Mornin' JT.

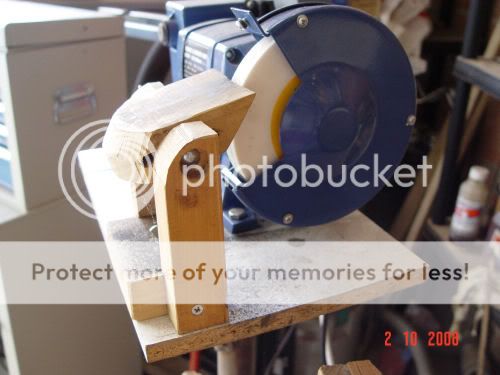

IMO this is one of the best designs of jig. This and a flat table will do all the sharpening you can ever wish for. I would go ahead, better the Perform gouge than a better one later.

The way I, and many others start preparing a gouge for long wings is as follows.

I don't measure my wings, what I do is grind them so the side edge is approx 1 1/2 times the width of the tool. So make a mark with a felt tip this distance from the tip.

Using a flat table place the gouge flute down and adjust the table so as you can grind the corners off between the mark and the bottom of the flute. (Which is now uppermost)

Gently grind away until you just reach the bottom of the flute, try not to take any more, it won't do any harm just means you grind away more steel than needed. You should now have a almost flat angle on both sides between you felt tip mark and the tip of the tool.

When you look down on the top of the tool you should now have a elipse? shape on each side of the flute. The inner edge of these flats is where the edges of your wings will come to.

Once you have made your swept wing jig, fit the gouge into it, set the nose of the tool to the wheel at the angle you fancy. Nothing too critical here. Then slowly grind a little on the nose swinging the tool slightly from side to side with just light pressure.

Once you have the shape of the tip, now swing the jig right to the side and begin working on the sides. DON'T swing the jig from right to left, all you are doing is working on one side at a time, just roll the tool following the inner edge of your line. Grind a bit on one side staying outside the inner edge of the flat.

As each side heats up from the grinding, swing the jig around and work for some time on the other side. Alternate like this until you have a shape corresponding to the inner edge of the flats.

Once you have your your full shape now is the time to swing the tool from side to side, very gently. Until you see a complete edge from one side to the other. Be careful on the tip it is very easy to grind too much away here.

That's it! Just be careful in use, these grinds are great but can be a bit vicious if your not used to them.

:idea: Another tip is drill a hole approx. 2" deep in a wood block, and use this to set the tip overhang each time you sharpen the gouge, this way it saves you wasting steel. Also you can make a sizing stick to mark how far your arm is away from the wheel, so it saves you even having to measure this each time also.

I guess from this you have figured I'm a lazy b****r, I prefer to call it efficient. :lol: :lol: :lol: