I was just curious as to the consensus on the best plane to use solely for finishing. I've not a great deal of experience with all the many permutations of blade angle, bevel direction etc. I'm thinking along high angle, 60 to 95 degrees (plus?) sort of lines.... What would you guys recommend?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Finishing Plane...

- Thread starter SteveJ

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Philly

Established Member

Steve

For a dedicated finishing plane you need a tight mouth, a high angle if you work timber with interlocked or tricky grain, and a sharp blade.

For bed angle I would recommend 55 to 60 degrees - any less isn't effective for interlocked grain, any high er and the plane becomes uncomfortable to push (and you get accelerated blade wear).

Hope this helps with your decision making,

Cheers

Philly

For a dedicated finishing plane you need a tight mouth, a high angle if you work timber with interlocked or tricky grain, and a sharp blade.

For bed angle I would recommend 55 to 60 degrees - any less isn't effective for interlocked grain, any high er and the plane becomes uncomfortable to push (and you get accelerated blade wear).

Hope this helps with your decision making,

Cheers

Philly

Steve,

Don't overlook the attributes of a bevel up plane. The Veritas low angle smoother is a superb plane.

http://www.classichandtools.com/acatalog/New_Bevel_Up.html

I would recommend this plane, which is well liked in these here parts (excluding Essex) :wink: :lol:

Cheers, Tony.

Don't overlook the attributes of a bevel up plane. The Veritas low angle smoother is a superb plane.

http://www.classichandtools.com/acatalog/New_Bevel_Up.html

I would recommend this plane, which is well liked in these here parts (excluding Essex) :wink: :lol:

Cheers, Tony.

bugbear

Established Member

Philly":ip568ocq said:Steve

For a dedicated finishing plane you need a tight mouth, a high angle if you work timber with interlocked or tricky grain, and a sharp blade.

For bed angle I would recommend 55 to 60 degrees - any less isn't effective for interlocked grain, any high er and the plane becomes uncomfortable to push (and you get accelerated blade wear).

You also get an increasingly poor surface :-(

A lower cutting angle gives a better cut. So it's a compromise between "general" surface quality, and avoiding tearout.

BugBear

woodbloke

Established Member

Hi Tony - nicely done :lol: :lol: :lol: - RobEscudo":z32er7oy said:(excluding Essex) :wink: :lol:

Cheers, Tony.

£49.91

£58.33

Mefape Mortise and Tenon Jig Tools for Woodworking Routers, Tenon Cutter, Manual Mortising Machine, Invisible Slotting Machine Jig Stand, 3-Axis Guide Rail for Adjust Trimming Length and Width

wangshijuntianjinhongyuegongyipin

£9.99 (£1.00 / count)

£14.45 (£1.44 / count)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£16.99

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£10.10

£15.48

Portwest Browguard with Clear Visor, Size: One Size, Colour: Clear, PW91CLR

Amazon.co.uk

£15.99 (£1.60 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£199.00

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£10.19 (£0.39 / count)

£11.99 (£0.46 / count)

Nicpro Carpenter Pencil with Sharpener, Mechanical Carpenter Pencils Set with 26 Refills, Case, Deep Hole Marker Construction Pencils Heavy Duty Woodworking Pencils for Architect (Black, Red)

NicproShop EU

£34.99 (£3.50 / count)

£39.99 (£4.00 / count)

VonHaus Chisel Set - 10pcs Woodworking Tools Set - Wood Carving Tools, Wood Chisel Sets with Sharpening Stone, Honing Guide and Storage Case

VonHaus UK

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

Philly

Established Member

You'll get a superior finish with a plane, so plane when possible. Scrape when cornered :lol:

Hope this helps

Philly

Hope this helps

Philly

A

Anonymous

Guest

Steve

Many seem to like the bevel up smoothers (possibly they have not tried a good quality bevel down smoother), I have the LV and it is a nice plane, but my 4.5s are generally much better smoothers (I use a 10 degree back bevel on one of them and standard angle on the other) and no wood has defeated them thus far.

The BU planes are easier to adjust the cutting angle (back bevels are easy to apply too) but they are a little light and tend to ride and skit over the surface if the blade is not razor sharp.

I find I have to sharpen the BU plane at least twice as often as the bevel down 4.5.

For the record, I really like my LV BU smoother and tend to use it on end grain.

How about a custom made Philly Plane with high angle? I have one and it is superb!

Many seem to like the bevel up smoothers (possibly they have not tried a good quality bevel down smoother), I have the LV and it is a nice plane, but my 4.5s are generally much better smoothers (I use a 10 degree back bevel on one of them and standard angle on the other) and no wood has defeated them thus far.

The BU planes are easier to adjust the cutting angle (back bevels are easy to apply too) but they are a little light and tend to ride and skit over the surface if the blade is not razor sharp.

