seanybaby

Established Member

I recently started making my first chair. It's a pretty simple design made in Oak.

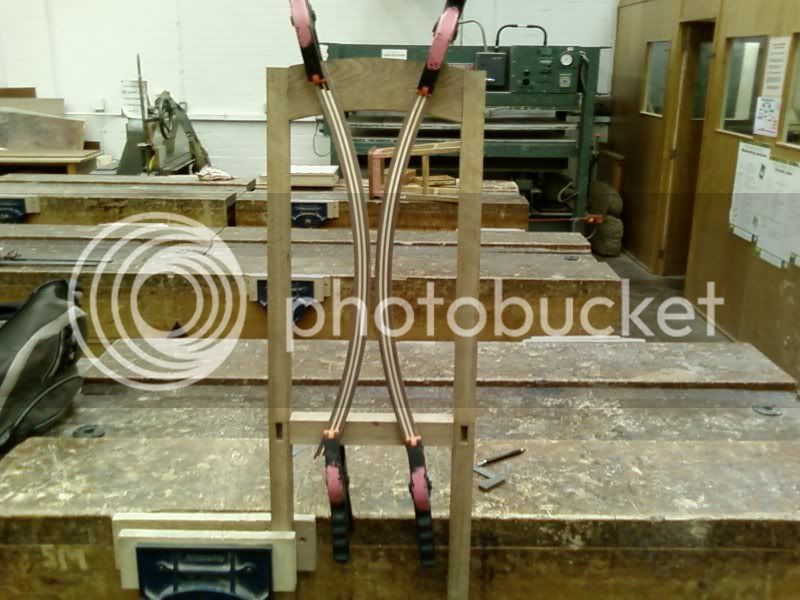

Back legs and rails, which will be glued up next week when i finish the curved slats.

Front legs have been glued up with a rebate for seat.

Rails with angled tenons and rebates for the seat. The first one i cut was miles out, so i had to glue a little veneer to pack it out. The rest of them fitted much better. However all the shoulders will need tweaking before glueing up.

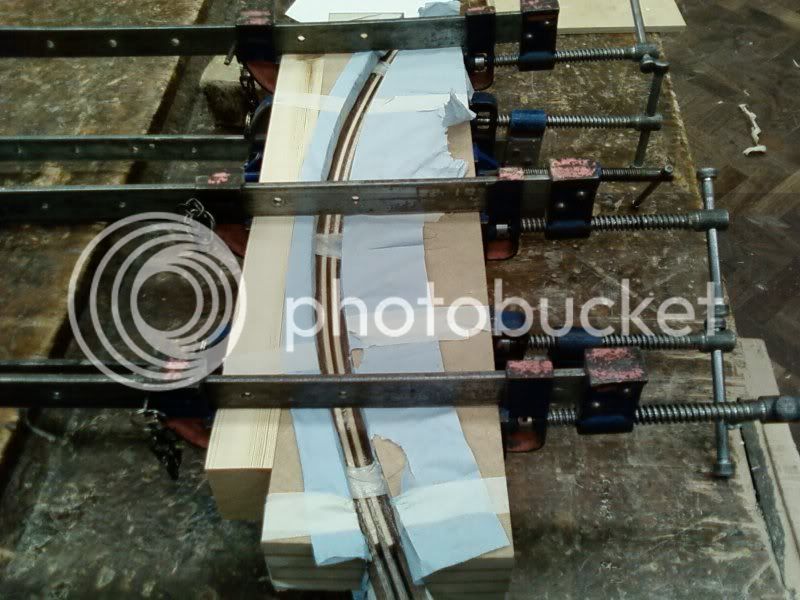

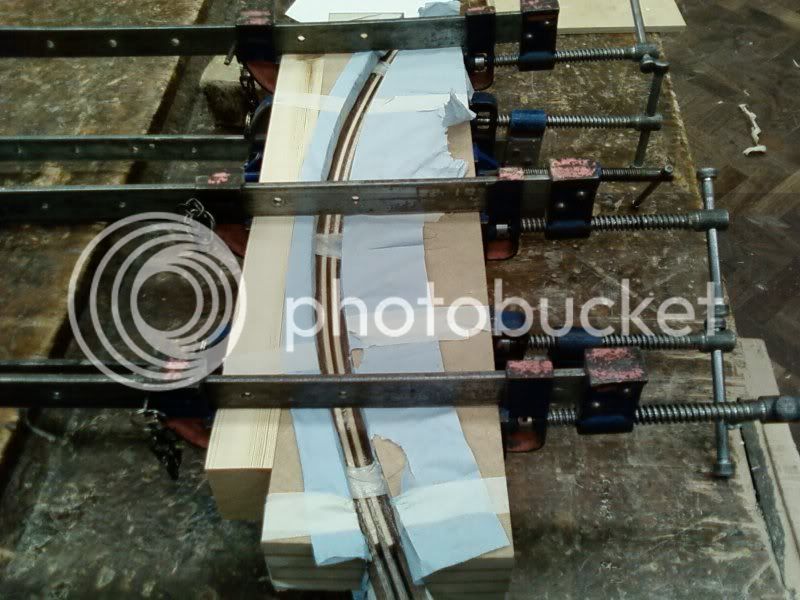

It took a while to decide on the design for the back. I wanted to a technique, i've not really used so decided i would have a go at laminating. A rod was drawn up for the back.

For the back i chose Walnut with 2 Sycamore srtipes. I made a former using MDF and glued up with cascamite.

Next week i hope to get the whole chair glued up and the corner blocks in.

Back legs and rails, which will be glued up next week when i finish the curved slats.

Front legs have been glued up with a rebate for seat.

Rails with angled tenons and rebates for the seat. The first one i cut was miles out, so i had to glue a little veneer to pack it out. The rest of them fitted much better. However all the shoulders will need tweaking before glueing up.

It took a while to decide on the design for the back. I wanted to a technique, i've not really used so decided i would have a go at laminating. A rod was drawn up for the back.

For the back i chose Walnut with 2 Sycamore srtipes. I made a former using MDF and glued up with cascamite.

Next week i hope to get the whole chair glued up and the corner blocks in.