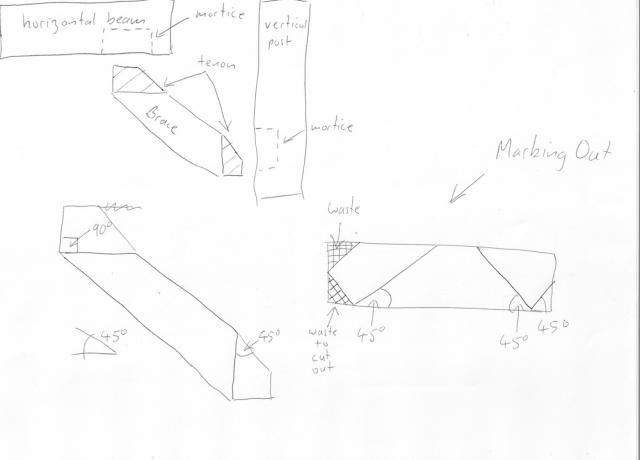

The technique I've used, is to base the angles on the mortice. It's easiest to sink a mortice in at 90 degrees to the face/edge of the beam or post. Hopefully the diagram will give an idea;

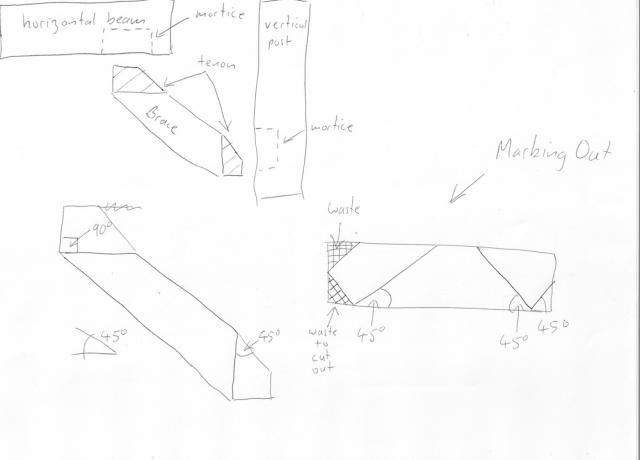

Basically you mark the tenons on the "long side" of the brace with two opposite 45 degree lines. If the mortices are "blind" or "stopped" (don't go all the way through) you need to insert the tenon into the mortice, measure how much sticks out and then cut this off the end of the tenon, plus a mm or two. the end of the tenon doesn't have to match perfectly with the bottom of the mortice, but you don't want to leave too big a gap.

I would also add that I assemble the beam and post first, checking that they are "square", at 90 degrees to each other, and mark the "tenon shoulders" directly from the edges of these, rather than by a bevel or 45degree combination square. Make sure you also mark the beam and post at the same time, where the brace meets them for the mortices. If the beams are coming vertical onto the posts, then insert the brace into the posts first. If the beams go into the posts at assembly, then insert the braces into the beam first. If the braces are going to be pegged, don't drill your holes until after the job is assembled and "squared up" first. You may also want to look up "draw boring" first, if you're going to use pegs.

There are more long winded ways of doing this, such as sinking the mortices at the 45 degree angle into the beams and posts, which is not an easy task, however I think this may weaken the beams and posts more than necessary. The beams and posts need to be the strongest part and the brace can be a lot thinner and considered of secondary importance.

Hope this helps.