I find I have to sharpen the BU plane at least twice as often as the bevel down 4.5.

For the record, I really like my LV BU smoother and tend to use it on end grain.

How about a custom made Philly Plane with high angle? I have one and it is superb!

woodbloke

Established Member

At West Dean '08 I presented the LN demonstrator with a lump of stuff that was almost impossible :evil: :evil: to plane. Out of all the LN planes on his bench (and he had the lot) he picked a low angle jack to do the job, with an effective pitch of 62deg - Rob

Mikey R

Established Member

woodbloke":32dz8d1z said:At West Dean '08 I presented the LN demonstrator with a lump of stuff that was almost impossible :evil: :evil: to plane. Out of all the LN planes on his bench (and he had the lot) he picked a low angle jack to do the job, with an effective pitch of 62deg - Rob

That may have been because he had already demonstrated the rest, and wanted to try and sell you a BU as well.

Whoa.. so many choices  Alas a philly plane or any high-end commercial plane are out of my reach right now, too few pennies

Alas a philly plane or any high-end commercial plane are out of my reach right now, too few pennies

I have a bevel-up Stanley block (220A if memory serves) which I love to bits, and I've just finished refurbing an Anat 4B (will have to get pics sorted) which I picked up at a car boot for the princely sum of £1.50 I've another number four, a very cheap nasty lil thing off of ebay that I'm hatching plans to 'modify', will try going down the back-bevel route and see what I end up with. I'm also expecting a delivery from Rutlands this week - a small Dakota Hong-Kong stylie plane with a 60 degree bed that I'm eager to test drive... One way or another I'll get the bases covered

I've another number four, a very cheap nasty lil thing off of ebay that I'm hatching plans to 'modify', will try going down the back-bevel route and see what I end up with. I'm also expecting a delivery from Rutlands this week - a small Dakota Hong-Kong stylie plane with a 60 degree bed that I'm eager to test drive... One way or another I'll get the bases covered

I have a bevel-up Stanley block (220A if memory serves) which I love to bits, and I've just finished refurbing an Anat 4B (will have to get pics sorted) which I picked up at a car boot for the princely sum of £1.50

woodbloke

Established Member

There was no overt or even covert selling involved, this was a bit of a gauntlet thing as the timber concerned was the 'Wood from Hell' - RobMikey R":27eso1vi said:woodbloke":27eso1vi said:At West Dean '08 I presented the LN demonstrator with a lump of stuff that was almost impossible :evil: :evil: to plane. Out of all the LN planes on his bench (and he had the lot) he picked a low angle jack to do the job, with an effective pitch of 62deg - Rob

That may have been because he had already demonstrated the rest, and wanted to try and sell you a BU as well.

SteveJ":zhmwy08r said:Alas a philly plane or any high-end commercial plane are out of my reach right now, too few pennies

Resistance to The Slope is futile.....

