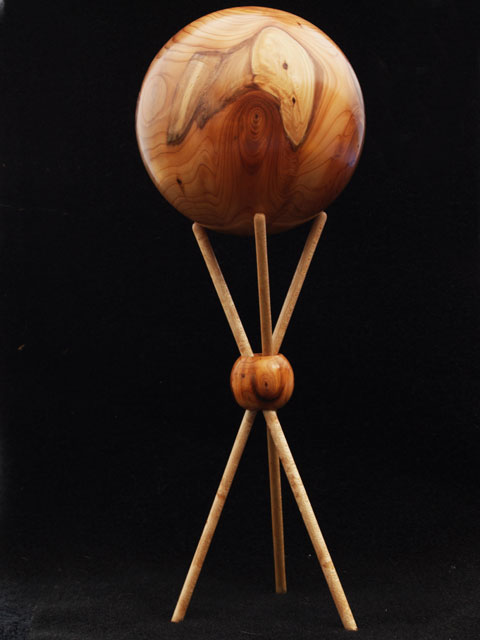

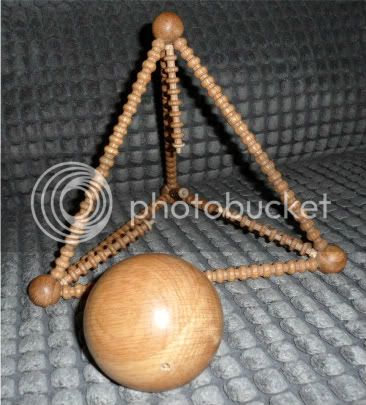

Hi everyone , out project for the 2012 February Challenge is A Suspended Ball ( from above or below )

Our Judge for February will be Richard

Must be New work for this Challenge

The suspended ball must be a minimum of 50mm and a maximum of 100mm ( 2" - 4" )

No restrictions re size or amount of components used in the construction of the means of suspension ( from above or below )

No part of the ball is allowed to sit on the ground / base , It mist be suspended

All components are to be lathe turned and made of wood , NO metal items to be used ( screws , nails , chain etc )

You are allowed to use glue for the assembly of your entry

You are allowed to drill holes , any size and angle , any amount, as long as it is for construction purposes only and not for decorative features

Any wood type

No colouring / texturing / burning / piercing allowed

Any entry's that are outside the rules and requirements will not be judged

Richards Criteria:

I will be looking for creativity in meeting the brief, quality of the execution including "roundness" of the ball and quality of finish and appropriate use of the timber.

The Judges decision is final ( Any negative comments re judging must be via PM only and not on the open forum )

NO Critique or comments on any work until March Please, After the Judging and results.

Please state wood type if known, dimensions and a little about how you made it and what tools and finish you used ( this helps the judge )

Please post 3 images of your work / entry

1 showing all elements of you entry prior to assembly / construction

1 showing your entry assembled ( With the ball suspended ( from above or below ) in position

1 showing your assembled entry with the ball not suspended but standing next to the assembly

Image size please use image size 640 x 480 0.3 mp, same previous months

When your entry is ready please go to our new scoreboard http://ukwturningcomp.co.uk/

Log in to your account and mark yourself as ready by 10 pm on the 25th February after this time the scoreboard will be locked

Entry’s to be uploaded from 10pm on 25th February up until 10pm on the 27th February. after this time the thread will be locked for Judging

Results will be given on or before 29 February ( Leap year :mrgreen: )

I hope you all have fun with this challenge , Good luck

Our Judge for February will be Richard

Must be New work for this Challenge

The suspended ball must be a minimum of 50mm and a maximum of 100mm ( 2" - 4" )

No restrictions re size or amount of components used in the construction of the means of suspension ( from above or below )

No part of the ball is allowed to sit on the ground / base , It mist be suspended

All components are to be lathe turned and made of wood , NO metal items to be used ( screws , nails , chain etc )

You are allowed to use glue for the assembly of your entry

You are allowed to drill holes , any size and angle , any amount, as long as it is for construction purposes only and not for decorative features

Any wood type

No colouring / texturing / burning / piercing allowed

Any entry's that are outside the rules and requirements will not be judged

Richards Criteria:

I will be looking for creativity in meeting the brief, quality of the execution including "roundness" of the ball and quality of finish and appropriate use of the timber.

The Judges decision is final ( Any negative comments re judging must be via PM only and not on the open forum )

NO Critique or comments on any work until March Please, After the Judging and results.

Please state wood type if known, dimensions and a little about how you made it and what tools and finish you used ( this helps the judge )

Please post 3 images of your work / entry

1 showing all elements of you entry prior to assembly / construction

1 showing your entry assembled ( With the ball suspended ( from above or below ) in position

1 showing your assembled entry with the ball not suspended but standing next to the assembly

Image size please use image size 640 x 480 0.3 mp, same previous months

When your entry is ready please go to our new scoreboard http://ukwturningcomp.co.uk/

Log in to your account and mark yourself as ready by 10 pm on the 25th February after this time the scoreboard will be locked

Entry’s to be uploaded from 10pm on 25th February up until 10pm on the 27th February. after this time the thread will be locked for Judging

Results will be given on or before 29 February ( Leap year :mrgreen: )

I hope you all have fun with this challenge , Good luck