RogerS

Established Member

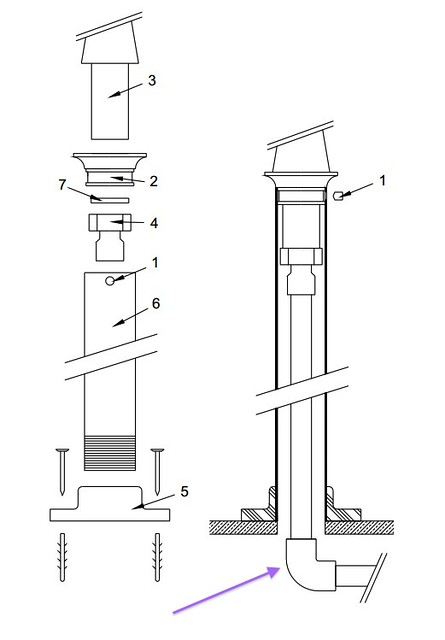

I admit defeat! I can't see how this can be done without ripping down the ceiling underneath. But there must be a way surely but how? Need to fit a pair of standpipe shrouds similar to these

What is foxing me is how you make the bottom connection (arrowed). Options are:

1) Copper right angle and solder? But the length of those elbows means it will hardly appear above the tiling. I'll be blasting a flame straight at the underlying ply supporting substrate...surely not a good idea.

2) Ditto compression join. The elbow is going to be too short to stick above the tiles to get a spanner on. Or are there special elbows with long legs designed for this?

3) Hep2O push-fit.....how to get support underneath the elbow to resist the downward pressure as you push the vertical pipe in. Can't see how.

4) Remove ceiling in room below.

Not helped by SWMBO saying 'shouldn't we get someone in'....grrrrrrrr :evil:

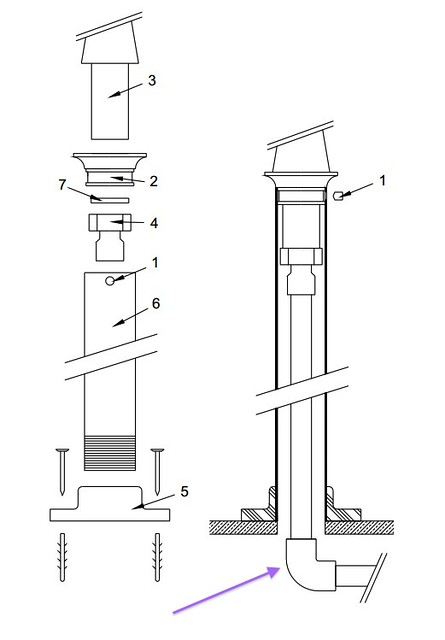

What is foxing me is how you make the bottom connection (arrowed). Options are:

1) Copper right angle and solder? But the length of those elbows means it will hardly appear above the tiling. I'll be blasting a flame straight at the underlying ply supporting substrate...surely not a good idea.

2) Ditto compression join. The elbow is going to be too short to stick above the tiles to get a spanner on. Or are there special elbows with long legs designed for this?

3) Hep2O push-fit.....how to get support underneath the elbow to resist the downward pressure as you push the vertical pipe in. Can't see how.

4) Remove ceiling in room below.

Not helped by SWMBO saying 'shouldn't we get someone in'....grrrrrrrr :evil: