You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Grinding chisels square?

- Thread starter J_SAMa

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Jacob

What goes around comes around.

No it's quite true.phil.p":3q55soyo said:... a hollow ground bevel is easy to hone" ....this is heresy - ....

But it's not good for the tool - it weakens the edge (less metal behind it) and strong risk of overheating. It's just a quick way or removing metal, good for reshaping/repairing nicked edges etc, favoured by school kids in the woodwork class but generally deprecated for sharpening.

Fromey

Established Member

I think you can take hollow grinding in two ways. i) you hone only the cutting edge forward of the hollow and ii) you grind/hone down both the forward and behind sections, relative to the hollow, until you get a full flat bevel. Both i) and ii) provide some time savings, especially is you've started with a chipped or skewed blade, as Jacob says.

I suppose i) could technically lead to relative weakness behind the edge. The weakest point would be at the hollow's lowest point (i.e, the shortest distance from the back of the blade to hollow. However, the hollows you get from any typical bench grinder are extremely shallow and well back from the cutting edge. I can't see you ever snapping the blade through at that point! It's still many millimetres of steel. To do that, you'd have already disintegrated the handle of the chisel from your mighty Thor-like blow. Further, if you've put such a large secondary bevel on the blade such that it extends that far back to make the hollow a true weak point, it would be one mad chisel and you would have re-established the primary bevel long ago. Thus, I don't see this method weakening a blade operationally.

I suppose i) could technically lead to relative weakness behind the edge. The weakest point would be at the hollow's lowest point (i.e, the shortest distance from the back of the blade to hollow. However, the hollows you get from any typical bench grinder are extremely shallow and well back from the cutting edge. I can't see you ever snapping the blade through at that point! It's still many millimetres of steel. To do that, you'd have already disintegrated the handle of the chisel from your mighty Thor-like blow. Further, if you've put such a large secondary bevel on the blade such that it extends that far back to make the hollow a true weak point, it would be one mad chisel and you would have re-established the primary bevel long ago. Thus, I don't see this method weakening a blade operationally.

GazPal

Established Member

Fromey":3jkzzk0x said:I think you can take hollow grinding in two ways. i) you hone only the cutting edge forward of the hollow and ii) you grind/hone down both the forward and behind sections, relative to the hollow, until you get a full flat bevel. Both i) and ii) provide some time savings, especially is you've started with a chipped or skewed blade, as Jacob says.

I suppose i) could technically lead to relative weakness behind the edge. The weakest point would be at the hollow's lowest point (i.e, the shortest distance from the back of the blade to hollow. However, the hollows you get from any typical bench grinder are extremely shallow and well back from the cutting edge. I can't see you ever snapping the blade through at that point! It's still many millimetres of steel. To do that, you'd have already disintegrated the handle of the chisel from your mighty Thor-like blow. Further, if you've put such a large secondary bevel on the blade such that it extends that far back to make the hollow a true weak point, it would be one mad chisel and you would have re-established the primary bevel long ago. Thus, I don't see this method weakening a blade operationally.

Bends and breaks do happen and most typically when using hollow ground blades where they're ground with too shallow a primary bevel.

bugbear

Established Member

GazPal":tz3ljsm2 said:Bends and breaks do happen and most typically when using hollow ground blades where they're ground with too shallow a primary bevel.

There's an obvious distinction between "hollow grinding" and "too hollow grinding". The former is a viable technique, the latter is (definitively) an error.

BugBear

GazPal

Established Member

bugbear":23bdto1j said:GazPal":23bdto1j said:Bends and breaks do happen and most typically when using hollow ground blades where they're ground with too shallow a primary bevel.

There's an obvious distinction between "hollow grinding" and "too hollow grinding". The former is a viable technique, the latter is (definitively) an error.

BugBear

I'm in agreement to a degree, but think beginners lack sufficient information for them to know how much hollow grind is too much and whether of not to focus a hollow grind toward the rear, or centrally on the bevel and how to allow for the reduction created when hollow grinding/forming a primary bevel angle. Obvious to those of us with sufficient experience, but not for newcomers.

It's all well and good telling others that a hollow grind is the way to go and I'm a great believer in it's correct use, but potential down sides exist:

i) It's impossible to hollow grind without a bench grinder.

ii) Less than an 8" diameter grinding wheel tends to result in an overly deep hollow grind.

iii) Hollow grinding naturally reduces the intermediate ground surface below the target angle.

iv) The risk of drawing a tool's temper via overheating is high when grinding is done by inexperienced hands.

