jimi43

Established Member

I think it is no exaggeration to say that I have tried every type of object capable of making something blunt, sharp. Making something raw, bevelled. From my concrete step to the delicate finishing of Ardennes' finest coticule.

But like most other people, I search in vain for the holy grail...the sharpening thing that does everything.

Well a fine company in Sweden may very well be coming close to providing that utopia.

I stumbled on the Fällkniven factory when researching sharpening systems to put a new edge on some knives my son (a chef) owns from Global...which tend to be rather hard to sharpen...resisting most methods thrown at them. So the other day I was trawling FleaBay and came across this product and thought it looked pretty anyway and I should try it.

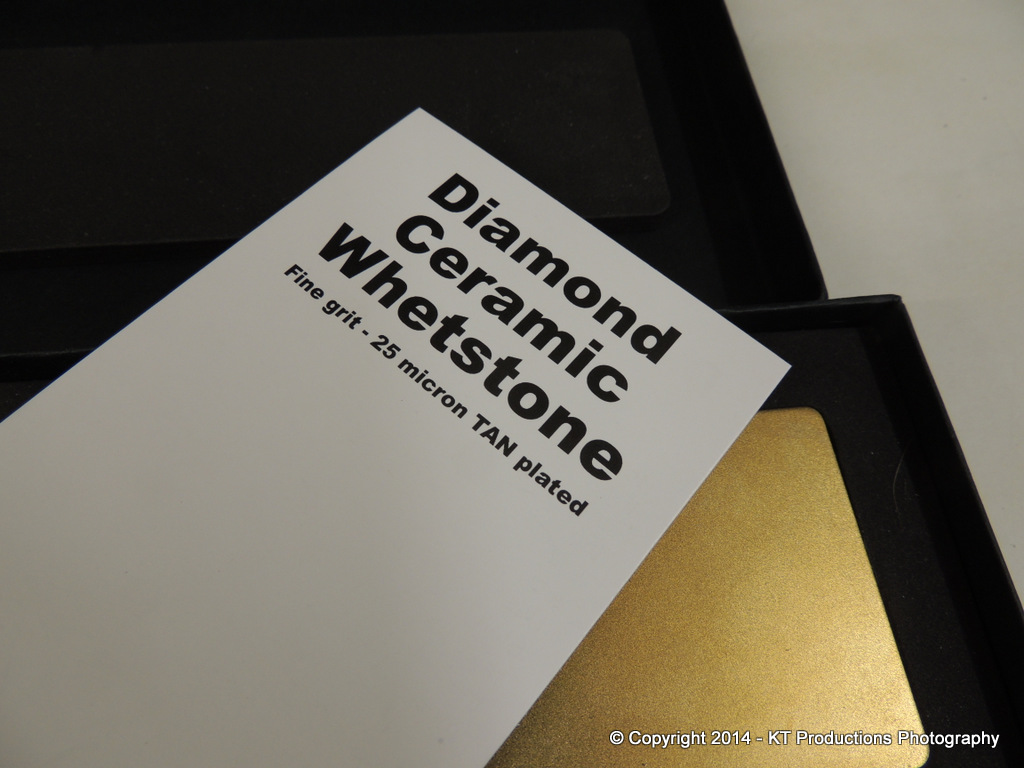

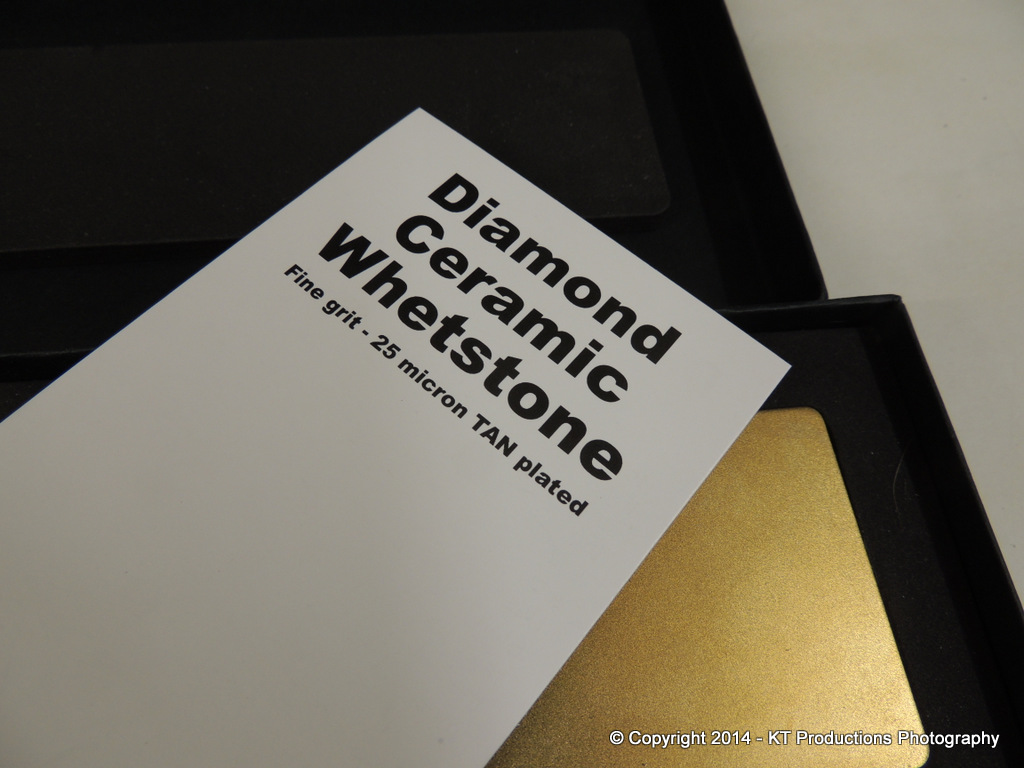

It arrived very quickly...a day or two...beautifully packaged and in a rather nice box...

It's unusual in that it has a base ceramic in black with a steel TAN coated plate bonded to this. The gold plate is a very coarse diamond "stone" and the black substrate is a "fine" ceramic stone...made of synthetic sapphires.

I put "fine" in quotes because it isn't! It's medium at best and bloody aggressive in reality. Which is what I loved! All the ceramic stones I have ever tried are ok for fine work but not for that medium stage between copious stock removal and fine honing.

This ceramic stone fills that gap perfectly.

