manxnorton

Established Member

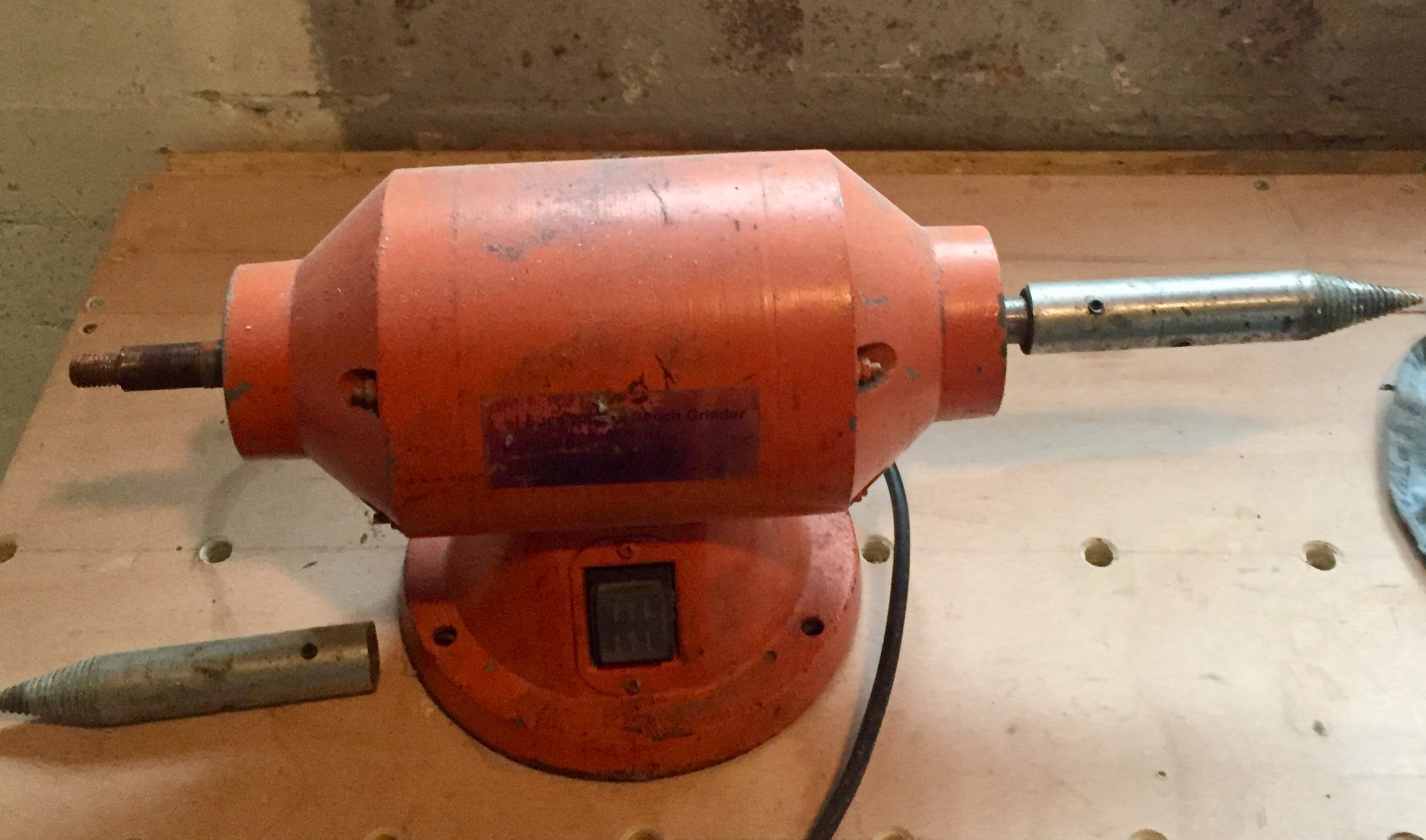

Hi all,

A quick one, I'm going to make a circular sander.

Got the other bits n bobs nearly thought out, apart from one.

could anyone guide me for an attachment to put onto the wheel....if you know what I mean? :lol:

sorry, my brain isn't too good today.

Hope the picture is ok,

Bri

A quick one, I'm going to make a circular sander.

Got the other bits n bobs nearly thought out, apart from one.

could anyone guide me for an attachment to put onto the wheel....if you know what I mean? :lol:

sorry, my brain isn't too good today.

Hope the picture is ok,

Bri