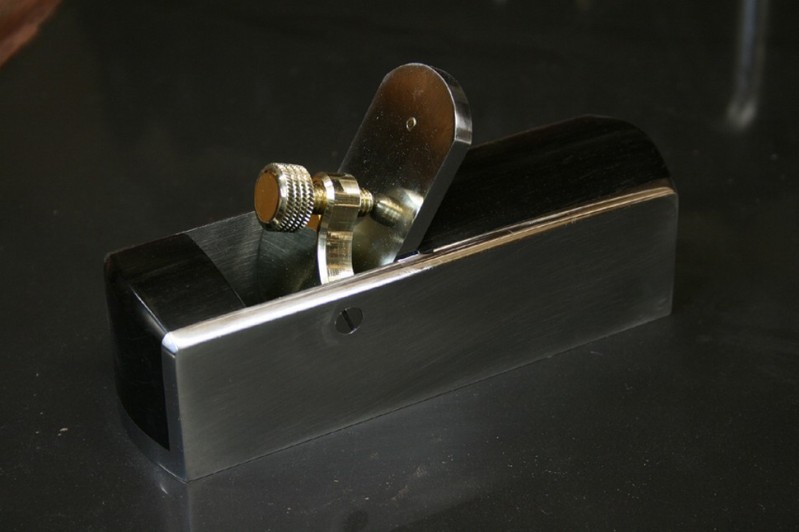

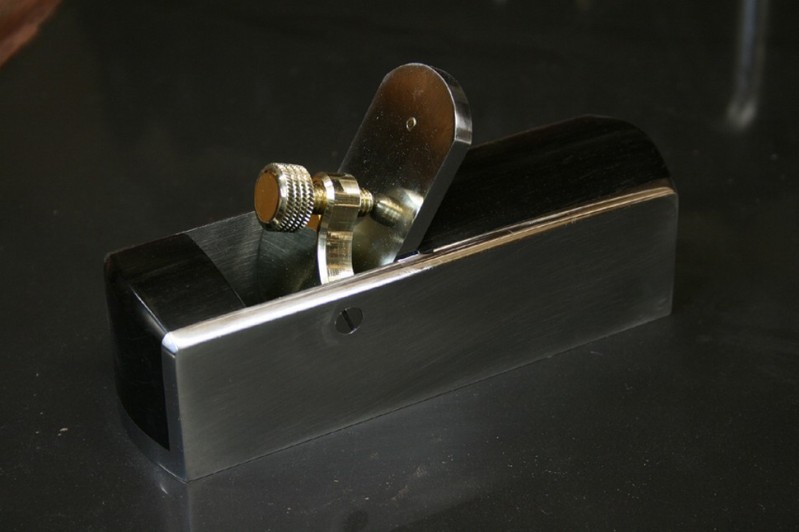

This Philly smoother is a cracker - and doubles as a scraper plane by simply reversing the blade.

Cheers

Karl

Derek Cohen (Perth Oz)

Established Member

Philly wrote:

High cutting angles are pretty much the norm for me on interlinked grain. You can basically use anything on straight grained timber. Uncomplicated soft woods benefit from a lower cutting angle. These can leave a polished look that one does not wish to finish further!

For high cutting angles up and including 60 degrees, I will use both BU and BD planes. However the BU planes, with their lower centre of effort, work these high angles more easily (less effort) than BD planes. I will take the BU planes to 65 degrees and they will plane as effortlessly as a BD plane that is 10 degrees lower.

Here's my newest BD high angle smoother: Ron Brese made up a custom kit for me ... 60 degree bed, all-steel body. I infilled it with ebony, and added a few personal touches to the design. http://www.inthewoodshop.com/ToolReviews/TheBreseSmallSmootherKit.html

This is a small plane, based on Karl Holtey’s 11-S, and just 6 1/2" in length.

Regards from Perth

Derek

For bed angle I would recommend 55 to 60 degrees - any less isn't effective for interlocked grain, any high er and the plane becomes uncomfortable to push (and you get accelerated blade wear).

High cutting angles are pretty much the norm for me on interlinked grain. You can basically use anything on straight grained timber. Uncomplicated soft woods benefit from a lower cutting angle. These can leave a polished look that one does not wish to finish further!

For high cutting angles up and including 60 degrees, I will use both BU and BD planes. However the BU planes, with their lower centre of effort, work these high angles more easily (less effort) than BD planes. I will take the BU planes to 65 degrees and they will plane as effortlessly as a BD plane that is 10 degrees lower.

Here's my newest BD high angle smoother: Ron Brese made up a custom kit for me ... 60 degree bed, all-steel body. I infilled it with ebony, and added a few personal touches to the design. http://www.inthewoodshop.com/ToolReviews/TheBreseSmallSmootherKit.html

This is a small plane, based on Karl Holtey’s 11-S, and just 6 1/2" in length.

Regards from Perth

Derek

ac445ab

Established Member

Hi,

This is my solution for smoothing planes:

I modified ordinary BD planes (Stanley 3, 4 and Record 4 1/2) by adding a thicker blade from woodies. Cutting angle is 55° (10° back bevel).

Ciao,

Giuliano

This is my solution for smoothing planes:

I modified ordinary BD planes (Stanley 3, 4 and Record 4 1/2) by adding a thicker blade from woodies. Cutting angle is 55° (10° back bevel).

Ciao,

Giuliano

Vann

Established Member

Of course Lee Valley like to confuse people - that link is to their Bevel Up Smoother. Their Low Angle Smoother is a little different.Escudo":3r1x4szx said:The Veritas low angle smoother is a superb plane.

http://www.classichandtools.com/acatalog/New_Bevel_Up.html

e.g. BUS 2¼" iron - LAV 2" iron. etc.

Cheers, Vann.

bugbear

Established Member

woodbloke":1no0uu5j said:There was no overt or even covert selling involved, this was a bit of a gauntlet thing as the timber concerned was the 'Wood from Hell' - RobMikey R":1no0uu5j said:woodbloke":1no0uu5j said:At West Dean '08 I presented the LN demonstrator with a lump of stuff that was almost impossible :evil: :evil: to plane. Out of all the LN planes on his bench (and he had the lot) he picked a low angle jack to do the job, with an effective pitch of 62deg - Rob

That may have been because he had already demonstrated the rest, and wanted to try and sell you a BU as well.

I'd call that subtle selling of the first order

BugBear

Modernist

Established Member

Addressing the original question would a BU plane not be the most versatile as I have found with my LN62 using 30 and 45 degree blades. With that extra £30 you can smooth, shoot and high angle difficult grain. I haven't used my LV scraper since I bought it owing to the superior finish from the plane.

Similar threads

- Replies

- 4

- Views

- 797

- Replies

- 16

- Views

- 2K

- Replies

- 5

- Views

- 252

- Replies

- 3

- Views

- 2K