Hi, I'm a beginner so apologies if this is a stupid question, but how does one measure a recessed space accurately - for example, the exact distance between the innermost space between 2 rails or aprons? The joinery techniques of folding in a tape measure is only accurate to approx 2 to 3 mil at best and whilst I can measure the outside of the recess with a rule or tape that assumes that the faces I am trying to measure are perfectly parallel which they rarely are especially in joinery. Is there not some kind of expanding ruler that is accurate to a mm at least? I have looked for one but cant see anything suitable and it seems whatever I try is sloppy and leaves me feeling ashamed of my man skills :lol:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to measure a recessed space accurately

- Thread starter glynster

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Mark A

Established Member

I measure a few inches one way, make a little mark, measure the other way and add both together.

bugbear

Established Member

glynster":209pgjp8 said:Hi, I'm a beginner so apologies if this is a stupid question, but how does one measure a recessed space accurately - for example, the exact distance between the innermost space between 2 rails or aprons? The joinery techniques of folding in a tape measure is only accurate to approx 2 to 3 mil at best and whilst I can measure the outside of the recess with a rule or tape that assumes that the faces I am trying to measure are perfectly parallel which they rarely are especially in joinery. Is there not some kind of expanding ruler that is accurate to a mm at least? I have looked for one but cant see anything suitable and it seems whatever I try is sloppy and leaves me feeling ashamed of my man skills :lol:

Pinch rods, then use a normal ruler.

BugBear

Thanks for the tips. I like your idea Mark (no pun intended) proving I marked with a blade I shouldn't get much cumulative error. I dont imagine I could get digital vernier gauges larger enough for my needs. I must admit I have heard of but never understood the "story stick" principle - but sure I would have the same problem in that if would either be too short or too large to fit inside? I will google pinch rods and check that out.

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

Paul Chapman

Established Member

I use the Veritas bar gauge heads http://www.brimarc.com/products/Veritas ... -22795.htm But you could simply use two pieces of wood shorter than the gap and clamp them together with a bulldog clip, or something similar.

They are very useful.

Cheers :wink:

Paul

They are very useful.

Cheers :wink:

Paul

Paul do you use your own sticks for the Veritas bar gauge? Do they have to be exact? I could imagine 2 lengths of dowel being ideal - I'd just need some kind of rudimentary clamp that I could tighten to lock them while I transfer the measurement. I was thinking if I drilled the diameter of the dowels through a small block of wood and then bandsaw cut the block in half along the drill hole lengths, that should remove enough materials and give a profile to provide a strong grip on the dowels when the "sandwich" is clamped - I'd just then need the right screw or clamp - any ideas?

Paul Chapman

Established Member

glynster":2b9lzyx6 said:Paul do you use your own sticks for the Veritas bar gauge?

Yes, you make up your own wooden pieces. I have three sets of different lengths and find them very useful when making shelves and such like. It's worth having something that is easily adjustable because internal spaces are seldom square and you often have to take several measurements. The good thing about having wooden rods is that you can mark them with a pencil and write on them and then re-set the measurements exactly.

If you Google "pinch rods images" there are various examples if you want to make some clamping devices yourself.

Cheers :wink:

Paul

petermillard

Established Member

glynster":7d5oox7r said:I was thinking if I drilled the diameter of the dowels through a small block of wood and then bandsaw cut the block in half along the drill hole lengths, that should remove enough materials and give a profile to provide a strong grip on the dowels when the "sandwich" is clamped - I'd just then need the right screw or clamp - any ideas?

There are tape measures designed specifically for measuring internals - I use a Talmeter and there's one by BMI called a Visio

- also available in Festool green for a slightly higher price

HTH Pete

Edited for clarity

glynster":3vg8jhie said:Hi, I'm a beginner so apologies if this is a stupid question, but how does one measure a recessed space accurately - for example, the exact distance between the innermost space between 2 rails or aprons?

Not the cheapest solution, but probably the easiest - I have one of these http://www.amazon.co.uk/Bosch-DLE40-40m-Laser-Rangefinder/dp/B002LJF7YM

You just hold it against one wall, check the red dot is on the point you want to measure to, and press the button.

