Chip shop

Established Member

I have to replace some skirting in a friends gaff. It's only a couple of yards that were terminated by a fitted unit during the original build.

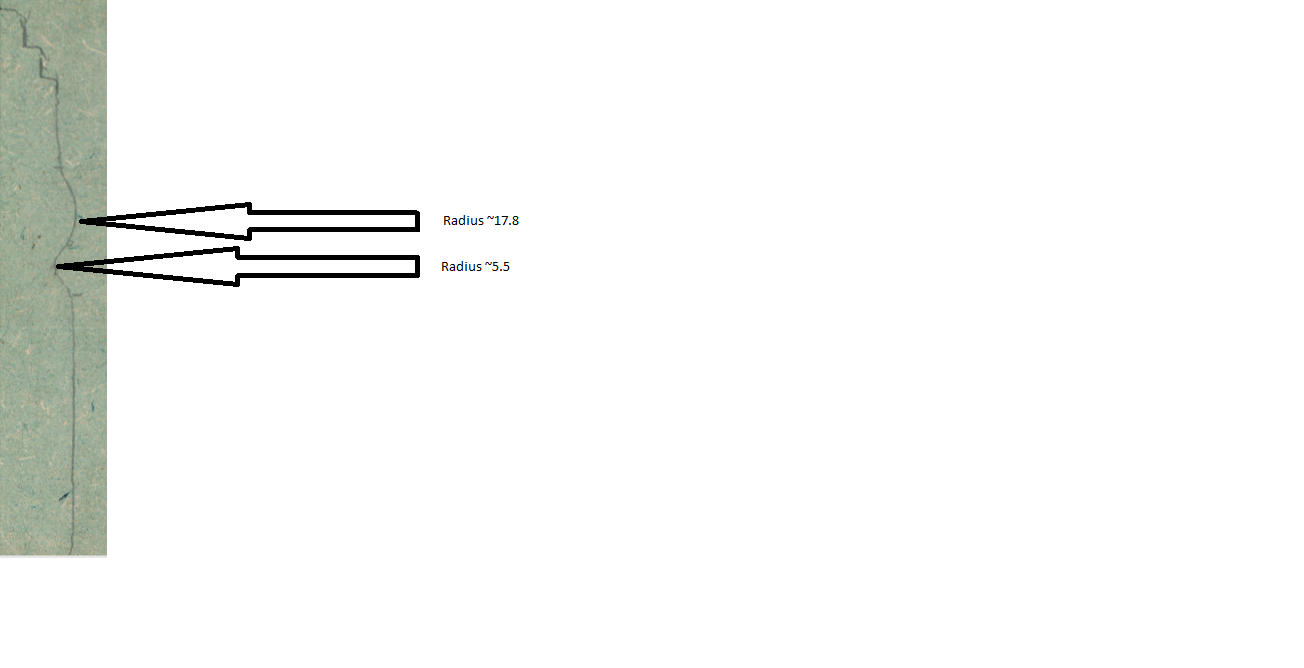

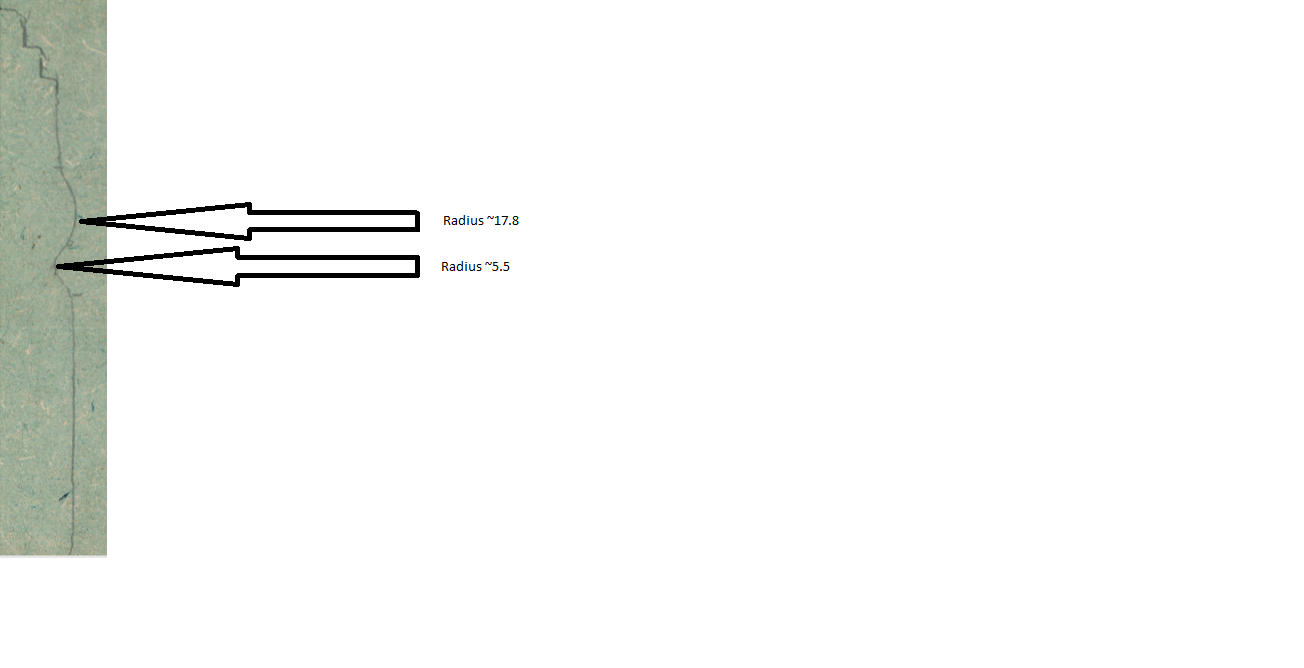

The profile is one I haven't come across before:

I don't want to have knives ground for the spindle as they'd never get used again, and I don't have any blanks to grind my self.

I could do with fitting tomorrow as I have to go over to patch some floor board.

So the question is; how would you lot do it?

Cheers,

Ed

The profile is one I haven't come across before:

I don't want to have knives ground for the spindle as they'd never get used again, and I don't have any blanks to grind my self.

I could do with fitting tomorrow as I have to go over to patch some floor board.

So the question is; how would you lot do it?

Cheers,

Ed