tekno.mage

Established Member

Hi guys,

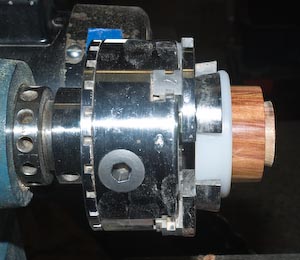

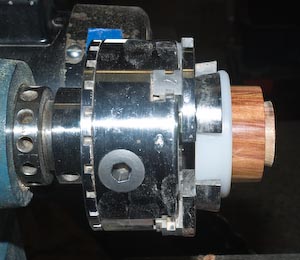

Having been making a number of little boxes recently, I got a little fed up of making a jam chuck to let me finish the bottom of each box - especially as I was having trouble removing the smaller boxes from tightly fitting jam-chucks when I was done (and having to call my partner away from his chiansawing log duties to help with his larger, stronger hands!) So, we put our heads together and came up with these as a solution....

They are made of nylon (turned from solid nylon rod), dovetailed to fit the chuck jaws, then have a gap sawed into them and any sharp inside corners & edges smoothed with some wet'n'dry.

To use, just pop the appropriately sized ring around the flange of the box base, making sure it is snugly pushed up against the shoulder at the base of the flange and insert the whole thing into the chuck. As you tighten the chuck jaws, the ring closes around the box flange and grips securely without marking the flange, allowing the base of the box to be finished. Easy to remove when done and reusable.

Here's some pics of one in use.

Since making these (I so far have a 50mm, 55mm, 59mm & 65mm versions) I've found they can also be used to grip finished lids and bases of straight-sided boxes the other way round (so the inside is accessible) which is great for holding small boxes securely when buffing inside with a domed polishing mop fitted in an electric drill (with the lathe stationary).

The only downside I've found is that they are horrible to make - the nylon swarf winds itself tightly around anything rotating - especially the tail centre and clings to hands and clothes fae worse than wood shavings!

tekno.mage

Having been making a number of little boxes recently, I got a little fed up of making a jam chuck to let me finish the bottom of each box - especially as I was having trouble removing the smaller boxes from tightly fitting jam-chucks when I was done (and having to call my partner away from his chiansawing log duties to help with his larger, stronger hands!) So, we put our heads together and came up with these as a solution....

They are made of nylon (turned from solid nylon rod), dovetailed to fit the chuck jaws, then have a gap sawed into them and any sharp inside corners & edges smoothed with some wet'n'dry.

To use, just pop the appropriately sized ring around the flange of the box base, making sure it is snugly pushed up against the shoulder at the base of the flange and insert the whole thing into the chuck. As you tighten the chuck jaws, the ring closes around the box flange and grips securely without marking the flange, allowing the base of the box to be finished. Easy to remove when done and reusable.

Here's some pics of one in use.

Since making these (I so far have a 50mm, 55mm, 59mm & 65mm versions) I've found they can also be used to grip finished lids and bases of straight-sided boxes the other way round (so the inside is accessible) which is great for holding small boxes securely when buffing inside with a domed polishing mop fitted in an electric drill (with the lathe stationary).

The only downside I've found is that they are horrible to make - the nylon swarf winds itself tightly around anything rotating - especially the tail centre and clings to hands and clothes fae worse than wood shavings!

tekno.mage