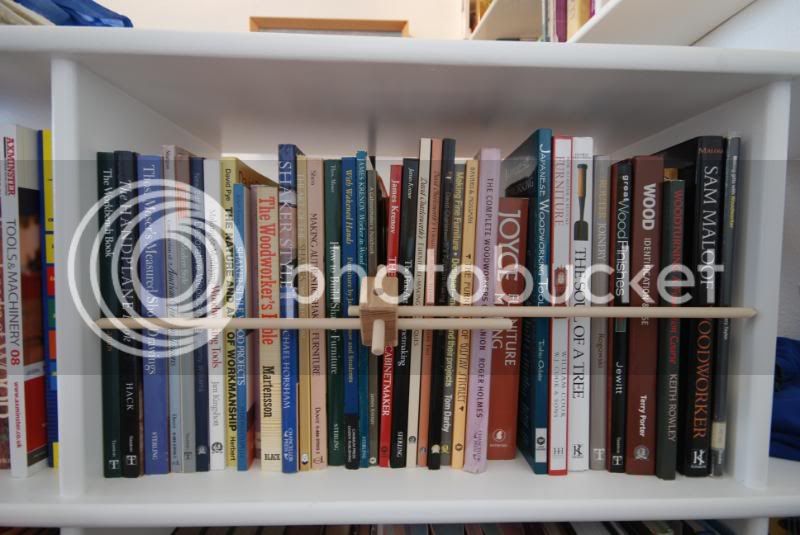

This is what I use - an offcut of plastic mini trunking. The top fits on the base just tight enough to adjust for a snug fit and it cost nothing.

In the picture I am measuring between uprights on a bookcase so I can custom fit a shelf.

In the picture I am measuring between uprights on a bookcase so I can custom fit a shelf.

scholar

Established Member

The above are good tips - I really like the Veritas bar gauge myself (except it has a habit of being too long or too short!).

When I am measuring a recess for say a shelf or countertop, I make up a template with 4 strips of plywood and some corner or bracing pieces which I fix together one corner at a time using hot-melt glue - never fails.

Cheers

When I am measuring a recess for say a shelf or countertop, I make up a template with 4 strips of plywood and some corner or bracing pieces which I fix together one corner at a time using hot-melt glue - never fails.

Cheers

Woodchips2

Established Member

The double glazing surveyors seem to use one of these http://www.buybrandtools.com/acatalog/mEssfix.html but bit expensive if you're not doing a lot of recesses.

Regards Keith

Regards Keith

MMUK

Established Member

The Eriba Turner":1nq2140s said:The double glazing surveyors seem to use one of these http://www.buybrandtools.com/acatalog/mEssfix.html but bit expensive if you're not doing a lot of recesses.

Regards Keith

I've got two of those in different sizes. The 3m one cost me about that but the 6m one cost just shy of £500 :shock:

Thanks, this is fascinating to see and hear of different methods used. I would have though that the problem would have been more common than measuring of shelves etc for those who build with a relative dimensioning methodology.I love the dowel mechanism Pete and it is just the kind of thing I have started thinking about. What are the perpendicular holes in the chock for? How does it lock/fix?

I also like the trunking idea for a cheapo (post-apocolyptic-chic) solution but I'd imagine that it would stick along its track or flex and give a less accurate measure.

I also like the trunking idea for a cheapo (post-apocolyptic-chic) solution but I'd imagine that it would stick along its track or flex and give a less accurate measure.

Mr T

Established Member

Great idea from Andy T. The simple solutions are best!

Chris

Chris

- Joined

- 6 Jun 2011

- Messages

- 2,974

- Reaction score

- 884

petermillard":2i6gv0dr said:glynster":2i6gv0dr said:I was thinking if I drilled the diameter of the dowels through a small block of wood and then bandsaw cut the block in half along the drill hole lengths, that should remove enough materials and give a profile to provide a strong grip on the dowels when the "sandwich" is clamped - I'd just then need the right screw or clamp - any ideas?

There are tape measures designed specifically for measuring internals - I use a Talmeter and there's one by BMI called a Visio

- also available in Festool green for a slightly higher price

HTH Pete

Edited for clarity

We used to stock the BMI Viso tape but can no longer get them so we have replaced them with Richter 3m/10ft Pocket Tape Measure with Sight Window. The same tape but a different colour and cheaper but made in the same factory, we tend to sell them to window fitters, blind makers and to Chrysler USA :!:

Other people buy our WoodPecker Story Sticks but these are more for workshop use.

Cheers Peter

What an interesting thread - I've learnt about some tools I didn't know existed.

It strikes me that there are two different problems here. The difficult one is to make a tool which gives a numerical value, which can be recorded, then used later to make something to the required size. That's what the window measuring tools do.

The other option - which is much simpler - is to make an adjustable stick which is fitted into the space then immediately transferred to the wood that needs to be the same size. This has the advantages that the tool needs no graduation and that you can make the fit as tight or loose as it needs to be. Also, there is no risk of transcription or calculation errors.

I much prefer that way of working whenever possible.

It strikes me that there are two different problems here. The difficult one is to make a tool which gives a numerical value, which can be recorded, then used later to make something to the required size. That's what the window measuring tools do.

The other option - which is much simpler - is to make an adjustable stick which is fitted into the space then immediately transferred to the wood that needs to be the same size. This has the advantages that the tool needs no graduation and that you can make the fit as tight or loose as it needs to be. Also, there is no risk of transcription or calculation errors.

I much prefer that way of working whenever possible.

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 5

- Views

- 2K

- Replies

- 50

- Views

- 8K