Hello

Newbie here. I would really appreciate some pointers for making the attached design.

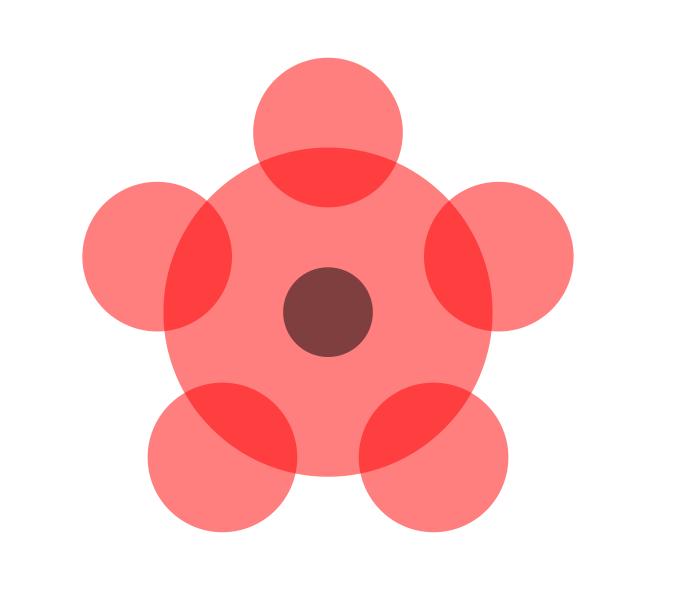

The design is an air valve, a bit like a valve of an internal combustion engine. The valve shaft slides in a 3mm hole in a 20mm solid hard wood board (beech, I think) and covers a 11mm hole on the bottom side. The 11mm hole forks into two 8mm holes, which are 30 degrees off the vertical. I want to make sure that there is about 10mm left of the 3mm hole to guide the valve shaft. The 11mm hole must be clean on the surface to ensure good sealing. The 11mm and 3mm holes must be accurately aligned.

I realise this design might seem a bit awkward, but I have lots of space constraints so even this design took me a bit to come up with.

I'm trying to find the best way to drill the holes. My best attempt is to:

1) drill a 3mm through hole

2) enlarge the 3mm hole to 11mm from the bottom to a small depth using a twist bit

3) drill 8mm holes from the top using a drill guide set at 30 degrees with a brad point bit

I get tear out at where the 8mm holes meet the 11mm hole.

Any better solutions?

I don't yet own a pillar drill but am prepared to get one if it helps.

Thanks in advance.

Newbie here. I would really appreciate some pointers for making the attached design.

The design is an air valve, a bit like a valve of an internal combustion engine. The valve shaft slides in a 3mm hole in a 20mm solid hard wood board (beech, I think) and covers a 11mm hole on the bottom side. The 11mm hole forks into two 8mm holes, which are 30 degrees off the vertical. I want to make sure that there is about 10mm left of the 3mm hole to guide the valve shaft. The 11mm hole must be clean on the surface to ensure good sealing. The 11mm and 3mm holes must be accurately aligned.

I realise this design might seem a bit awkward, but I have lots of space constraints so even this design took me a bit to come up with.

I'm trying to find the best way to drill the holes. My best attempt is to:

1) drill a 3mm through hole

2) enlarge the 3mm hole to 11mm from the bottom to a small depth using a twist bit

3) drill 8mm holes from the top using a drill guide set at 30 degrees with a brad point bit

I get tear out at where the 8mm holes meet the 11mm hole.

Any better solutions?

I don't yet own a pillar drill but am prepared to get one if it helps.

Thanks in advance.