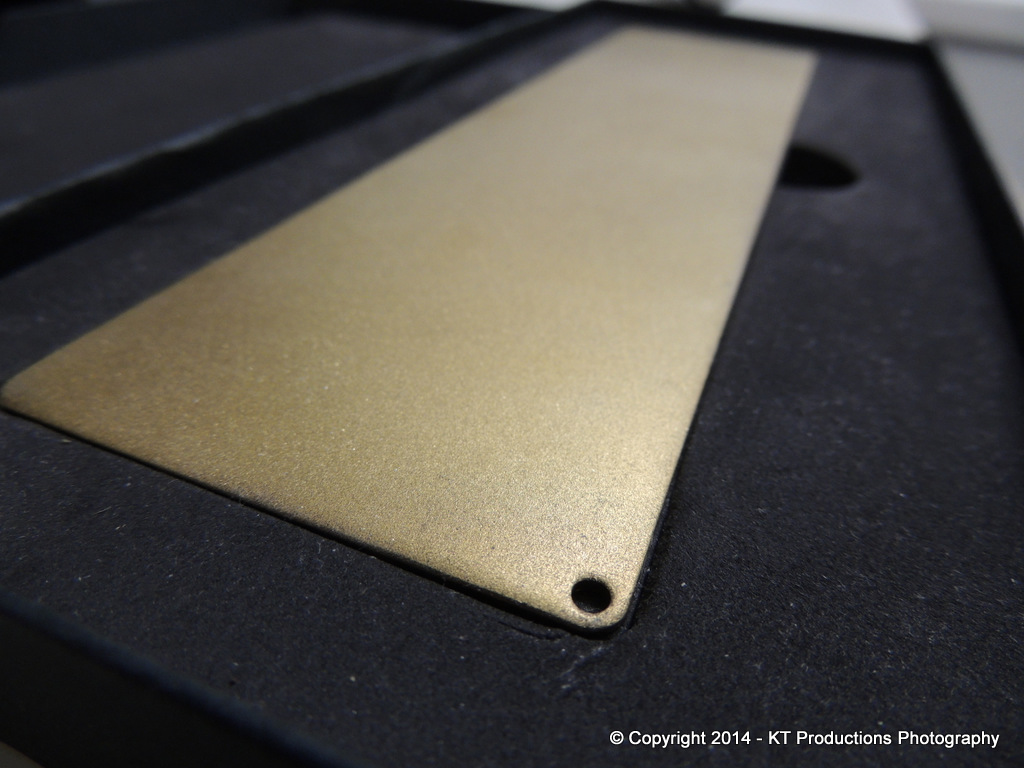

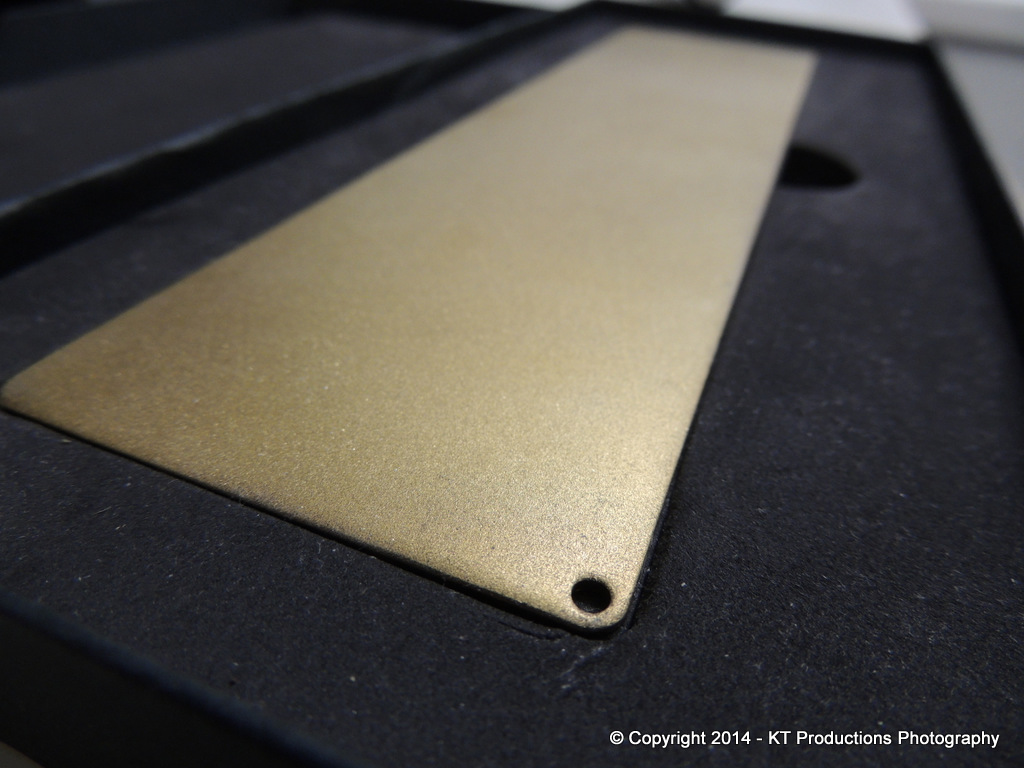

That's the diamond side...no idea what the hole is for...probably hanging it up...but you want to put it back in the box it's so beautiful!

The other side which is for finishing is a weird surface...

You use both sides dry and really...it works! You just brush the dry dust off but don't use your T-shirt...I put a hole straight through the material with a few swipes it is that good!

