russ_1380

Established Member

HI,

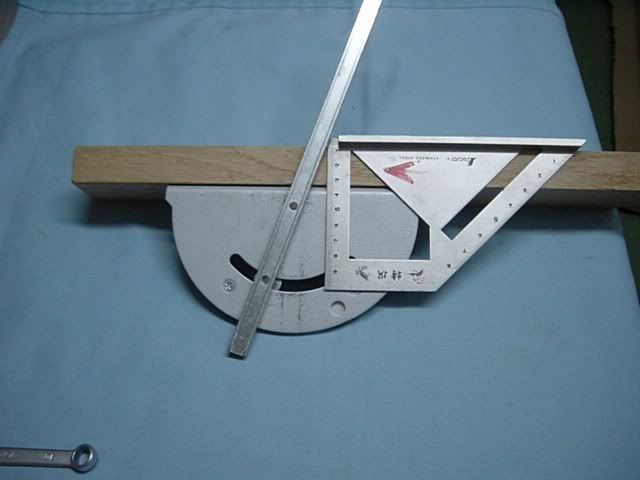

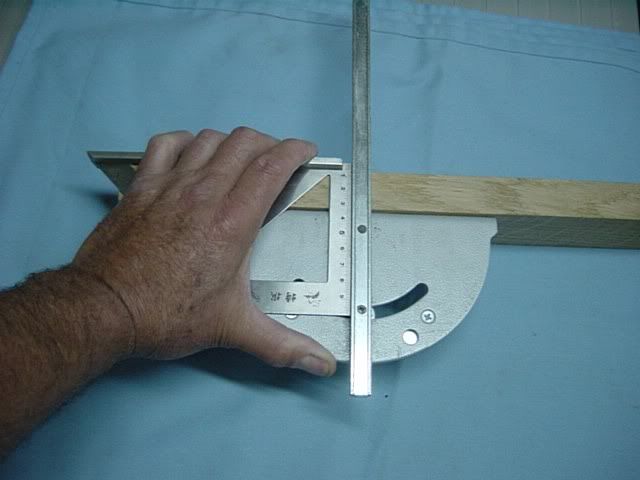

I am cutting some sheet into rectangular panels, I need to ensure they are square (all corners 90 degree).

I recently saw a good web page that showed a simple way to check if your machines fence is accurately set at 90 degrees. (for example; a sled on a table saw where the fence is 90 degrees to the blade, when viewed from above)

Currently I am using the 'measuring the corner to corner technique' , but I can't remember how to do the other technique which I saw.

The technique went something along the lines of:

-Use your fence and make a 90 degree cut o a piece of scrap.

-Cut this piece in half

-Position the two pieces side by side

-Flip one half over

-Align the two pieces together and see if there is a gap

-The gap would then indicate that the pieces were not true 90 degree angles. (Out of square)

I can't really describe it too well, but it was a really simple technique that would show you if the panel was not cut perfectly 90 degrees. Then you could use this to alter the fence angle and try again. With trial and error you can set it so you can make perfect 90 degree cuts.

(Apologies for the poor explanation, I'm hoping someone knows what I'm rattling on about)

Can someone please explain this technique to me?

Cheers

Russ

I am cutting some sheet into rectangular panels, I need to ensure they are square (all corners 90 degree).

I recently saw a good web page that showed a simple way to check if your machines fence is accurately set at 90 degrees. (for example; a sled on a table saw where the fence is 90 degrees to the blade, when viewed from above)

Currently I am using the 'measuring the corner to corner technique' , but I can't remember how to do the other technique which I saw.

The technique went something along the lines of:

-Use your fence and make a 90 degree cut o a piece of scrap.

-Cut this piece in half

-Position the two pieces side by side

-Flip one half over

-Align the two pieces together and see if there is a gap

-The gap would then indicate that the pieces were not true 90 degree angles. (Out of square)

I can't really describe it too well, but it was a really simple technique that would show you if the panel was not cut perfectly 90 degrees. Then you could use this to alter the fence angle and try again. With trial and error you can set it so you can make perfect 90 degree cuts.

(Apologies for the poor explanation, I'm hoping someone knows what I'm rattling on about)

Can someone please explain this technique to me?

Cheers

Russ