BTR

Established Member

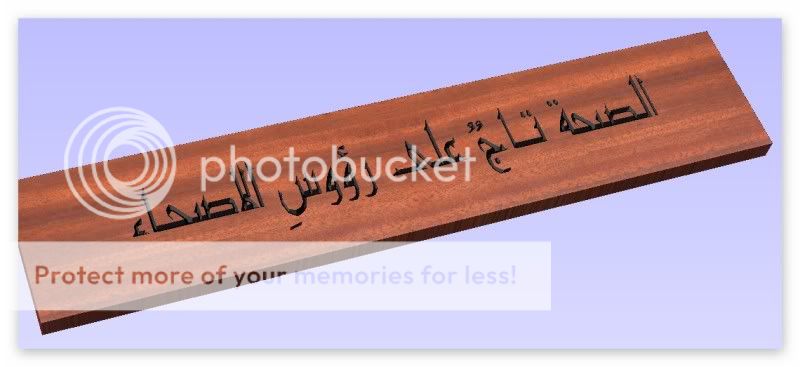

I have been asked by a freind to do him some wooden plaque's with some letters in Arabic for him these plaques will vari in size from 6'' long by 3'' wide to 36'' by 40'' so the wording will have to be different sizes.

The writing is very complex see the attached link can you please help me and tell me the best way to acheive this would be, also just to make this that extra bit special some of the engraving on the plaques i would like to fill with some sort of resin to give it a contrasting look to the wood i will be useing oak ,abw and ash thanks.

The writing is very complex see the attached link can you please help me and tell me the best way to acheive this would be, also just to make this that extra bit special some of the engraving on the plaques i would like to fill with some sort of resin to give it a contrasting look to the wood i will be useing oak ,abw and ash thanks.