ScaredyCat

Established Member

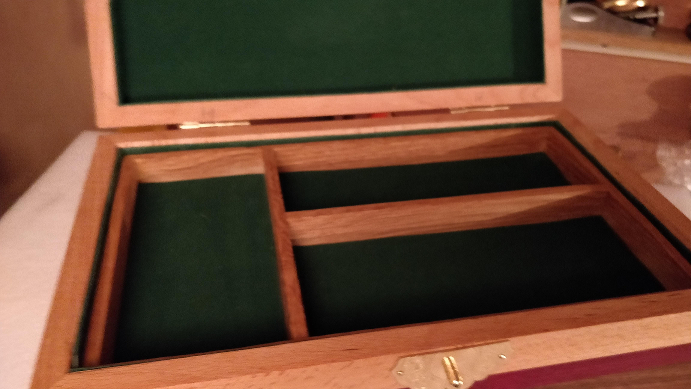

I'm making a box and my intention is to line it. for the finish I was thinking of boiled linseed oil and then beeswax polish buffed up to a sheen. I know that I need to finish before lining.

I have a test piece that I'm using to look at how the blo works out, but as you can see (and probably already know) it gets sucked into the wood. This means that on the side I want to put the lining I'm getting linseed oil. I suspect this will affect any adhesion - can someone let me know if this is going to be an issue? Are there other, comparible finishes that'll give the same effect but not cause lining issues?

Also, what's the expected drying time of blo? I put some on last night and it was still a little oily this morning.

I have a test piece that I'm using to look at how the blo works out, but as you can see (and probably already know) it gets sucked into the wood. This means that on the side I want to put the lining I'm getting linseed oil. I suspect this will affect any adhesion - can someone let me know if this is going to be an issue? Are there other, comparible finishes that'll give the same effect but not cause lining issues?

Also, what's the expected drying time of blo? I put some on last night and it was still a little oily this morning.