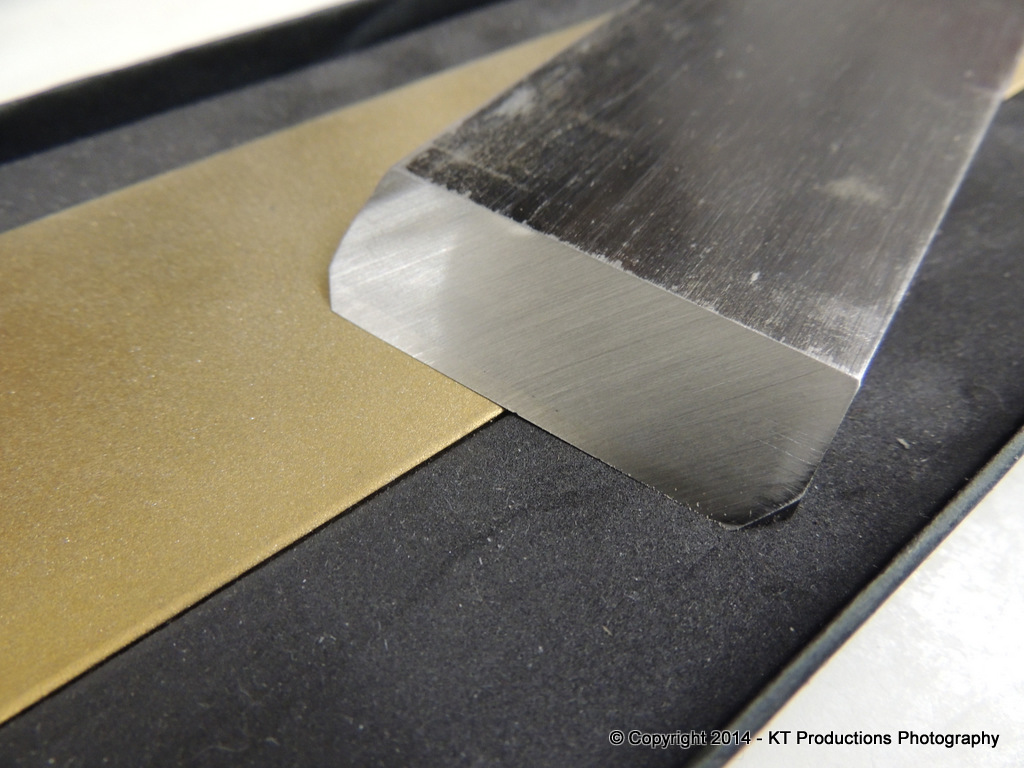

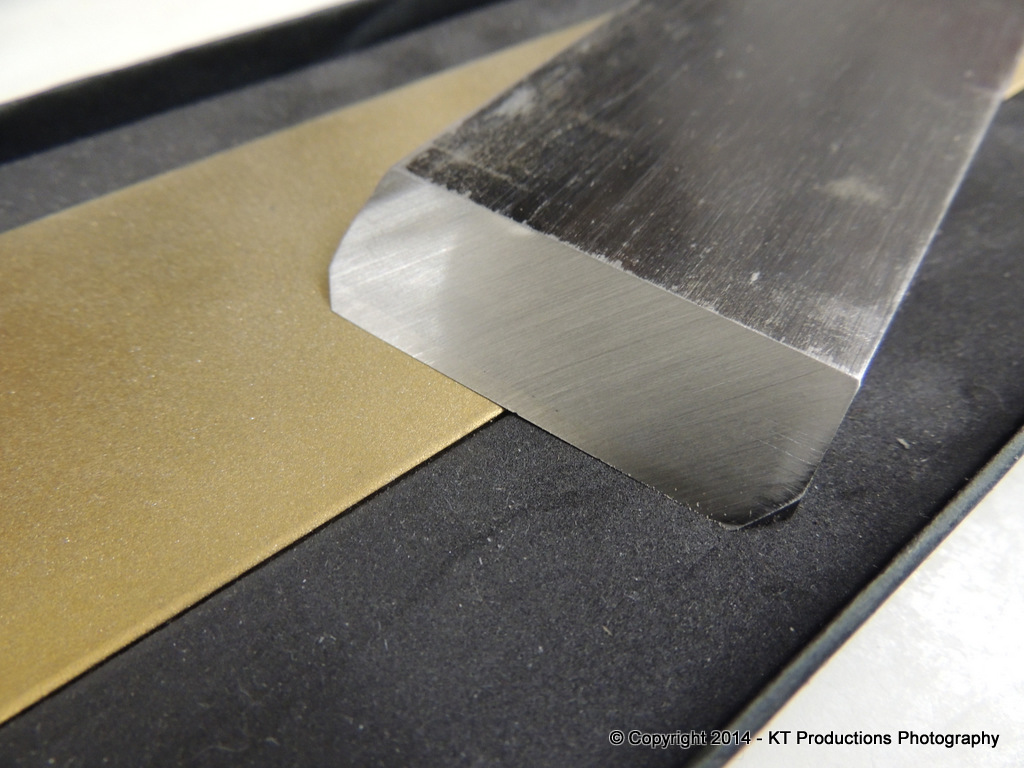

It sort of came at the right time...that Japanese iron on the Steve Knight jointer was in need of flattening and the bevel finishing so that was the first thing I did....

The edge had quite a big chip out of it...one of the bugbears of the super-hard Japanese edge laminate. I wanted to get rid of it...and nearly have in a few minute!

Just a bit more to go but I was impatient to try out the Knight jointer so I will come back and finish it later when I have a few seconds!!

That re-shaping was done with confidence totally by hand...no guide...and gives a really professional finish.

I can't wait to start sharpening all the knives in the kitchen and at my son's work!!!

I have already had to warn Annie that the little Victorian veg knife I keep on the side is now a lethal weapon....

This stone is truly that good.....and worth every penny of the £50 it costs...it puts the more expensive DMT stones to shame!

Cheers

Jimi

PS...ALFIE was NOT harmed in the making of this review!!!

But like most other people, I search in vain for the holy grail...the sharpening thing that does everything.

Well a fine company in Sweden may very well be coming close to providing that utopia.

I stumbled on the Fällkniven factory when researching sharpening systems to put a new edge on some knives my son (a chef) owns from Global...which tend to be rather hard to sharpen...resisting most methods thrown at them. So the other day I was trawling FleaBay and came across this product and thought it looked pretty anyway and I should try it.

It arrived very quickly...a day or two...beautifully packaged and in a rather nice box...

