Good morning all

I have been making my own workbench. I bought some beechwood and put them in the garage on my sawhorses. I thought it’s a good idea to have them adopting to the room before working on them.

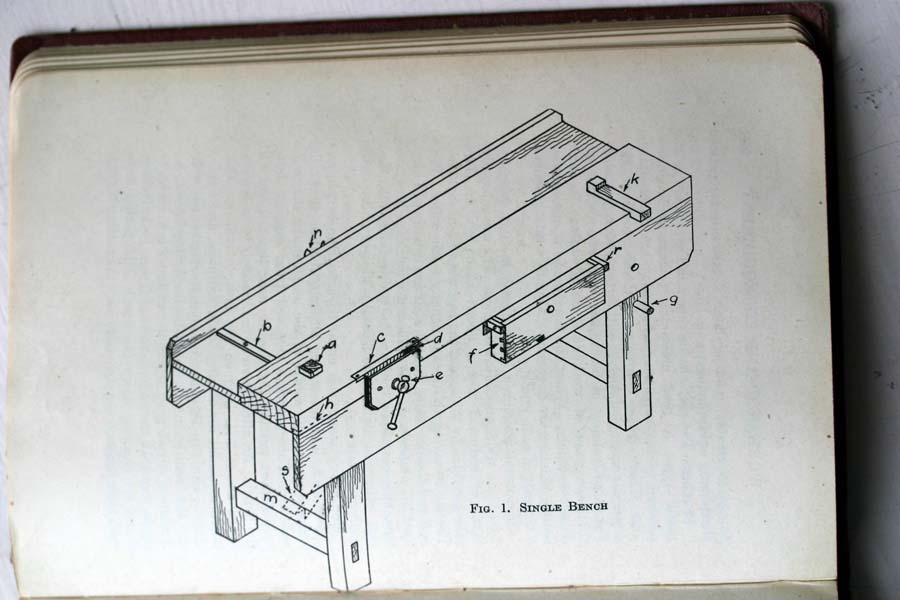

Unfortunately when I picked them up to edge join them there were all sort of bending and bowing in them. I hand planed them and edge join them as per picture.

Last night I put the two halves together to measure for the size of the leg rails. To my surprise there was a gap. It tells me there is still some bump in the middle but I can’t identify it with my 600mm straightedge.

Beside getting a longer straightedge what other ways would you suggest to check and straighten them?

I have been making my own workbench. I bought some beechwood and put them in the garage on my sawhorses. I thought it’s a good idea to have them adopting to the room before working on them.

Unfortunately when I picked them up to edge join them there were all sort of bending and bowing in them. I hand planed them and edge join them as per picture.

Last night I put the two halves together to measure for the size of the leg rails. To my surprise there was a gap. It tells me there is still some bump in the middle but I can’t identify it with my 600mm straightedge.

Beside getting a longer straightedge what other ways would you suggest to check and straighten them?