The manner in which I was taught to sharpen erred on the side of craft operations carried out by hand and with little to no reliance upon power tools/tooling. Learning longhand before shorthand. It's often a more physically demanding route, but teaches the pupil the "long way" about craft practices & solutions, whilst enhancing skill & technique development. Once a skill is mastered - like all skills - it is seldom lost and can easily be filed to the back of one's mind for re-use at times when mechanised aids fail. Many present day craftsmen have - at no fault of their own - been taught the shorthand (Power tool) route and now lack the dexterity afforded within their craft/trade by mastery of the hand tools potentially available to them.

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£239.99

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

custard

Established Member

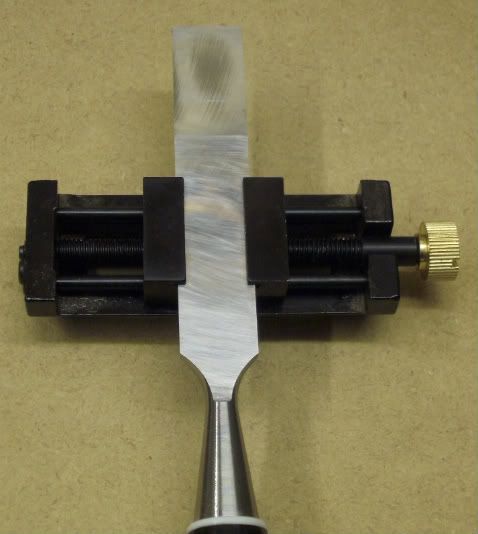

Richard Kell's honing guides are great for chisels, because they reference from the face. But...(there's always a "but" with honing guides!) they can't deliver the steeper angles you'd need for striking chisels, Japanese chisels, or A2 steel, in that case you'd need to make a little perspex platform that sits on your stone and supports the jig wheels, with a cutout out for the chisel to reach the stone. It's not a big deal, and the Kell guides pretty much guarantee square edges, but only you can decide if it's worth the hassle.

bugbear

Established Member

custard":3drf7elt said:Richard Kell's honing guides are great for chisels, because they reference from the face.

I''ll just point out, they're far from the only ones that reference the back, including the Veritas mk II.

BugBear

custard

Established Member

bugbear":1q8h3e4a said:custard":1q8h3e4a said:Richard Kell's honing guides are great for chisels, because they reference from the face.

I''ll just point out, they're far from the only ones that reference the back, including the Veritas mk II.

BugBear

Yes, the Veritas does indeed register from the "cutting" face (I don't know if that's properly called the front or the back). But it then clamps from the opposite "non cutting" face, and consequently it's all too easy to twist the chisel and end up honing out of square. The Kell guide registers from the cutting face, and then clamps from the edges, so there's no tendency to twist the chisel out of registration. The real problem with the Kell guide (besides the inherent faff in using a honing guide on a chisel, where I find I want to be touching up the edge too frequently to make any honing guide worthwhile) is that it won't hone at steeper angles without the perspex jig that I previously mentioned.

Paul Chapman

Established Member

custard":1cicuswy said:The Kell guide registers from the cutting face, and then clamps from the edges, so there's no tendency to twist the chisel out of registration.

So does the Trend

Which also has a wide roller, which is good for chisels

Mind you, the Eclipse-style also registers from the back if you modify it

Cheers :wink:

Paul

David C

In Memorium

Paul,

What a fine modification ~;-)#

David

What a fine modification ~;-)#

David

bugbear

Established Member

Paul Chapman":xjmldobp said:

Cough. Good for narrow chisels. Anything wider than around 3/4" will self-register on the abrasive.

BugBear

David C

In Memorium

Perfecting squareness of most chisels (except the very narrow) can be done with the Eclipse guide.

A forefinger is placed on each side of the blade, near the tip. If more force is used on the 'long' side, as one works on a coarse stone, the edge will become squarer with each stroke.

(I am assuming something like 800 grit waterstone, at about 30 degrees, on a chisel which has been ground at 25 degrees).

best wishes,

David

A forefinger is placed on each side of the blade, near the tip. If more force is used on the 'long' side, as one works on a coarse stone, the edge will become squarer with each stroke.

(I am assuming something like 800 grit waterstone, at about 30 degrees, on a chisel which has been ground at 25 degrees).

best wishes,

David

Jacob

What goes around comes around.

You don't particularly need perfect squareness. If it's off a bit just make a mental note to correct it next time you sharpen, and/or the time after that. Narrow chisels are really easy to do freehand (less metal to remove) - pull towards instead of pushing.

Similar threads

- Replies

- 17

- Views

- 1K