deema":263zg6zg said:

.... Custard’s link to edge jointing is a superb demonstration of the standard techniques taught on how to edge joint.

Except he uses straight edges. Making two edges each fit the straight edge is more difficult than simply fitting them to each other and missing out the straight edge altogether. He also uses the expression "reference face" which is confusing as the term "face" alone is all you need. A board has a (best) face, a back, a (best) edge and back edge. You get them as straight/square as you can first, judging by eye and square, and

then fit them to each other, not to a straight edge.

One thing that isn’t totally clear in the initial question (to me at least) is how the edges are being planed. If the parts are being laid unsupported across the two saw horses then edge jointing will be very difficult.

You couldn't plane an edge on a board simply standing it vertically. How does our OP do it?

The technique illustrated in Custards article shows how long pieces are normally placed on a flat surface that supports it and the planning is done by running the plane alone the flat (reference) surface. Any flat surface when making the work bench will do.

You mean use the bench like a shooting board? Possible I suppose, but tedious. Easier to clamp or wedge them vertically if you don't have a vice. A pair of door props is really handy if you are on site or away from a vice.

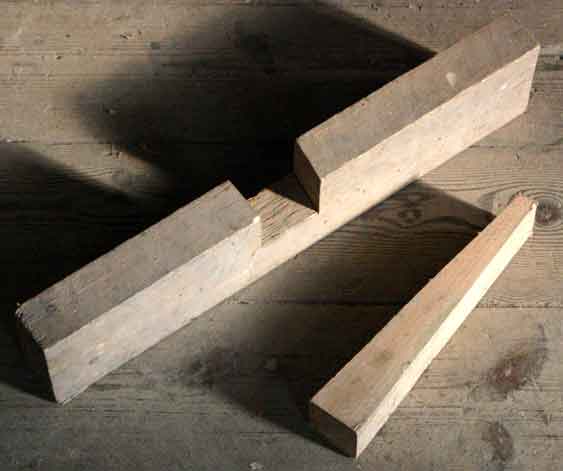

Couldn't find a better photo: these door wedges are knocked up in minutes from scrap, or more carefully on a bench. Brilliant substitute for a bench vice. Stand board in one or two wedge props and put far end of board (door etc to be planed), against something solid for resistance to planing efforts.