It's unusual in that it has a base ceramic in black with a steel TAN coated plate bonded to this. The gold plate is a very coarse diamond "stone" and the black substrate is a "fine" ceramic stone...made of synthetic sapphires.

I put "fine" in quotes because it isn't! It's medium at best and bloody aggressive in reality. Which is what I loved! All the ceramic stones I have ever tried are ok for fine work but not for that medium stage between copious stock removal and fine honing.

This ceramic stone fills that gap perfectly.

That's the diamond side...no idea what the hole is for...probably hanging it up...but you want to put it back in the box it's so beautiful!

The other side which is for finishing is a weird surface...

You use both sides dry and really...it works! You just brush the dry dust off but don't use your T-shirt...I put a hole straight through the material with a few swipes it is that good!

It sort of came at the right time...that Japanese iron on the Steve Knight jointer was in need of flattening and the bevel finishing so that was the first thing I did....

The edge had quite a big chip out of it...one of the bugbears of the super-hard Japanese edge laminate. I wanted to get rid of it...and nearly have in a few minute!

Just a bit more to go but I was impatient to try out the Knight jointer so I will come back and finish it later when I have a few seconds!!

That re-shaping was done with confidence totally by hand...no guide...and gives a really professional finish.

I can't wait to start sharpening all the knives in the kitchen and at my son's work!!!

I have already had to warn Annie that the little Victorian veg knife I keep on the side is now a lethal weapon....

This stone is truly that good.....and worth every penny of the £50 it costs...it puts the more expensive DMT stones to shame!

Cheers

Jimi

PS...ALFIE was NOT harmed in the making of this review!!!